In short, the vibrant colors you see in a thin film, like an oil slick or soap bubble, typically appear when the film is between 200 and 600 nanometers thick. While the general definition of a thin film can range from a single layer of atoms (fractions of a nanometer) to several micrometers, the specific phenomenon of visible color occurs within this much narrower, nanometer-scale range.

The most critical takeaway is that the color of a thin film is not caused by pigment. It is a physical phenomenon of light interference, where the film's exact thickness dictates which specific color of light is reflected to your eye.

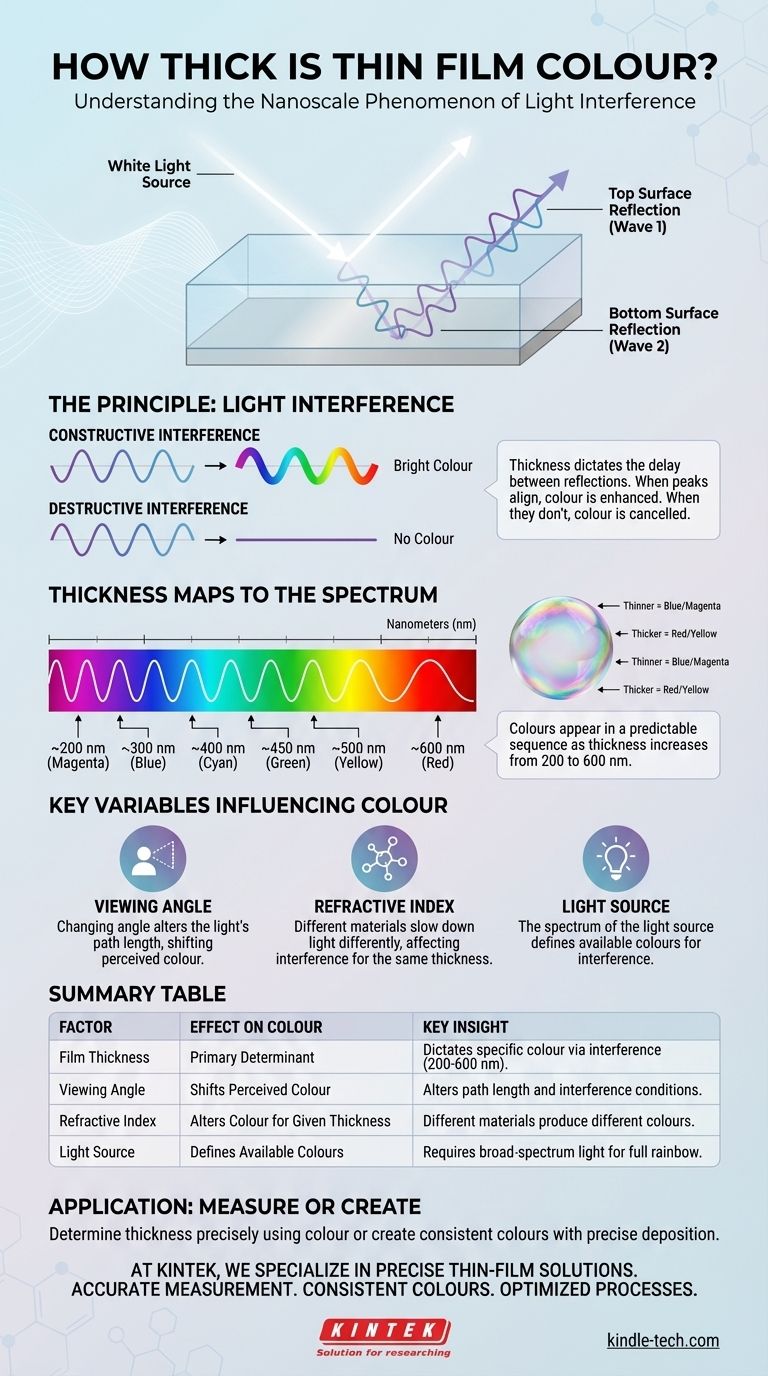

The Principle: How Thickness Creates Color

The question isn't just about a specific number, but about why a certain thickness produces a certain color. This effect, known as thin-film interference, is based on the wave-like properties of light.

Light Reflects Twice

When light strikes a transparent thin film, it doesn't just reflect once. A portion of the light reflects off the top surface of the film.

