In principle, yes. Pyrolysis is a powerful thermochemical process that can be a green technology by converting waste biomass and other organic materials into renewable energy and stable carbon. However, its true environmental credentials are not automatic; they depend entirely on the specific feedstock used, the efficiency of the process, and how the end products are utilized.

Pyrolysis presents a significant opportunity to create value from waste and sequester carbon. Its classification as a "green" technology is conditional, hinging on whether the environmental benefits of its outputs—primarily biochar and bio-oil—outweigh the energy costs and challenges associated with producing and upgrading them.

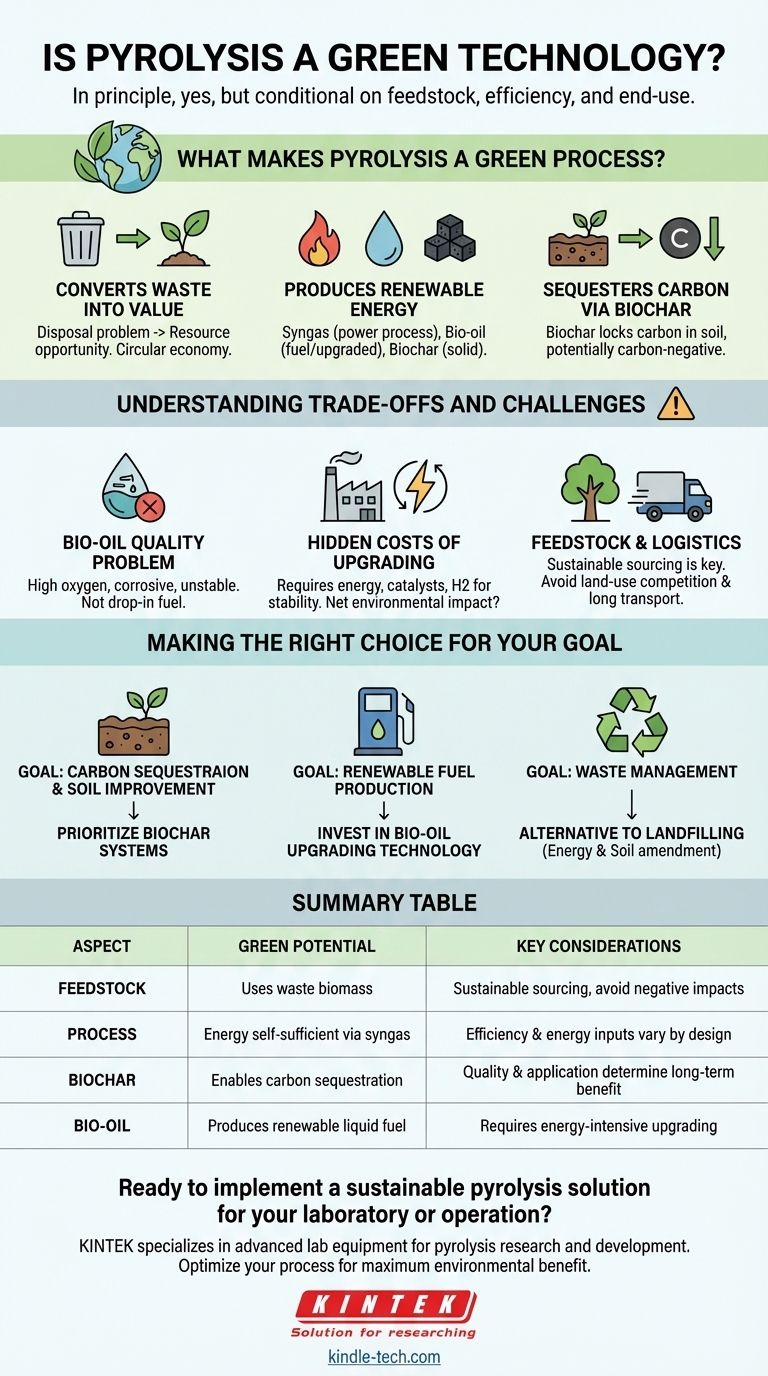

What Makes Pyrolysis a 'Green' Process?

