In its final, finished state, a PVD coating is considered non-toxic and fundamentally safe. This is because the process creates a stable, inert surface where coating materials are molecularly bonded to the underlying product. This strong bond prevents the material from leaching, flaking, or becoming airborne during everyday use.

The safety of PVD coatings hinges on a critical distinction: while the manufacturing process involves materials that can be hazardous if inhaled, the finished product is safe for end-users due to the incredibly strong, stable bond the coating forms with the surface.

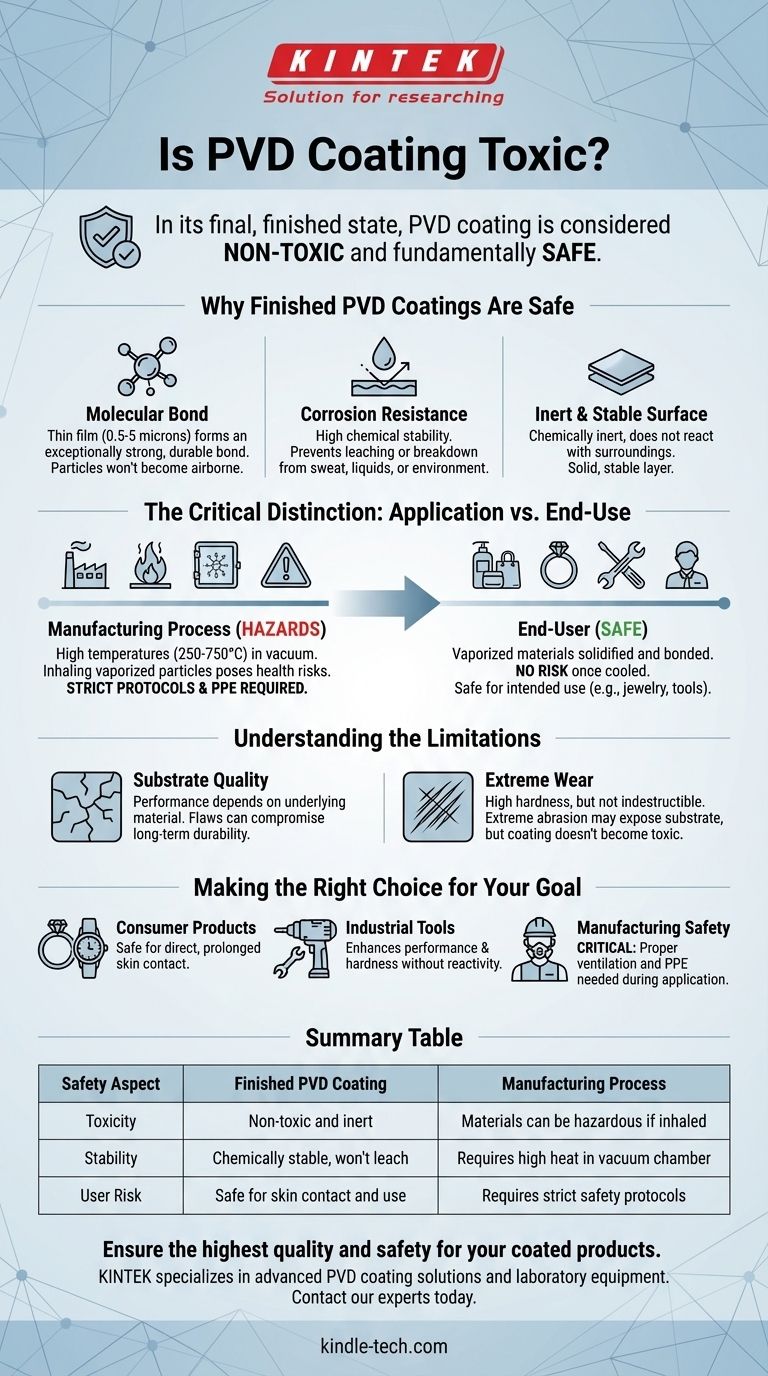

Why Finished PVD Coatings Are Safe

Physical Vapor Deposition (PVD) is an advanced finishing technique that alters a material's properties on a molecular level. The safety of the final product is not an accident but a direct result of how the coating is created and what it does.

The Nature of the Molecular Bond

PVD is a process that deposits a very thin film—often between 0.5 and 5 microns—one molecule at a time in a vacuum. This method creates an exceptionally strong and durable bond between the coating and the substrate material it is applied to.

The particles of the coating are so firmly bonded together that they will not become airborne or separate from the product under normal conditions.

Exceptional Resistance to Corrosion

A key property of PVD coatings is their high resistance to corrosion and oxidation. This chemical stability is crucial for safety.

Because the surface does not easily react with sweat, liquids, or other environmental factors, it prevents the coating from breaking down or leaching materials.

An Inert and Stable Surface

The finished PVD coating is chemically inert, meaning it doesn't react with its surroundings. This is why it's used in applications ranging from architectural fixtures to tools.

This inertness ensures that the surface itself does not pose a risk, as it remains a solid, stable layer.

The Critical Distinction: Application vs. End-Use

Understanding the context of where and when PVD is handled is essential to understanding its safety profile. There is a significant difference between the manufacturing environment and the finished product.

Potential Hazards During Manufacturing

The PVD process must be performed at high temperatures (from 250°C to 750°C) inside a vacuum chamber to vaporize the coating material.

Inhaling these microscopic, airborne particles during the application process can pose health risks. Therefore, strict safety protocols and protective equipment are required for workers in a manufacturing setting.

Safety for the End-User

Once the coating process is complete and the product has cooled, these risks are eliminated entirely. The vaporized materials have solidified and bonded to the product.

The final item that reaches a consumer is completely safe for its intended use, whether that is a piece of jewelry, a kitchen faucet, or a high-performance tool.

Understanding the Limitations

While safe, it's important to recognize the factors that ensure the coating's integrity. The safety and durability of the finish are not absolute and depend on certain conditions.

Coating Quality Depends on the Substrate

The overall performance and stability of a PVD coating are directly influenced by the quality of the underlying material.

If the substrate is flawed or improperly prepared, the coating may not adhere correctly, which could compromise its durability over the long term.

Extreme Wear Can Compromise the Layer

PVD coatings offer exceptionally high hardness and wear resistance, but they are not indestructible.

If the coating is subjected to extreme abrasion and is severely scratched or damaged, the underlying material could become exposed. However, this damages the finish but does not cause the coating itself to become toxic.

Making the Right Choice for Your Goal

Your concern about toxicity should be framed by how you interact with the PVD coating.

- If your primary focus is on consumer products (jewelry, watches, fixtures): You can be confident that PVD-coated items are safe for direct and prolonged skin contact.

- If your primary focus is on industrial tools or components: The benefit is a coating that enhances performance and hardness without introducing chemical reactivity or safety risks during use.

- If your primary focus is on manufacturing safety: It is absolutely critical that proper ventilation and personal protective equipment are used during the PVD application process to mitigate the risk of inhaling particulates.

Ultimately, the PVD process is designed to transform materials into a finished surface that is impressively durable, chemically stable, and safe for the end-user.

Summary Table:

| Safety Aspect | Finished PVD Coating | Manufacturing Process |

|---|---|---|

| Toxicity | Non-toxic and inert | Materials can be hazardous if inhaled |

| Stability | Chemically stable, won't leach | Requires high heat in a vacuum chamber |

| User Risk | Safe for skin contact and use | Requires strict safety protocols for workers |

Ensure the highest quality and safety for your coated products.

KINTEK specializes in providing advanced PVD coating solutions and laboratory equipment. Our expertise ensures durable, non-toxic finishes that meet the highest industry standards for jewelry, tools, and industrial components.

Contact our experts today to discuss how we can support your project with reliable, safe, and high-performance coating solutions.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How difficult is it to grow a diamond? The Immense Challenge of Atomic-Level Precision

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What is the frequency of MPCVD? A Guide to Choosing 2.45 GHz vs. 915 MHz for Your Application

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials

- How does MPCVD work? A Guide to Low-Temperature, High-Quality Film Deposition