The rest of the light passes through the film and reflects off the bottom surface before traveling back up.

Waves Interact Through Interference

You now have two light waves traveling back to your eye: one from the top surface and one from the bottom. The wave that traveled through the film is slightly delayed.

This delay causes the two waves to interfere with each other.

Constructive and Destructive Interference

If the peaks of the two reflected waves align, they amplify each other. This is called constructive interference, and it makes that specific color appear bright and vivid.

If the peak of one wave aligns with the trough of another, they cancel each other out. This is destructive interference, and it effectively removes that color from the light you see.

Thickness is the Deciding Factor

The thickness of the film is the crucial variable. It determines the length of the delay for the second light wave.

A specific thickness will cause constructive interference for one color (e.g., blue) and destructive interference for others (e.g., red). This is why you see a distinct color. As the thickness changes, the color you see changes with it.

Mapping Thickness to the Color Spectrum

The rainbow-like patterns you see on a soap bubble or an oil slick are a perfect map of changing film thickness.

A Predictable Sequence of Colors

As the thickness of a film gradually increases, the condition for constructive interference is met for different colors in a predictable order, following the visible spectrum.

A very thin film might first appear magenta, then blue, then cyan, green, yellow, and red as its thickness steadily increases by hundreds of nanometers.

The Soap Bubble Example

A soap bubble is thickest at the bottom and thinnest at the top due to gravity. This is why you see bands of color that correspond to these bands of consistent thickness.

As the bubble thins over time, you can see the color bands move and change, providing a real-time visual of its changing thickness.

Key Variables That Change the Color

While thickness is the primary driver, other factors influence the final color you perceive. A professional must account for these variables.

The Viewing Angle

The color of a thin film can change as you alter your viewing angle. Changing the angle changes the path length of the light traveling within the film, which in turn changes the interference conditions.

This is why the colors on an oil slick seem to shimmer and shift as you move your head.

The Material's Refractive Index

Every transparent material has a refractive index, which measures how much it slows down light. This property directly affects the interference conditions.

A 400-nanometer film of silicon dioxide will produce a different color than a 400-nanometer film of titanium oxide because their refractive indices are different.

The Light Source

The perceived color is entirely dependent on the light source. The principles described here assume a white light source, which contains all colors.

If you view a thin film under a single-color light (like a yellow sodium lamp), you won't see a rainbow. You will only see bands of bright yellow (constructive interference) and black (destructive interference).

How to Apply This Knowledge

Understanding this relationship between thickness and color is a powerful tool in science and engineering.

- If your primary focus is determining thickness: You can use the observed color as a remarkably accurate measurement tool, provided you know the material's refractive index and keep the viewing angle consistent.

- If your primary focus is creating a specific color: You must use a deposition process that can precisely control film thickness down to the single-nanometer level to achieve a consistent, repeatable color.

By grasping this, you can interpret the shimmering colors on a surface not as a simple coating, but as a precise map of its nanoscale topography.

Summary Table:

| Factor | Effect on Colour | Key Insight |

|---|---|---|

| Film Thickness | Primary determinant | Colour appears between 200-600 nm; specific thickness dictates specific colour via interference. |

| Viewing Angle | Shifts perceived colour | Changing the angle alters the light's path length, changing interference conditions. |

| Refractive Index | Alters colour for a given thickness | Different materials (e.g., SiO₂ vs. TiO₂) produce different colours at the same thickness. |

| Light Source | Defines available colours for interference | Requires a broad-spectrum (white) light source to produce a full rainbow of colours. |

Need to precisely measure or create nanoscale thin films?

At KINTEK, we specialize in the advanced lab equipment and consumables required for precise thin-film deposition and analysis. Whether you are developing optical coatings, semiconductors, or specialised surfaces, controlling thickness at the nanoscale is critical for achieving your desired results.

Our expertise and product solutions can help you:

- Accurately measure film thickness using reliable, industry-standard techniques.

- Achieve consistent, vibrant colours or specific optical properties through precise deposition control.

- Optimise your processes with high-quality materials and equipment tailored to your laboratory's needs.

Let's discuss your project. Contact our experts today to find the perfect solution for your thin-film applications.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Benchtop Laboratory Vacuum Freeze Dryer

- Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- Is sputtering a PVD? Discover the Key Coating Technology for Your Lab

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis