In short, yes, but it is not a simple conductor. Standard carbon fiber filament is electrically conductive, but its level of conductivity is very low compared to metals. It is more accurately described as a statically dissipative material, meaning it is capable of bleeding off static charge but is not suitable for carrying significant electrical current like a wire.

The core misunderstanding is treating carbon fiber filament as a replacement for metal wire. Instead, you must think of it as an anti-static plastic. Its primary electrical purpose is to prevent the sudden discharge of static electricity, making it ideal for protecting sensitive electronics.

From Insulator to Conductor: A Spectrum of Materials

To properly use carbon fiber filament, you must understand where it sits on the spectrum of electrical materials, which is fundamentally different from the standard plastics used in 3D printing.

Standard 3D Printing Plastics are Insulators

Common filaments like PLA, PETG, and ABS are electrical insulators. They have very high electrical resistance, which prevents electricity from flowing through them. This is why they can build up a significant static charge on their surface.

The Role of Carbon Fiber Additives

"Carbon fiber filament" is not pure carbon fiber. It is a composite material made from a base plastic (like Nylon, PETG, or PLA) that has been infused with small, chopped strands of carbon fiber.

These carbon fibers create a conductive matrix within the otherwise insulating plastic. This allows electrical charge to move through the part, albeit not very efficiently.

"Conductive" vs. "Dissipative"

These terms are not interchangeable, and the distinction is critical for engineering applications.

- Conductive materials have very low electrical resistance, allowing current to flow easily. Metals like copper are highly conductive.

- Dissipative materials have a moderate level of electrical resistance. They allow static charge to flow to ground in a slow, controlled manner, preventing a sudden, damaging spark.

- Insulative materials have very high electrical resistance and are used to block the flow of electricity entirely.

Carbon fiber 3D printing filament falls squarely in the dissipative category. It is conductive enough to ground static electricity but far too resistive for carrying power.

Practical Applications for Electrical Properties

Understanding that the material is dissipative, not truly conductive, clarifies its proper use cases and reveals what it cannot be used for.

The Primary Use: Electrostatic Discharge (ESD) Protection

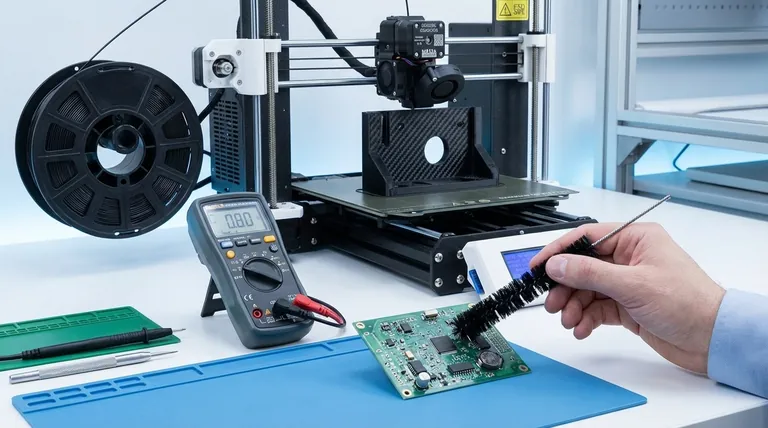

The single most important electrical application for this material is creating ESD-safe parts. Sensitive electronic components can be destroyed by a tiny spark of static electricity from your body or a plastic tool.

By printing jigs, fixtures, enclosures, or assembly tools from carbon fiber filament, you create an object that will safely bleed any static charge to ground, protecting the components it touches.

Unsuitable for Circuits or Wiring

You cannot print a functional electrical circuit or wire with carbon fiber filament. Its resistance is thousands or even millions of times higher than copper. Attempting to pass significant current through it will simply generate heat and fail.

Limited RF Shielding

The conductive network of carbon fibers can provide a degree of RF (Radio Frequency) shielding, sometimes referred to as a Faraday cage. This can be useful for enclosures that need to block electromagnetic interference. However, its effectiveness is limited and varies greatly between filament brands and print geometries.

Understanding the Trade-offs and Limitations

Before using carbon fiber filament, you must be aware of its specific requirements and inconsistencies.

Conductivity is Not Guaranteed or Uniform

The electrical properties are highly dependent on the brand of filament, the percentage of carbon fiber fill, and the base plastic used. A Nylon-based carbon fiber filament will have different properties than one based on PLA. Always check the manufacturer's technical data sheet for specific resistivity values.

Print Settings Impact Performance

The final conductivity of your part is affected by your slicer settings. Higher print temperatures can sometimes improve the connection between fibers, while the orientation of the printed layers can create paths of higher or lower resistance.

It Requires a Specialized Printer Setup

Carbon fiber filament is extremely abrasive. It will rapidly wear out a standard brass nozzle, often in a single print. You must use a hardened steel, ruby, or other abrasion-resistant nozzle to print with this material successfully.

Making the Right Choice for Your Application

Use these guidelines to determine if carbon fiber filament is the correct material for your project.

- If your primary focus is creating ESD-safe jigs and enclosures: This is the ideal material, as its dissipative properties are specifically suited for protecting sensitive electronics.

- If your primary focus is printing electrical circuits or wires: This material is entirely unsuitable due to its high electrical resistance. Look into specialized, highly conductive filaments instead.

- If your primary focus is mechanical strength and light weight: Carbon fiber filament is an excellent choice, but be aware of its electrical properties and do not use it in high-voltage applications where you need true insulation.

By understanding carbon fiber filament as a specialized dissipative material, you can leverage its unique electrical properties for advanced manufacturing applications.

Summary Table:

| Property | Carbon Fiber Filament | Standard PLA/ABS | Metal (e.g., Copper) |

|---|---|---|---|

| Electrical Classification | Static Dissipative | Insulator | Conductor |

| Primary Electrical Use | ESD Protection | N/A (Builds static charge) | Carrying Current |

| Resistance | High (kΩ to MΩ range) | Very High (insulating) | Very Low (conductive) |

Need ESD-safe components or expert advice on lab materials? KINTEK specializes in high-performance lab equipment and consumables. Our team can help you select the right materials for your sensitive electronics manufacturing or research. Contact our experts today to discuss your specific application and ensure optimal protection and performance.

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the recommended cleaning procedure for a carbon fiber brush after use? Extend Brush Life and Maintain Performance

- What are 3 types of biomass? A Guide to Wood, Waste, and Biofuels for Energy

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice

- What checks should be performed on a carbon fiber brush before use? Ensure Reliability in Your Lab Processes

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity