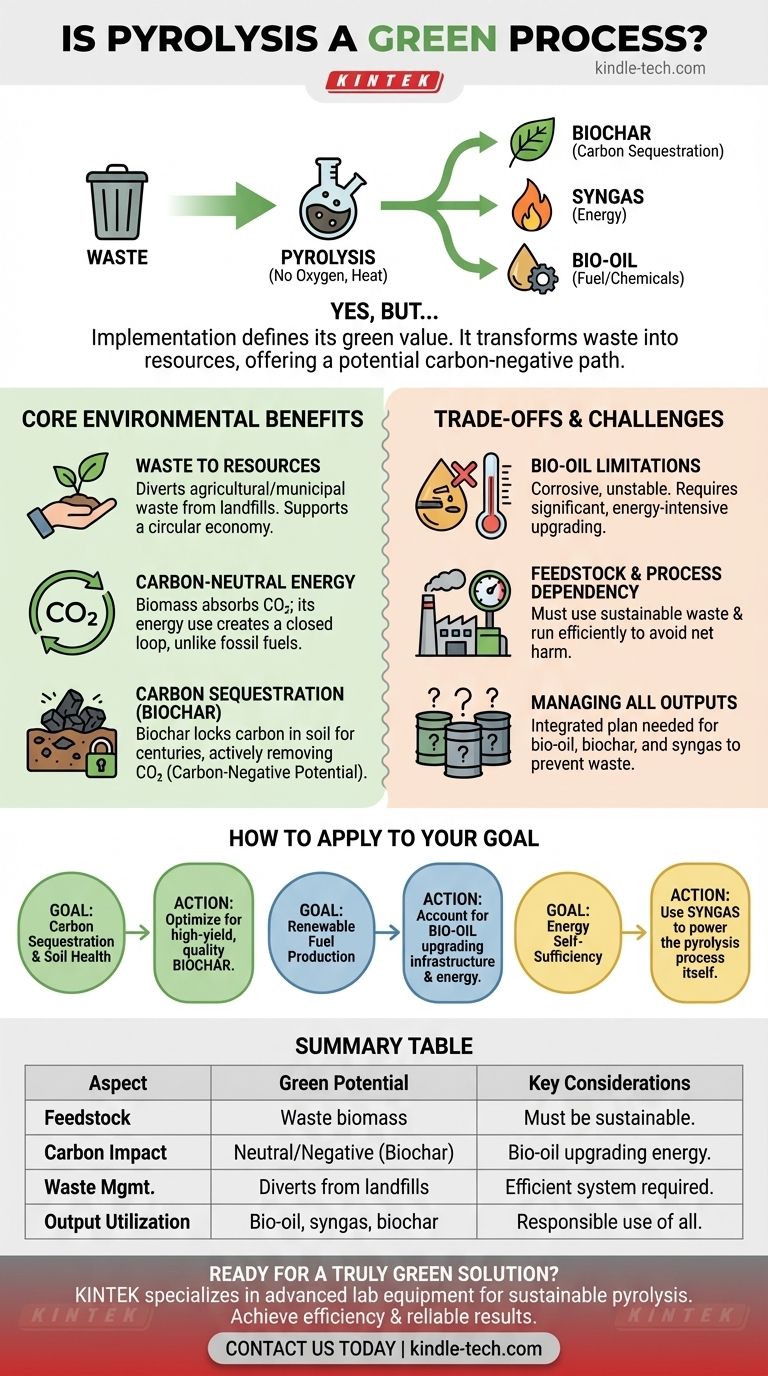

Yes, pyrolysis is broadly considered a green process, but this classification depends heavily on the specifics of its application. At its best, pyrolysis transforms low-value waste into renewable energy and stable biochar, offering a carbon-neutral or even carbon-negative pathway. It reduces reliance on fossil fuels and provides a sustainable method for managing agricultural, wood, and municipal solid waste.

The environmental value of pyrolysis is not inherent in the technology itself, but in how it is implemented. Its "green" credentials hinge on using sustainable feedstock, operating an efficient system, and ensuring all its outputs—bio-oil, biochar, and syngas—are utilized in an environmentally responsible manner.

The Core Environmental Benefits of Pyrolysis

Pyrolysis is an attractive technology because it addresses several environmental challenges simultaneously. It operates by heating organic materials, such as biomass, in the absence of oxygen, which prevents combustion and instead breaks them down into valuable products.

