In principle, yes. Hydrogen produced through the gasification of biomass is categorized as green hydrogen. This classification stems from its use of renewable, biogenic feedstocks—such as wood or agricultural waste—as a starting material, positioning it as a direct replacement for processes that rely on fossil fuels.

While hydrogen from biomass gasification is officially classified as a "green" option, its true climate neutrality is not automatic. The "green" label is conditional, depending entirely on the sustainability of the biomass source and the full lifecycle of the production process.

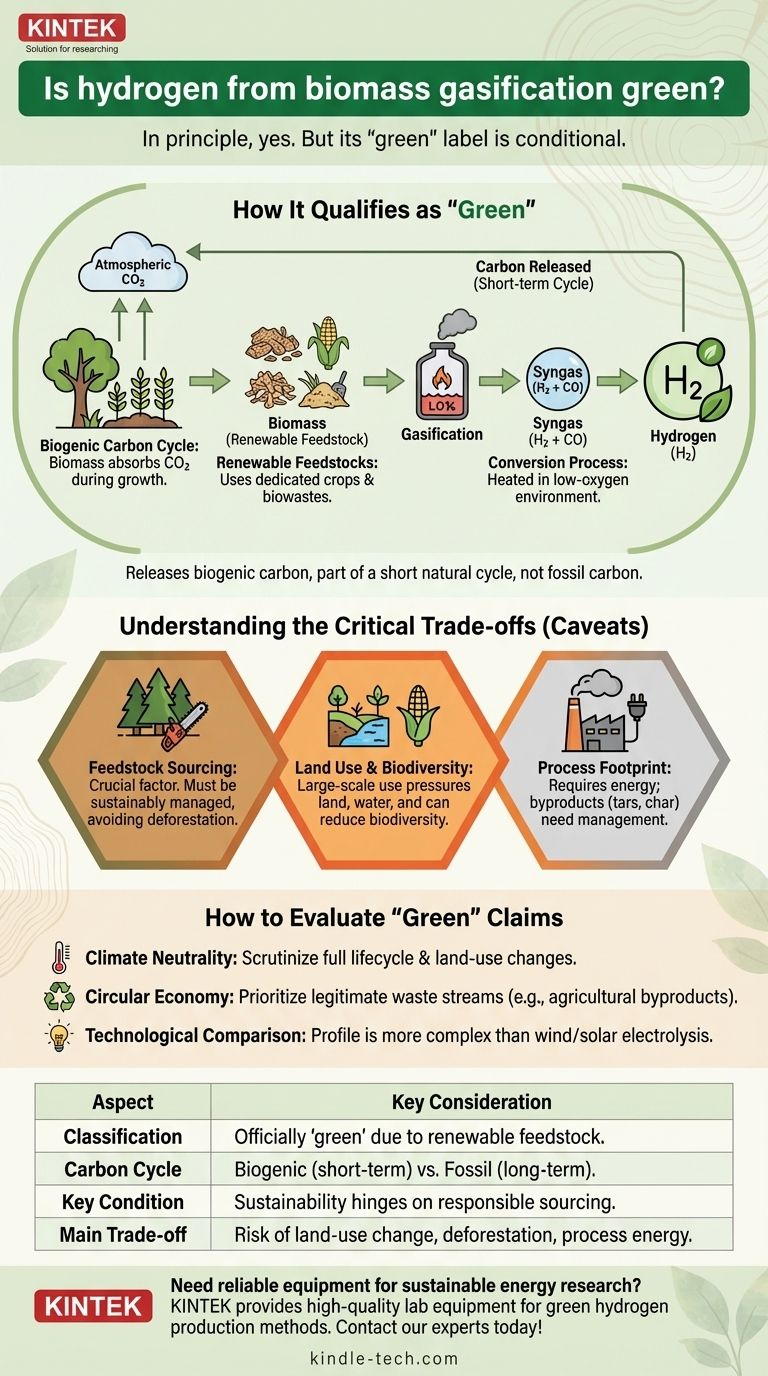

How Biomass Gasification Qualifies as "Green"

To understand why this method is considered a green pathway, we need to look at the underlying principles of its carbon cycle and feedstock.

The Biogenic Carbon Cycle

The core concept is that biomass, like trees or crops, absorbs carbon dioxide (CO2) from the atmosphere during its growth.

When this biomass is converted into hydrogen, the carbon it contains is released back into the atmosphere. This is seen as part of a relatively short-term, natural cycle—unlike releasing carbon that has been trapped underground for millions of years from fossil fuels.

Utilizing Renewable Feedstocks

The process relies on renewable resources, not finite fossil fuels.

This includes dedicated energy crops, forestry byproducts, and various biowastes from agriculture or municipalities. Using waste streams, in particular, enhances its environmental credentials by converting a low-value material into a high-value energy carrier.

The Conversion Process

Biomass gasification involves heating the solid biomass in a low-oxygen environment to produce a mixture of gases known as synthesis gas (syngas).

This syngas, rich in hydrogen and carbon monoxide, is then further processed through chemical reactions to maximize the hydrogen yield and separate it for use as a clean fuel.

Understanding the Critical Trade-offs

The "green" designation comes with significant caveats. Acknowledging these nuances is essential for an objective evaluation of this technology's environmental impact.

Feedstock Sourcing is Everything

The single most important factor is where the biomass comes from. Using agricultural residues or waste from sustainably managed forests is fundamentally different from clear-cutting old-growth forests for fuel.

If the demand for biomass leads to deforestation or competition with food crops for land, the process can no longer be considered truly green or sustainable.

Land Use and Biodiversity Impacts

A large-scale reliance on biomass for hydrogen could place immense pressure on land and ecosystems.

This raises critical questions about soil health, water use, and the potential for monoculture farming to reduce biodiversity, which must be carefully managed to avoid negative consequences.

The Process Has Its Own Footprint

The gasification facility itself requires energy to operate. The overall carbon footprint of the hydrogen produced depends on whether this operational energy comes from renewable sources or from the grid.

Furthermore, the process is not perfectly clean and can produce byproducts like tars and char, which require proper management.

How to Evaluate "Green" Claims for Biomass Hydrogen

The context behind the production method is more important than the simple color-coded label. Use these points to guide your assessment.

- If your primary focus is climate neutrality: Scrutinize the full lifecycle of the biomass feedstock to ensure it is sustainably harvested and does not cause indirect emissions through land-use change.

- If your primary focus is a circular economy: Prioritize projects that exclusively use legitimate waste streams, such as agricultural byproducts or non-recyclable municipal biowaste.

- If your primary focus is technological comparison: Acknowledge that while categorized as green, its environmental profile is often more complex than that of green hydrogen produced via electrolysis powered by wind or solar.

Ultimately, hydrogen from biomass gasification holds potential as a green energy source, but its legitimacy hinges on a transparent and responsible supply chain.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Classification | Officially categorized as 'green' hydrogen due to renewable feedstock. |

| Carbon Cycle | Uses biogenic carbon (short-term cycle) vs. fossil carbon (long-term). |

| Key Condition | Sustainability hinges entirely on responsible biomass sourcing. |

| Main Trade-off | Risk of land-use change, deforestation, and process energy footprint. |

Need reliable equipment for your sustainable energy research?

At KINTEK, we provide the high-quality lab equipment and consumables you need to develop and analyze green hydrogen production methods like biomass gasification. Our products help ensure the accuracy and efficiency of your research into sustainable feedstocks and process optimization.

Contact our experts today to discuss how we can support your laboratory's contribution to a cleaner energy future.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages and disadvantages of pyrolysis? Unlocking Value from Waste vs. Cost & Complexity

- What are the two types of carbon residue produced by pyrolysis? Amorphous Char vs. Structured Nanotubes

- How does pyrolysis help the environment? Transform Waste into Renewable Energy and Carbon Sequestration

- What type of plastic is used in pyrolysis? Turn Diverse Plastic Waste into Valuable Resources

- Where can we use pyrolysis oil? Unlock its potential as a renewable fuel and chemical feedstock.

- What is the energy efficiency of a rotary kiln? Achieve 95%+ Thermal Efficiency

- What is the theory of calcination? Master Precise Thermal Decomposition for Your Materials

- What are the disadvantages of a variable speed furnace? Higher Cost vs. Superior Comfort