In principle, yes, but in practice, its environmental friendliness is highly conditional. Plastic pyrolysis is a chemical recycling method that can convert plastic waste into valuable products like oil and gas, offering a clear alternative to landfills. However, its actual environmental impact is not guaranteed and depends entirely on the sophistication of the technology, the quality of the plastic feedstock, and the management of all outputs and emissions.

Plastic pyrolysis is not inherently "green." It is a technology whose environmental credentials are determined by how well the system contains harmful emissions, purifies its outputs, and manages its waste streams. A poorly designed or operated facility can create more problems than it solves.

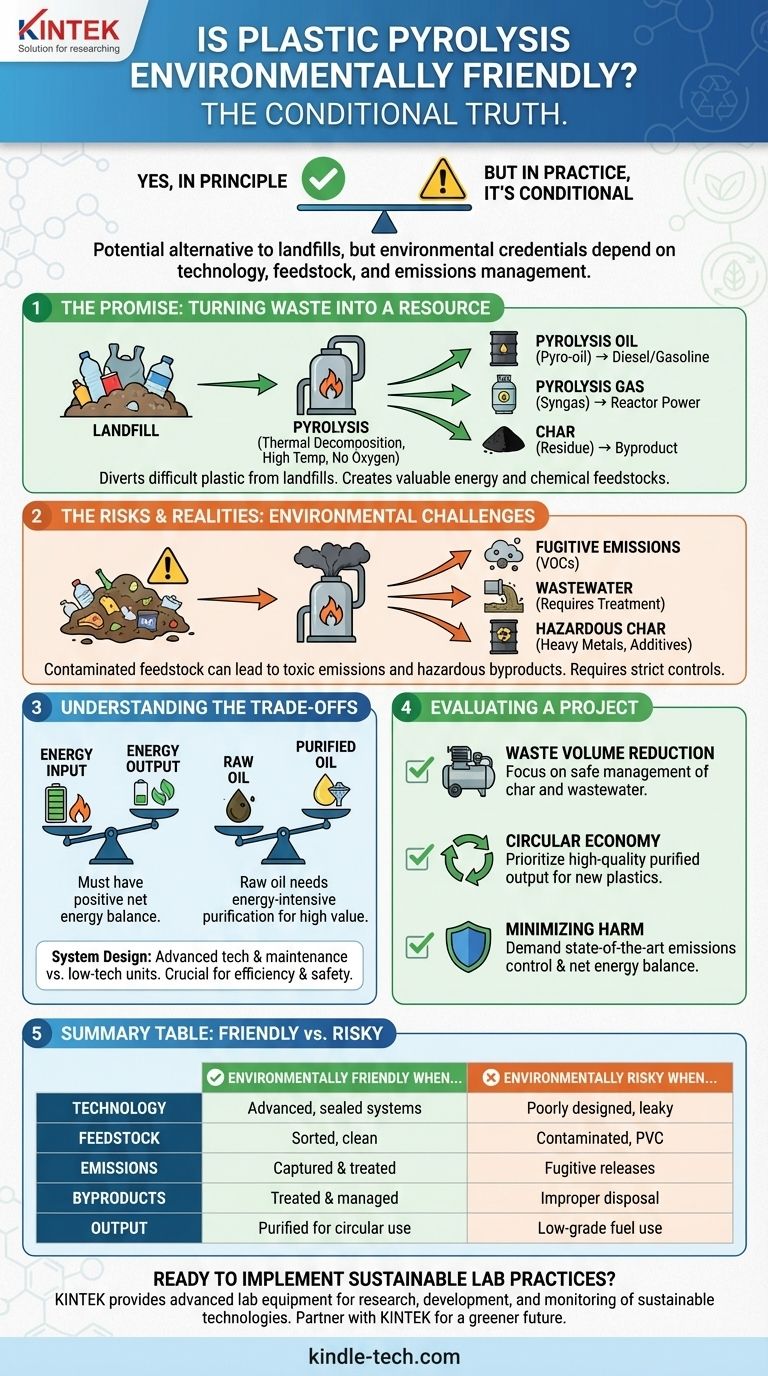

The Promise: Turning Waste into a Resource

Pyrolysis offers a compelling solution to the global plastic waste crisis by chemically decomposing materials that are difficult to recycle mechanically.

The Core Process

Pyrolysis involves heating plastic waste to very high temperatures (typically 300-900°C) in an environment with little to no oxygen. This process, called thermal decomposition, breaks down the long polymer chains of plastics into smaller, simpler molecules.

Valuable Outputs

The primary output is pyrolysis oil (or "pyro-oil"), a synthetic crude oil that can be refined into diesel, gasoline, or other chemical feedstocks. The process also generates pyrolysis gas (syngas), which can be captured and used to power the pyrolysis reactor itself, improving energy efficiency. A solid residue, often a form of carbon black or char, is the final byproduct.

Diverting Waste from Landfills

The most significant and immediate environmental benefit of pyrolysis is its ability to process mixed and contaminated plastic waste that would otherwise be sent to a landfill or incinerator. This directly addresses land and water pollution caused by plastic accumulation.

The Environmental Risks and Realities

The potential benefits of pyrolysis are matched by significant environmental risks that must be managed with advanced engineering and strict operational discipline.

The Problem of Contaminated Feedstock

Real-world plastic waste is rarely clean or homogenous. Contaminants like food residue, paper labels, dirt, and moisture are common. Different plastic types (like PET, HDPE, and PVC) mixed together can also complicate the process.

This variation in feedstock quality directly impacts the quality of the pyrolysis oil and can create more hazardous waste. For example, plastics containing chlorine (like PVC) can form highly toxic dioxins and furans if not processed correctly.

Managing Gaseous Emissions

While pyrolysis occurs in a closed, oxygen-free system, there is always a risk of fugitive emissions. If the system is not properly sealed and maintained, harmful volatile organic compounds (VOCs) and other pollutants can escape into the atmosphere, negatively impacting air quality.

Handling Byproducts: Wastewater and Char

If the incoming plastic waste contains moisture, it will be converted to steam and then condense into wastewater. This water can contain dissolved organic compounds and must be treated before it can be safely discharged.

The solid pyrolysis residue (char) can also be a challenge. It often contains heavy metals, additives, and other contaminants from the original plastic. Disposing of this char must be done responsibly, as it can be classified as hazardous waste.

Understanding the Trade-offs

A successful pyrolysis operation is a balancing act. The environmental friendliness is determined by how well these trade-offs are managed.

Energy Input vs. Energy Output

Pyrolysis is an energy-intensive process. A truly sustainable operation must have a positive net energy balance, meaning it produces more energy than it consumes. The most efficient systems achieve this by using the syngas generated during the process to heat the reactor, reducing reliance on external energy sources.

The Critical Role of Purification

Raw pyrolysis oil is not a drop-in replacement for conventional fuels. It can be acidic, unstable, and contain contaminants. To become a high-value product, it must undergo purification and upgrading, which requires additional energy and resources. Without this step, the oil is often only suitable as a low-grade industrial fuel.

System Design and Operation

There is a vast difference between a state-of-the-art chemical recycling plant and a low-tech, rudimentary pyrolysis unit. Modern, well-engineered systems use advanced sensors, automated controls, and sophisticated gas handling systems to maximize efficiency and minimize pollution. Proper, consistent maintenance is essential to prevent leaks and ensure the process remains safe and clean.

Evaluating a Plastic Pyrolysis Project

To determine if a specific pyrolysis project is environmentally sound, you must look beyond the simple claim of "recycling plastic."

- If your primary focus is waste volume reduction: Pyrolysis is effective at converting bulky plastic into denser outputs, but you must demand a clear and safe management plan for the resulting char and wastewater.

- If your primary focus is creating a circular economy: The key is the quality of the output. The process must include advanced purification to turn pyrolysis oil into a feedstock for new plastics, not just a low-grade fuel.

- If your primary focus is minimizing environmental harm: Prioritize systems with state-of-the-art emissions control, a transparent and positive net energy balance, and a proven ability to handle contaminated, real-world plastic waste.

Ultimately, the environmental merit of plastic pyrolysis is a direct result of the technical rigor and operational discipline applied to the process.

Summary Table:

| Aspect | Environmentally Friendly When... | Environmentally Risky When... |

|---|---|---|

| Technology & Operation | Advanced, sealed systems with strict controls and maintenance are used. | Systems are poorly designed, leaky, or improperly operated. |

| Feedstock Quality | Plastic waste is sorted and relatively clean. | Feedstock is highly contaminated or contains PVC (risk of dioxins). |

| Emissions Management | Harmful gases (VOCs) are captured and treated; syngas is used for energy. | Fugitive emissions are released into the atmosphere. |

| Byproduct Handling | Wastewater is treated; char is responsibly managed or utilized. | Byproducts like char (potentially hazardous) are improperly disposed of. |

| Output Quality | Pyrolysis oil is purified and upgraded for circular use (new plastics). | Oil is used as a low-grade fuel without purification. |

Ready to Implement Sustainable Lab Practices?

Navigating complex processes like pyrolysis requires reliable, high-quality equipment. KINTEK specializes in advanced lab equipment and consumables, providing the precise tools your laboratory needs to research, develop, and monitor sustainable technologies effectively.

Partner with KINTEK to enhance your lab's capabilities and contribute to a greener future. Contact our experts today to find the perfect solutions for your specific challenges!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What role does a laboratory magnetic stirrer play in the acidification pretreatment of aluminum sludge? Speed Recovery

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- What is the role of stirring equipment in the sol-gel coating process? Ensure Perfect Core-Shell Structures

- What are the advantages of RF sputtering over DC sputtering? Achieve Superior Thin Films for Advanced Applications

- What is the thermal conductivity coefficient of graphite? A Guide to Its Anisotropic Properties

- What is the meaning of sintering? A Guide to High-Strength, Complex Part Manufacturing

- Will THC distillate dissolve in water? Unlocking the Science of Water-Soluble Cannabis