Transforming Waste into Resources

Pyrolysis provides a powerful opportunity to process materials that would otherwise end up in landfills. It can effectively handle agricultural residues, wood processing waste, and even certain components of municipal solid waste.

This turns a disposal problem into a resource production opportunity, aligning with the principles of a circular economy.

Creating a Carbon-Neutral Energy Cycle

The biomass used in pyrolysis, such as plants and wood, absorbs carbon dioxide from the atmosphere as it grows. When the fuel produced from this biomass is used for energy, it releases that same CO2.

This creates a closed loop, in contrast to fossil fuels, which release ancient, sequestered carbon into the atmosphere, leading to a net increase in greenhouse gases.

The Power of Carbon Sequestration via Biochar

One of the most significant environmental benefits of pyrolysis is the production of biochar, a stable, carbon-rich solid.

When this biochar is incorporated into soil, the carbon it contains is locked away for hundreds or even thousands of years. This process, known as carbon sequestration, actively removes carbon dioxide from the atmosphere, making pyrolysis a potentially carbon-negative technology.

Understanding the Trade-offs and Challenges

While the potential is significant, labeling pyrolysis as universally "green" is an oversimplification. The reality is more nuanced, with several critical challenges that must be addressed.

The Problem with Pyrolysis Oil (Bio-oil)

The liquid fuel produced by pyrolysis, known as bio-oil, is not a direct replacement for petroleum products.

Due to its high oxygen content, bio-oil is corrosive, thermally unstable, and does not mix with conventional fossil fuels. It often requires significant and energy-intensive upgrading before it can be used in standard engines or refineries, which can offset some of its environmental benefits.

Dependency on Feedstock and Process

The sustainability of pyrolysis is entirely dependent on its inputs and operational efficiency. The process is only truly renewable if it utilizes genuine waste materials or sustainably harvested biomass.

Furthermore, the pyrolysis unit itself must be highly efficient. A poorly designed or operated system can have its own energy demands and may release harmful pollutants, negating the intended positive impact.

Managing All System Outputs

A truly green pyrolysis operation must have a plan for all three of its primary outputs: bio-oil, biochar, and syngas.

If the syngas is simply flared (burned off) instead of being used to power the process, energy is wasted. If there is no market for the biochar and it is discarded, the carbon sequestration benefit is lost. An integrated approach is essential.

How to Apply This to Your Goal

To determine if pyrolysis is the right "green" solution, you must first define your primary environmental objective.

- If your primary focus is carbon sequestration and soil health: Optimize your process for high-yield, high-quality biochar production for use in agriculture.

- If your primary focus is renewable fuel production: You must account for the necessary infrastructure and energy costs associated with upgrading the unstable bio-oil into a usable fuel.

- If your primary focus is energy self-sufficiency and waste reduction: Choose an integrated system where the syngas produced is used to power the pyrolysis process itself, maximizing overall efficiency.

Ultimately, pyrolysis is not an automatic solution, but a powerful tool that, when engineered and applied thoughtfully, can play a vital role in building a more sustainable, circular economy.

Summary Table:

| Aspect | Green Potential | Key Considerations |

|---|---|---|

| Feedstock | Uses waste biomass (agricultural/wood residues) | Must be sustainable to avoid ecosystem harm |

| Carbon Impact | Carbon-neutral or negative via biochar sequestration | Bio-oil may need energy-intensive upgrading |

| Waste Management | Diverts waste from landfills; supports circular economy | Requires efficient system design to prevent pollution |

| Output Utilization | Produces bio-oil, syngas, and biochar as resources | All outputs must be responsibly used to maximize benefits |

Ready to implement a truly green pyrolysis solution for your laboratory or facility?

At KINTEK, we specialize in advanced lab equipment and consumables tailored for sustainable processes like pyrolysis. Our expertise ensures you achieve optimal efficiency, reliable biochar production, and seamless integration of waste-to-energy systems.

Contact us today to explore how our solutions can help you meet your environmental goals—Get in touch now!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- Why are high temperatures required when sintering stainless steels? Unlock Pure, High-Density Results

- How is a high-temperature calcination furnace utilized in BZY20 Sol-gel? Achieve Pure Cubic Perovskite Phases

- At what temperature is conventional pyrolysis done? Unlock the Right Temperature for Your Desired Product