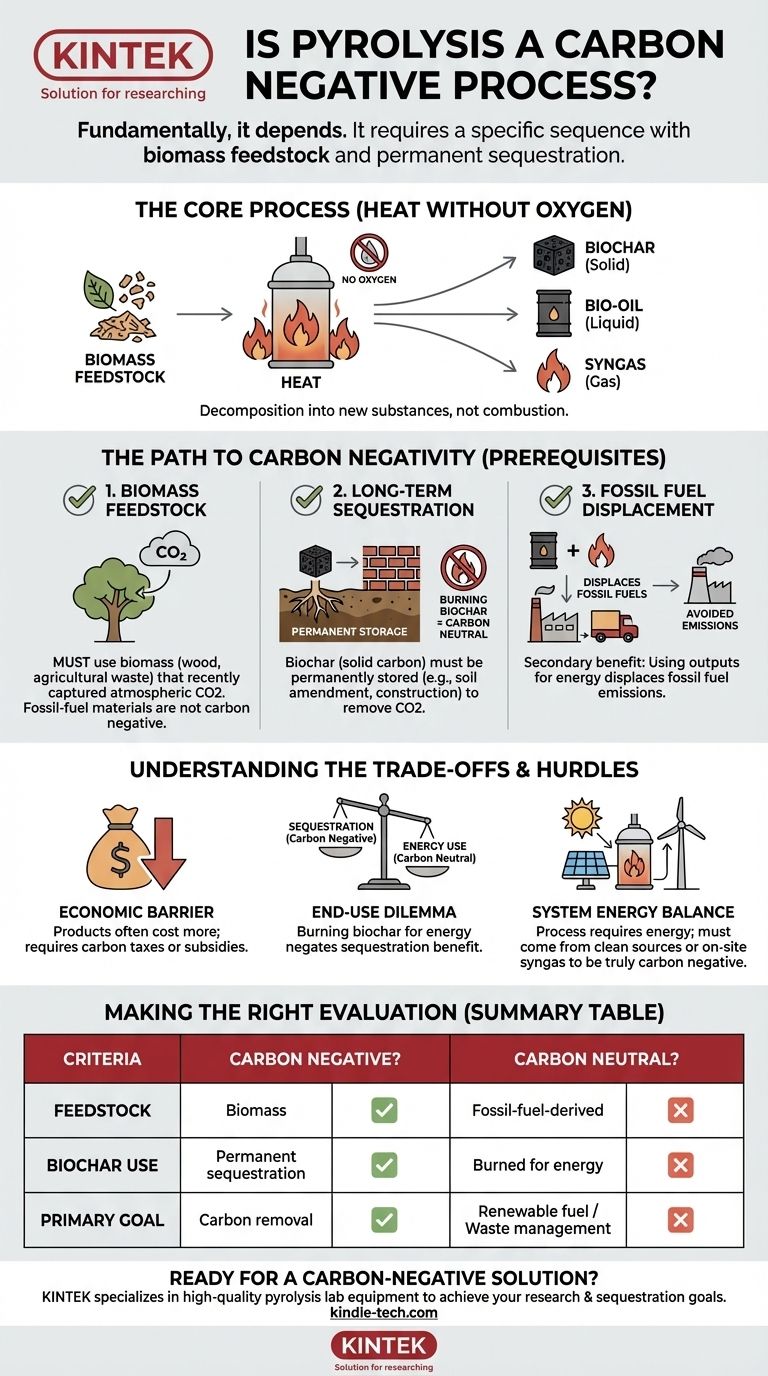

Fundamentally, pyrolysis is not inherently carbon negative. Its ability to remove carbon from the atmosphere depends entirely on two factors: the type of material you put into it and what you do with the products that come out. When biomass is used as a feedstock and its solid carbon byproduct is permanently stored, pyrolysis can be a powerful carbon-negative technology.

The potential for carbon negativity comes from a specific sequence: using biomass (which captured atmospheric CO2) as the input, and then permanently sequestering the resulting stable, solid carbon (biochar) in a way that prevents it from returning to the atmosphere.

How Pyrolysis Works

To understand its carbon footprint, you must first understand the core process. Pyrolysis is a simple, powerful method of thermal decomposition.

The Core Process: Heat Without Oxygen

Pyrolysis involves heating organic materials, such as biomass or plastics, to high temperatures in an environment with little to no oxygen.

Think of it as "cooking" rather than "burning." Because there is no oxygen, the material breaks down into new substances instead of combusting into ash and carbon dioxide.

The Key Outputs: Solids, Liquids, and Gases

This process consistently yields three primary products:

- Biochar (Solid): A stable, carbon-rich material similar to charcoal. The references refer to this as "carbon black," which is one potential form.

- Bio-oil (Liquid): A dense, tar-like liquid that can be refined into transportation fuels or chemicals.

- Syngas (Gas): A mixture of combustible gases (like hydrogen and carbon monoxide) that can be used to generate heat or electricity.

The Path to Carbon Negativity

Achieving carbon negativity with pyrolysis is not automatic; it requires a carefully designed system that meets specific criteria.

Prerequisite 1: Biomass Feedstock

The process can only be carbon negative if the initial feedstock is itself carbon neutral. This means using biomass—such as wood, agricultural waste, or manure.

These materials contain carbon that was recently captured from the atmosphere through photosynthesis. Using fossil-fuel-derived materials like plastic is a form of recycling but cannot be carbon negative, as it re-releases ancient, previously sequestered carbon.

Prerequisite 2: Long-Term Carbon Sequestration

The carbon negativity hinges on what happens to the biochar. To remove CO2 from the atmosphere, this solid carbon must be permanently stored.

If the biochar is used as a soil amendment or mixed into construction materials like bricks, the carbon is effectively sequestered for hundreds or thousands of years.

However, if the biochar is burned as fuel, the captured carbon is simply released back into the atmosphere. This makes the process carbon neutral at best, not carbon negative.

Prerequisite 3: Fossil Fuel Displacement

A secondary carbon benefit comes from using the other outputs—bio-oil and syngas—to replace fossil fuels.

When these pyrolysis-derived fuels are burned to generate energy, they displace the emissions that would have come from burning coal, oil, or natural gas. This creates an avoided emission, further improving the overall carbon balance sheet of the process.

Understanding the Trade-offs and Hurdles

While technically sound, the widespread adoption of pyrolysis for carbon sequestration faces significant practical challenges.

The Economic Barrier

As current analysis shows, the fuels and products from biomass pyrolysis are often more expensive than their fossil-fuel counterparts.

The process typically requires financial incentives like carbon taxes or subsidies to become economically competitive. Without these, there is little market-driven reason to choose pyrolysis over cheaper, conventional methods.

The End-Use Dilemma

A core conflict exists between using the outputs for energy versus sequestration. Biochar is a valuable fuel, and burning it can help power the pyrolysis process itself.

However, choosing to burn the biochar for its energy value completely negates the carbon sequestration benefit. A project must have a clear and unwavering goal: either maximize energy production (carbon neutral) or maximize sequestration (carbon negative).

System Energy Balance

The pyrolysis process itself requires a significant energy input to reach high temperatures. For the system to be truly carbon negative, this energy must either come from a clean source (like solar or wind) or from burning the syngas produced on-site.

If fossil fuels are used to power the pyrolysis reactor, those emissions must be accounted for and can easily erase any carbon sequestration gains.

Making the Right Evaluation for Your Goal

When assessing a pyrolysis project, your evaluation must be tied directly to its primary objective.

- If your primary focus is true carbon negativity: Ensure the plan includes using biomass feedstock and has a verifiable, long-term sequestration pathway for the biochar, such as soil amendment or use in building materials.

- If your primary focus is creating renewable fuel: Acknowledge that this is a valuable goal for displacing fossil fuels, but the process will be carbon neutral at best, not carbon negative, as all the captured carbon is eventually released.

- If your primary focus is waste management: Recognize that pyrolysis is an excellent tool for reducing landfill volume, but its carbon impact is entirely dependent on the feedstock used and the final destination of its outputs.

Therefore, the carbon negativity of pyrolysis is not a property of the technology itself, but a deliberate outcome of a carefully designed and economically supported system.

Summary Table:

| Criteria | Carbon Negative? | Carbon Neutral? |

|---|---|---|

| Feedstock | Biomass (wood, agricultural waste) | Fossil-fuel-derived materials (plastic) |

| Biochar Use | Permanent sequestration (soil, construction) | Burned for energy |

| Primary Goal | Carbon removal | Renewable fuel production / Waste management |

Ready to implement a carbon-negative pyrolysis solution in your lab? KINTEK specializes in high-quality lab equipment and consumables, providing the reliable pyrolysis reactors and systems you need to effectively process biomass and achieve your carbon sequestration goals. Contact our experts today to discuss how our solutions can support your research and sustainability initiatives.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas