Yes, Physical Vapor Deposition (PVD) coating is considered a fundamentally safe and environmentally sound process. It is a vacuum deposition method that produces a durable, inert coating without creating harmful byproducts, waste, or gases. The safety of PVD extends from its clean manufacturing process to its ability to improve material integrity without causing thermal damage.

The core reason PVD is considered safe is twofold: the application process is environmentally clean, and the resulting coating enhances the underlying material's durability without compromising its structural integrity or recyclability.

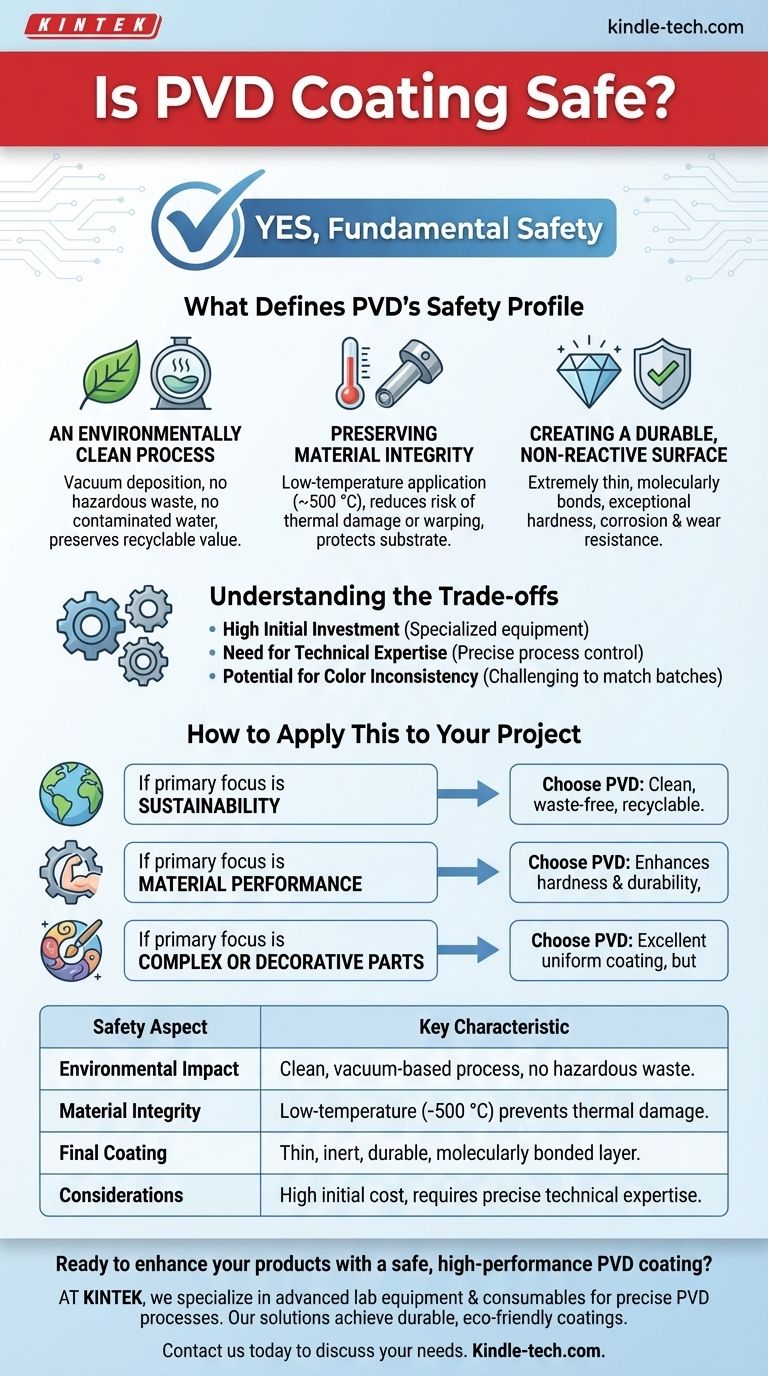

What Defines PVD's Safety Profile

The term "safe" applies to PVD in several distinct contexts: its environmental impact, its effect on the material being coated, and its suitability for consumer products.

An Environmentally Clean Process

PVD is recognized as one of the most environmentally friendly coating processes available. The entire process takes place in a vacuum, which inherently contains the materials used.

Unlike plating processes that rely on wet chemistry, PVD produces no hazardous waste or contaminated water. It also preserves the recyclable value of the substrate, such as stainless steel, ensuring coated products can remain in a sustainable lifecycle.

Preserving Material Integrity

A key advantage of PVD is that it operates at relatively low temperatures (around 500 °C). This is crucial for protecting the object being coated.

This low-temperature application reduces the risk of thermal damage, warping, or other alterations to the substrate's fundamental properties. It makes the process safe for use on materials that might be compromised by higher-temperature methods.

Creating a Durable, Non-Reactive Surface

The resulting PVD coating is extremely thin—often just a few microns—but highly effective. It molecularly bonds to the substrate, creating a surface with exceptional hardness and resistance to corrosion and wear.

This thinness is a form of safety for precision tools, as it preserves the sharpness of a cutting edge while reducing friction and heat during use. For consumer goods like jewelry or fixtures, the inert coating provides a protective barrier.

Understanding the Trade-offs

While PVD is a safe and high-performance process, it comes with specific operational challenges and considerations.

High Initial Investment

The primary drawback of PVD is the requirement for specialized and expensive equipment. The process necessitates a large vacuum chamber and sophisticated controls, representing a significant capital investment.

Need for Technical Expertise

Achieving consistent, high-quality PVD coatings demands a high level of process control and expertise. Factors like temperature, pressure, and deposition rate must be managed precisely.

Potential for Color Inconsistency

While PVD can produce a wide range of decorative finishes, ensuring perfect color consistency across different batches can be challenging. A lack of precise control can lead to off-color results, which may result in material wastage if the parts do not meet specification.

How to Apply This to Your Project

Your decision to use PVD should be guided by your primary objective.

- If your primary focus is sustainability: PVD is a premier choice due to its clean, waste-free process and its ability to preserve the recyclability of the base material.

- If your primary focus is material performance: The low-temperature application enhances hardness and durability without compromising the substrate, making it ideal for high-performance components.

- If your primary focus is complex or decorative parts: PVD offers excellent, uniform coating on various materials, but be prepared to partner with an operator with proven expertise in color and quality control.

Ultimately, PVD coating stands out as a safe and effective method for improving the longevity and performance of a material with minimal environmental impact.

Summary Table:

| Safety Aspect | Key Characteristic |

|---|---|

| Environmental Impact | Clean, vacuum-based process with no hazardous waste or contaminated water. |

| Material Integrity | Low-temperature application (~500 °C) prevents warping or thermal damage. |

| Final Coating | Thin, inert, and durable layer that molecularly bonds to the substrate. |

| Considerations | High initial equipment cost and requires precise technical expertise for consistency. |

Ready to enhance your products with a safe, high-performance PVD coating?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise PVD processes. Our solutions help you achieve durable, environmentally friendly coatings that improve material longevity and performance. Whether you're working on high-performance components or decorative parts, our expertise ensures quality and consistency.

Contact us today to discuss how KINTEK can support your laboratory's coating needs and help you leverage the benefits of PVD technology.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating