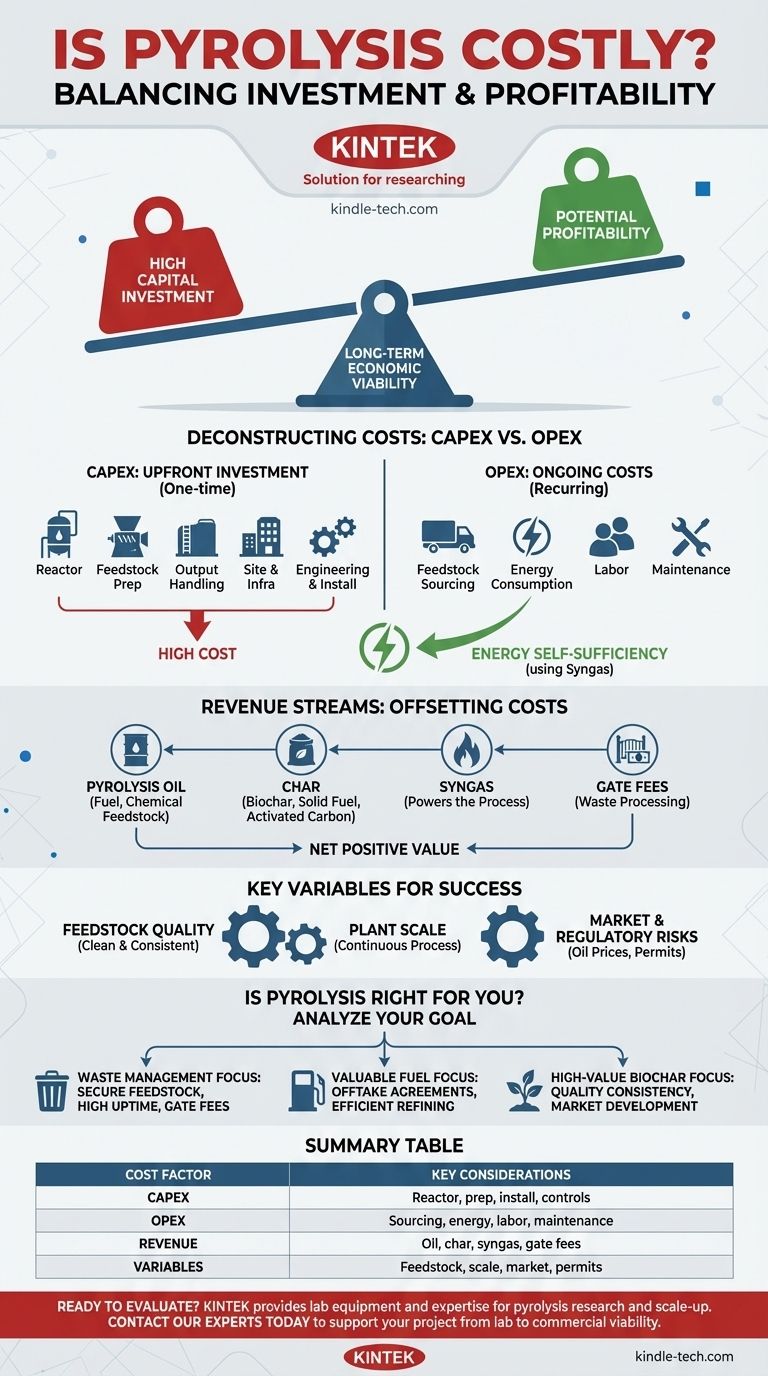

Yes, the initial capital investment for a pyrolysis plant is substantial. However, whether the technology is "costly" over its lifetime is a more complex question. The long-term economic viability hinges on a careful balance of high upfront costs against operational expenses, potential revenue from its products, and any fees collected for processing waste.

The true cost of pyrolysis is not found in its initial price tag, but in the overall profitability equation. A system with a high capital cost can be exceptionally profitable if operational costs are managed and revenue from products like oil, char, and processing fees is maximized.

Deconstructing the Costs: CAPEX vs. OPEX

To accurately assess the cost, you must separate the one-time investment from the recurring operational expenses.

Capital Expenditures (CAPEX): The Upfront Investment

This is the most significant financial hurdle. The primary capital costs include the pyrolysis reactor itself, which varies greatly in price based on its type (e.g., batch vs. continuous) and capacity.

Other major CAPEX components include:

- Feedstock Preparation Equipment: Shredders, dryers, and sorting systems to ensure the material is suitable for the reactor.

- Output Handling Systems: Condensers to capture the oil, storage tanks, and equipment to process the solid char.

- Site and Infrastructure: The cost of land, foundation work, buildings, and utility connections.

- Engineering and Installation: Fees for design, project management, and commissioning the plant.

- Environmental Controls: Gas scrubbers and wastewater treatment systems required for permitting.

Operational Expenditures (OPEX): The Ongoing Costs

These are the recurring costs required to run the plant day-to-day. They have a direct impact on profitability.

Key OPEX factors include:

- Feedstock Sourcing: While waste plastic or biomass may seem "free," the costs of collection, transportation, and pre-sorting can be significant.

- Energy Consumption: Pyrolysis requires heat. A critical factor for economic success is the ability to use the non-condensable syngas produced during the process to power the reactor, dramatically reducing external energy needs.

- Labor: Plants require skilled operators for monitoring, control, and routine tasks.

- Maintenance: Reactors operate under high temperatures and require regular maintenance, repairs, and replacement of parts to ensure reliability.

The Other Side of the Ledger: Potential Revenue Streams

The "cost" of pyrolysis is offset by the value it creates. A successful business model depends on maximizing these revenue streams.

Selling the Primary Products: Pyrolysis Oil and Char

The value of pyrolysis oil is often benchmarked against crude oil prices, but its specific quality (viscosity, purity, energy content) determines its final market price. It may be sold as a fuel for industrial boilers or require further refining to be used as a chemical feedstock.

Char, a solid carbon-rich byproduct, can be sold as a soil amendment (biochar), a solid fuel, or as a raw material for producing activated carbon. The market for char is less mature than for oil but is growing.

Capturing Value from Byproducts: Syngas

The non-condensable syngas produced is a low-to-medium heating value fuel. While rarely valuable enough to purify and sell, its true economic contribution is in powering the pyrolysis process itself. A plant that is energy self-sufficient has a massive competitive advantage.

Service-Based Revenue: Gate Fees

For plants designed to process waste (like tires or mixed plastics), a major revenue stream is the gate fee (or tipping fee). This is the fee that municipalities or commercial waste producers pay to have their material taken and processed, turning a potential cost (feedstock) into a source of income.

Understanding the Trade-offs and Key Variables

Judging pyrolysis solely on cost is a common mistake. Success is contingent on managing several critical variables.

Feedstock Quality and Consistency

The type and consistency of your feedstock are paramount. A clean, uniform feedstock (e.g., a single type of plastic) will produce a consistent, higher-value output. Mixed, contaminated waste can cause operational problems and yield lower-quality, less valuable products.

The Critical Role of Scale

The economics of pyrolysis are highly dependent on scale. Small, lab-scale systems are useful for research but rarely profitable. Commercial viability typically requires a continuous-process plant capable of handling a significant volume of feedstock daily.

Market and Regulatory Risks

The profitability of a plant is exposed to market volatility, particularly fluctuating oil prices which affect the value of the pyrolysis oil. Furthermore, obtaining environmental operating permits can be a lengthy and complex process that introduces significant project risk and delays.

Is Pyrolysis the Right Choice for Your Goal?

To determine if pyrolysis is too costly for you, analyze it against your primary objective.

- If your primary focus is large-scale waste management: The key to profitability is securing a steady stream of feedstock with a positive gate fee and achieving a high operational uptime.

- If your primary focus is producing valuable fuel from a specific waste stream: Your success hinges on the offtake agreement for your oil and the efficiency of your refining or upgrading process.

- If your primary focus is creating high-value biochar for agriculture: Your business model depends less on the oil and more on your ability to produce a consistent, high-quality char and develop a stable market for it.

Ultimately, a successful pyrolysis project is defined not by its initial cost, but by its ability to generate net positive value throughout its operational life.

Summary Table:

| Cost Factor | Key Considerations |

|---|---|

| Capital Expenditure (CAPEX) | Reactor, feedstock prep, installation, environmental controls |

| Operational Expenditure (OPEX) | Feedstock sourcing, energy, labor, maintenance |

| Revenue Streams | Pyrolysis oil, char, syngas (for energy), gate fees |

| Key Variables | Feedstock quality, plant scale, market prices, permits |

Ready to evaluate if pyrolysis is a cost-effective solution for your specific waste stream? KINTEK specializes in providing robust lab equipment and consumables for pyrolysis research and process development. Our expertise helps you accurately test feedstock, optimize conditions, and scale your operations efficiently. Contact our experts today to discuss how we can support your project from the lab to commercial viability.

Visual Guide

Related Products

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Laboratory Hybrid Tissue Grinding Mill

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- Why is a Teflon-lined high-pressure reactor utilized for ZnS nanopowders? Ensure Purity & Optimized Crystallization

- How do laboratory-scale high-pressure reactors facilitate HTL of mixed plastic waste? Unlock Efficient Recycling

- What is the role of a stainless steel high-pressure reactor in the hydrothermal synthesis of MIL-88B? Boost MOF Quality

- Why are 5 to 10 mL microreactors preferred for hydrothermal synthesis? Master Particle Precision and Scalability

- What is the role of a high-pressure hydrothermal reactor in mushroom substrate HTC? Enhance Biochar Yield & Quality