Pyrolysis offers several clear environmental advantages when implemented correctly. The process involves heating organic materials like wood waste, agricultural residue, or municipal solid waste in the absence of oxygen.

It Converts Waste into Value

Pyrolysis provides a productive pathway for materials that might otherwise end up in a landfill, decompose, and release methane. It can process agricultural residues, wood processing waste, and even certain components of municipal solid waste.

This turns a disposal problem into a resource opportunity, aligning with the principles of a circular economy.

It Produces Renewable Energy

The process generates several outputs, including bio-oil (a liquid fuel), syngas (a combustible gas), and biochar (a solid, charcoal-like substance).

The syngas can be used to power the pyrolysis process itself, making the operation self-sustaining. The bio-oil can be used as a fuel for boilers or upgraded into higher-quality liquid fuels.

It Sequesters Carbon via Biochar

Biochar is a stable, carbon-rich solid that resists decomposition for hundreds or even thousands of years.

When biochar is added to soil, the carbon it contains is effectively locked away, preventing it from entering the atmosphere as CO2. This makes pyrolysis a potential carbon-negative technology, where the process removes more carbon from the atmosphere than it emits.

Understanding the Trade-offs and Challenges

The "green" label for pyrolysis is not guaranteed. Objective analysis requires acknowledging the significant technical and operational hurdles that can impact its overall environmental footprint.

The Problem with Bio-Oil Quality

The primary liquid product, bio-oil, is fundamentally different from conventional petroleum fuels. It has a high oxygen content, which makes it corrosive, thermally unstable, and immiscible with fossil fuels.

This means it cannot be used as a "drop-in" fuel for standard engines or easily blended with gasoline or diesel without significant, energy-intensive upgrading.

The Hidden Costs of Upgrading

To become a viable transportation fuel, bio-oil must undergo further processing to remove oxygen and improve its stability. This upgrading process requires energy, catalysts, and hydrogen, all of which have their own associated costs and environmental impacts.

A full lifecycle assessment must account for the energy and emissions from this mandatory upgrading step to determine the net environmental benefit.

Feedstock Sourcing and Logistics

The sustainability of pyrolysis is directly tied to its feedstock. Using genuine agricultural or industrial waste is ideal.

However, if demand leads to the harvesting of dedicated energy crops or unsustainable logging, it could create negative consequences like land-use competition, deforestation, and biodiversity loss. Transporting bulky biomass over long distances can also erode the net energy benefit.

Making the Right Choice for Your Goal

Pyrolysis is not a single solution but a flexible platform. Its environmental value depends on your primary objective.

- If your primary focus is carbon sequestration and soil improvement: Prioritize systems designed for high-quality biochar production, as this is the most direct and stable environmental benefit.

- If your primary focus is renewable fuel production: Acknowledge that creating stable, transport-grade fuel from pyrolysis requires significant downstream investment in bio-oil upgrading technology.

- If your primary focus is waste management: Pyrolysis is an excellent alternative to landfilling for non-recyclable organic waste, converting a liability into energy and a valuable soil amendment.

Ultimately, viewing pyrolysis as a green technology requires a clear-eyed assessment of the entire system, from feedstock to final product.

Summary Table:

| Aspect | Green Potential | Key Considerations |

|---|---|---|

| Feedstock | Uses waste biomass (e.g., agricultural residue) | Sourcing must be sustainable to avoid negative impacts |

| Process | Can be energy self-sufficient via syngas | Efficiency and energy inputs vary by system design |

| Biochar | Enables carbon sequestration in soil | Quality and application determine long-term benefit |

| Bio-oil | Produces renewable liquid fuel | Requires energy-intensive upgrading for transport use |

Ready to implement a sustainable pyrolysis solution for your laboratory or operation?

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether your goal is carbon sequestration, renewable fuel production, or efficient waste management, our technology can help you optimize your process for maximum environmental benefit.

Contact our experts today to discuss how our solutions can support your green technology goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions