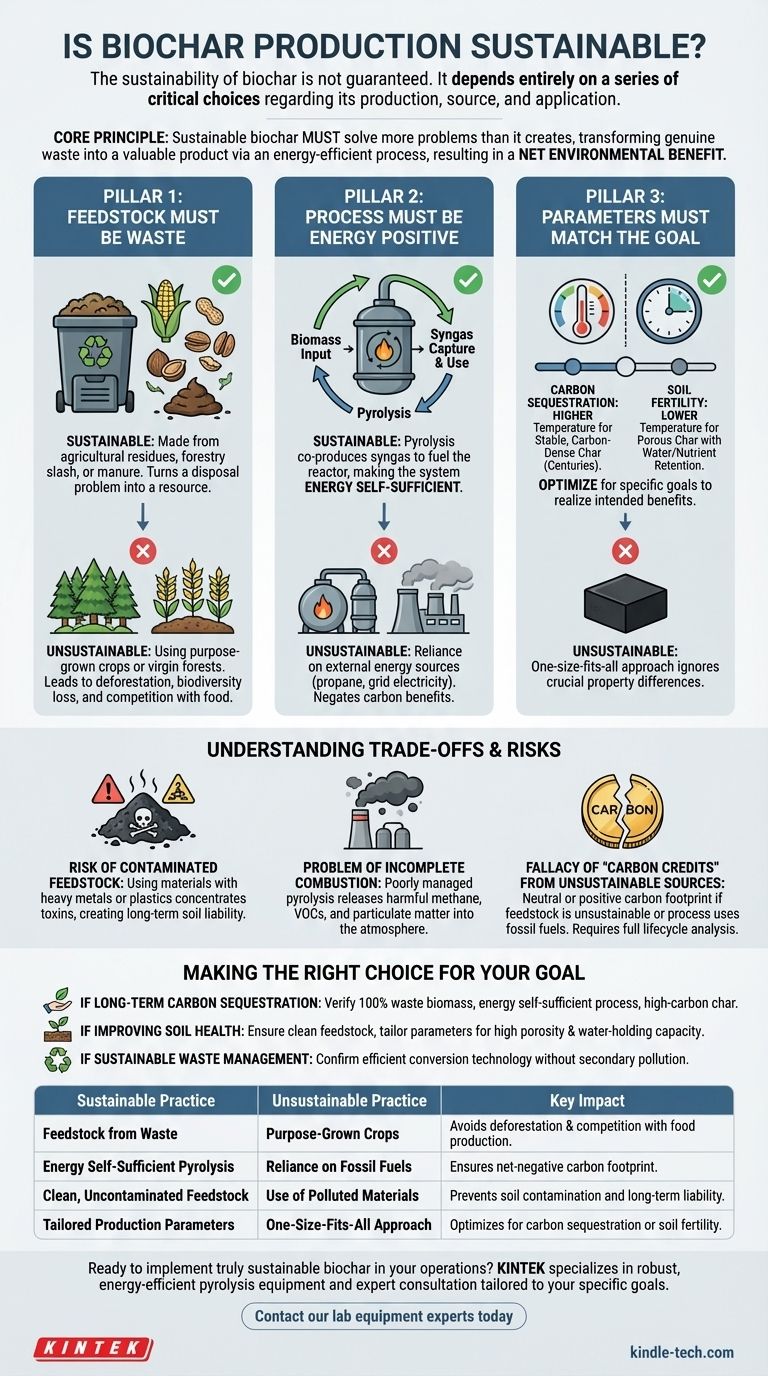

The sustainability of biochar is not guaranteed. Its environmental benefit depends entirely on a series of critical choices regarding how it is made, what it is made from, and how it is used. When produced correctly from waste materials, it is a powerful tool for carbon sequestration and soil regeneration; when produced poorly, it can be a net source of emissions and a potential soil contaminant.

The core principle of sustainable biochar is that it must solve more problems than it creates. This is achieved only when it transforms a genuine waste stream into a valuable product using an energy-efficient process, resulting in a net environmental benefit.

The Pillars of Sustainable Biochar Production

Biochar's sustainability is not an inherent property but an outcome of a carefully managed system. Three factors are paramount: the source of the biomass, the energy balance of the production process, and the final application.

Pillar 1: The Feedstock Must Be Waste

The single most important factor is the source material, known as feedstock. Sustainable biochar is made from materials that would otherwise be considered waste.

This includes agricultural residues like corn stover, forestry slash, nut shells, or manure. Using these materials turns a disposal problem into a valuable resource.

Conversely, using purpose-grown crops or harvesting virgin forests for biochar production is fundamentally unsustainable. This can lead to deforestation, biodiversity loss, and competition with food production.

Pillar 2: The Process Must Be Energy Positive

Biochar is created through pyrolysis, a process of heating biomass in a low-oxygen environment. This process requires an initial energy input.

A sustainable operation powers itself. Pyrolysis co-produces a flammable gas (syngas) that can be captured and used to fuel the reactor, eliminating the need for fossil fuels and making the system energy self-sufficient.

Inefficient or poorly designed systems may rely on external energy sources like propane or electricity from the grid, which can negate the carbon benefits of the entire process.

Pillar 3: The Parameters Must Match the Goal

The specific production parameters—primarily temperature and heating time—dramatically alter the final properties of the biochar. As the references note, this variability is a key challenge.

For carbon sequestration, a higher pyrolysis temperature creates a more stable, carbon-dense biochar that will persist in the soil for centuries.

For improving soil fertility, a lower temperature may be chosen to create a more porous biochar with properties better suited for retaining water and nutrients. Optimizing for a specific goal is critical to realizing the intended benefits.

Understanding the Trade-offs and Risks

A clear-eyed assessment of biochar requires understanding the potential pitfalls that can render a project unsustainable. Ignoring these risks can lead to negative environmental outcomes.

The Risk of Contaminated Feedstock

Using contaminated feedstock is a critical failure point. If the source material contains heavy metals, plastics, treated wood, or other pollutants, those contaminants will become concentrated in the final biochar.

Applying this contaminated biochar to land can introduce persistent toxins into the soil, harming microbial life, poisoning crops, and creating a long-term environmental liability.

The Problem of Incomplete Combustion

Poorly managed pyrolysis can result in incomplete combustion, releasing harmful pollutants like methane, volatile organic compounds (VOCs), and particulate matter into the atmosphere.

Modern, well-engineered pyrolysis systems are designed to capture and burn these compounds, using them as fuel while preventing air pollution. Outdated or simple "backyard" methods often fail this crucial test.

The Fallacy of "Carbon Credits" from Unsustainable Sources

Simply making biochar does not automatically create a carbon benefit. If the feedstock was sourced unsustainably or the process used fossil fuels, the project may have a neutral or even positive carbon footprint, despite locking some carbon in the biochar itself.

Authentic carbon sequestration requires a full lifecycle analysis that proves the entire system, from sourcing to application, is net-negative.

Making the Right Choice for Your Goal

To determine if a specific biochar or production method is truly sustainable, you must evaluate it based on its entire lifecycle and your specific objective.

- If your primary focus is long-term carbon sequestration: You must verify the feedstock is 100% waste biomass and the production process is energy self-sufficient, creating a stable, high-carbon char.

- If your primary focus is improving soil health: You must ensure the feedstock is clean and uncontaminated and that the pyrolysis parameters are tailored to create biochar with high porosity and water-holding capacity.

- If your primary focus is sustainable waste management: You must confirm the technology can efficiently convert a specific waste stream into a safe, valuable product without creating secondary pollution issues.

Ultimately, sustainable biochar is the result of a deliberate, well-designed system, not just a product.

Summary Table:

| Sustainable Practice | Unsustainable Practice | Key Impact |

|---|---|---|

| Feedstock from Waste (e.g., agricultural residues) | Purpose-Grown Crops | Avoids deforestation & competition with food production. |

| Energy Self-Sufficient Pyrolysis | Reliance on Fossil Fuels | Ensures net-negative carbon footprint. |

| Clean, Uncontaminated Feedstock | Use of Polluted Materials | Prevents soil contamination and long-term liability. |

| Tailored Production Parameters | One-Size-Fits-All Approach | Optimizes for carbon sequestration or soil fertility. |

Ready to implement truly sustainable biochar in your operations?

KINTEK specializes in providing robust, energy-efficient pyrolysis equipment and expert consultation tailored to your specific goals—whether for carbon sequestration, soil regeneration, or sustainable waste management. Our solutions are designed to help you transform genuine waste streams into valuable, safe biochar, ensuring a net environmental benefit.

Contact our lab equipment experts today to discuss how we can support your sustainable biochar project from feedstock to final application.

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What is the role of the hydraulic system in hot pressing? Achieve Maximum Material Density and Strength

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- How mechanical properties are affected by sintering? Master the Trade-offs for Stronger Materials

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- How does a vacuum oven contribute to solid electrolyte membrane formation? Achieve Dense, Defect-Free Materials