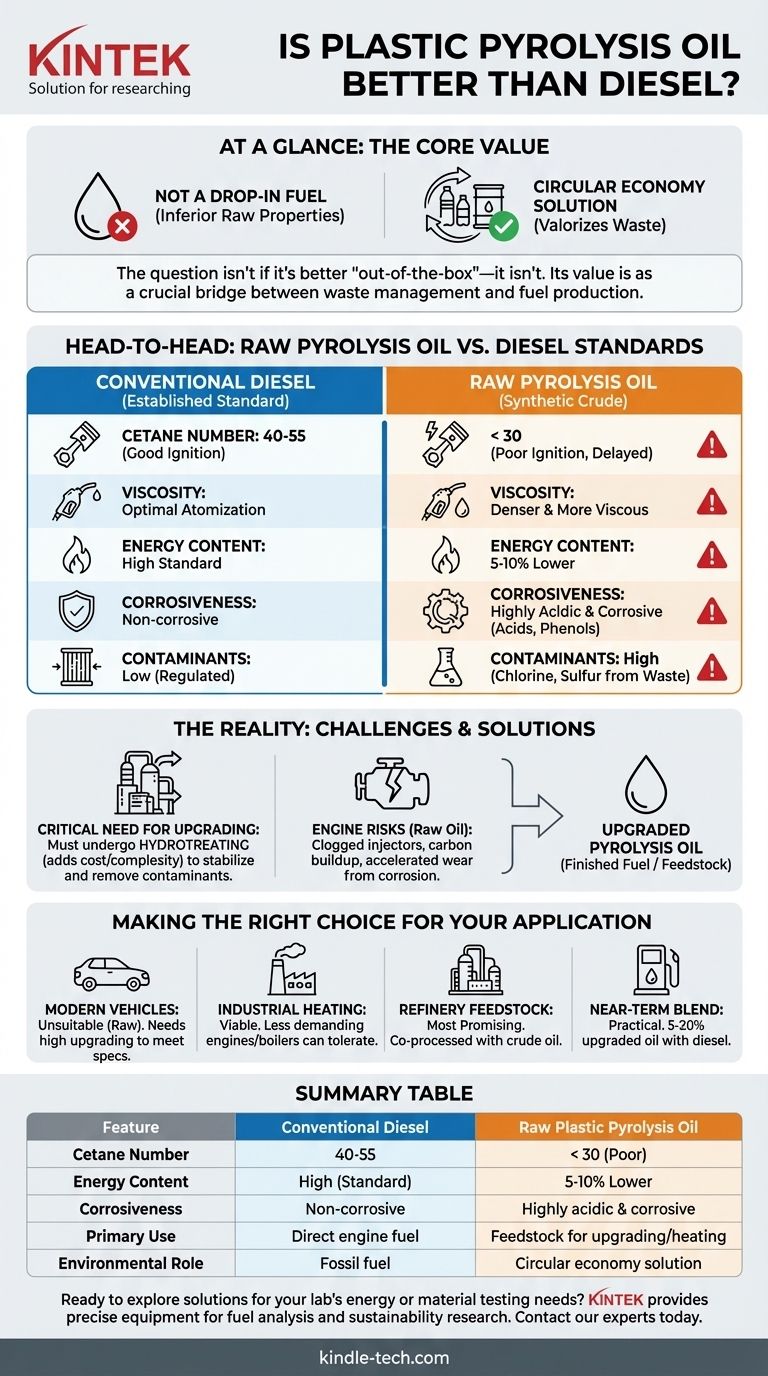

At a glance, plastic pyrolysis oil is not inherently "better" than conventional diesel when judged purely on its performance as a drop-in engine fuel. In its raw form, it has several inferior properties, including lower ignition quality and higher corrosiveness, that prevent it from being a direct substitute. However, its true value lies in its potential as a circular economy solution, turning non-recyclable plastic waste into a valuable energy resource.

The question isn't whether pyrolysis oil is a better fuel out-of-the-box—it isn't. The real consideration is its role in the broader energy and waste ecosystem, where it serves as a crucial bridge between plastic waste management and liquid fuel production.

What is Plastic Pyrolysis Oil?

To compare it to diesel, we first must understand what it is and how it's made. This context is key to understanding its strengths and weaknesses.

The Pyrolysis Process Explained

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-starved environment.

Essentially, mixed plastic waste is shredded and heated to 400-600°C (750-1100°F) without air. This process breaks down the long polymer chains of the plastic into smaller, volatile hydrocarbon molecules, which are then condensed into a liquid known as pyrolysis oil.

The Goal: Turning Waste into a Resource

The primary driver for pyrolysis is not to create a superior fuel, but to valorize waste.

It offers a chemical recycling pathway for low-grade, mixed, and contaminated plastics that are otherwise destined for landfills or incineration. This transforms a significant environmental problem into a potential domestic energy source.

A Head-to-Head Comparison: Pyrolysis Oil vs. Diesel

When evaluated against established diesel fuel standards (like ASTM D975 or EN 590), raw pyrolysis oil falls short in several critical areas.

Cetane Number (Ignition Quality)

The cetane number measures how readily a fuel ignites under compression. Diesel engines rely on high-compression ignition, making this a vital parameter.

- Diesel: Standard diesel fuel has a cetane number between 40 and 55.

- Pyrolysis Oil: Raw pyrolysis oil often has a very low cetane number, sometimes below 30. This leads to delayed ignition, rough engine operation, and incomplete combustion.

Viscosity and Density

Viscosity affects how well the fuel atomizes when sprayed by an injector.

Pyrolysis oil is generally denser and more viscous than diesel. This can strain fuel pumps and lead to poor atomization, resulting in larger fuel droplets that don't burn efficiently.

Calorific Value (Energy Content)

Calorific value, or heating value, is the amount of energy released during combustion.

The energy content of pyrolysis oil is typically 5-10% lower than that of conventional diesel. This means more fuel is required to produce the same amount of power.

Acidity and Corrosiveness

This is one of the most significant technical barriers.

Plastics like PET and impurities in the feedstock can introduce oxygen into the oil, creating carboxylic acids and phenols. This makes the oil acidic and highly corrosive to standard fuel lines, pumps, and engine components. Diesel fuel is non-corrosive.

Sulfur and Chlorine Content

Contaminants in the plastic waste directly translate into contaminants in the oil.

If the feedstock contains PVC (polyvinyl chloride), the resulting oil will have a high chlorine content. During combustion, this forms hydrochloric acid, which is extremely corrosive. Likewise, any sulfur in the plastic waste will end up in the oil, contributing to sulfur oxide (SOx) emissions.

Understanding the Trade-offs: The Reality of Using Pyrolysis Oil

The comparison above makes it clear that using raw pyrolysis oil directly is not feasible. Its practical application involves significant challenges and further processing.

The Critical Need for Upgrading

Raw pyrolysis oil is best viewed as a synthetic crude oil, not a finished fuel. To be usable in a modern diesel engine, it must undergo extensive upgrading, primarily through a process called hydrotreating.

Hydrotreating uses hydrogen, high pressure, and a catalyst to stabilize the fuel and remove contaminants. It increases the cetane number, reduces acidity, and removes sulfur, chlorine, and nitrogen. This process adds significant cost and complexity.

Engine Performance and Durability Risks

Using raw or improperly upgraded pyrolysis oil can cause severe engine problems. These include clogged fuel injectors, carbon buildup on pistons and valves, and accelerated wear of engine components due to corrosiveness.

The Environmental Equation

The primary advantage of pyrolysis oil is environmental: it diverts plastic waste from landfills and oceans.

However, the process is not emission-free. Pyrolysis requires an energy input, and burning the final fuel still produces CO2 and other pollutants like NOx. The overall benefit depends heavily on the efficiency of the plant and the type of waste being processed.

Making the Right Choice for Your Application

The "best" use for plastic pyrolysis oil depends entirely on the end goal. It is not a one-size-fits-all solution.

- If your primary focus is a drop-in fuel for modern vehicles: Unrefined pyrolysis oil is unsuitable. You must use a highly upgraded and refined version that meets all standard diesel specifications.

- If your primary focus is stationary power or industrial heating: Less demanding engines, boilers, or furnaces can often tolerate lower-quality fuels, making unrefined or minimally processed pyrolysis oil a more viable option for heat and power generation.

- If your primary focus is large-scale sustainability: The most promising pathway is using pyrolysis oil as a feedstock for existing oil refineries. Here, it can be blended with conventional crude oil and co-processed into standard gasoline, diesel, and other products, leveraging massive existing infrastructure.

- If your primary focus is a near-term diesel alternative: Blending a small percentage (5-20%) of upgraded pyrolysis oil with conventional diesel is a practical approach that reduces fossil fuel consumption while mitigating the risks of using a 100% alternative fuel.

Ultimately, plastic pyrolysis oil is a powerful tool for chemical recycling that creates a synthetic crude oil, not a finished diesel fuel.

Summary Table:

| Feature | Conventional Diesel | Raw Plastic Pyrolysis Oil |

|---|---|---|

| Cetane Number (Ignition) | 40-55 | < 30 (Poor) |

| Energy Content | High (Standard) | 5-10% Lower |

| Corrosiveness | Non-corrosive | Highly acidic & corrosive |

| Primary Use | Direct engine fuel | Feedstock for upgrading or industrial heating |

| Environmental Role | Fossil fuel | Circular economy solution for plastic waste |

Ready to explore solutions for your lab's energy or material testing needs?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed to analyze alternative fuels, test material properties, and advance your sustainability research. Whether you're working with pyrolysis products or developing new energy sources, our expertise can support your projects.

Contact our experts today to discuss how we can help you achieve your research and development goals.

Visual Guide

Related Products

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

People Also Ask

- Does nanomaterials have potential hazards to human health? Understanding the Risks and Safe Handling

- What is the cost of biomass production? Unpacking the True 'Delivered Cost' to Your Facility

- What is sintering process related to? Mastering Powder-to-Solid Manufacturing

- What is the significance of a constant temperature drying oven in high-pressure CO2 reduction? Ensure Stable Results

- What is the use of oil sludge? Turn Hazardous Waste into Energy & Construction Materials

- Why is argon gas used during the sputtering of a metal? Achieve High-Quality, Contamination-Free Thin Films

- How can you control temperature inside a resistance furnace? Master Precise Thermal Management

- What are the primary applications of ULT freezers? Essential for Preserving Biological & Chemical Samples