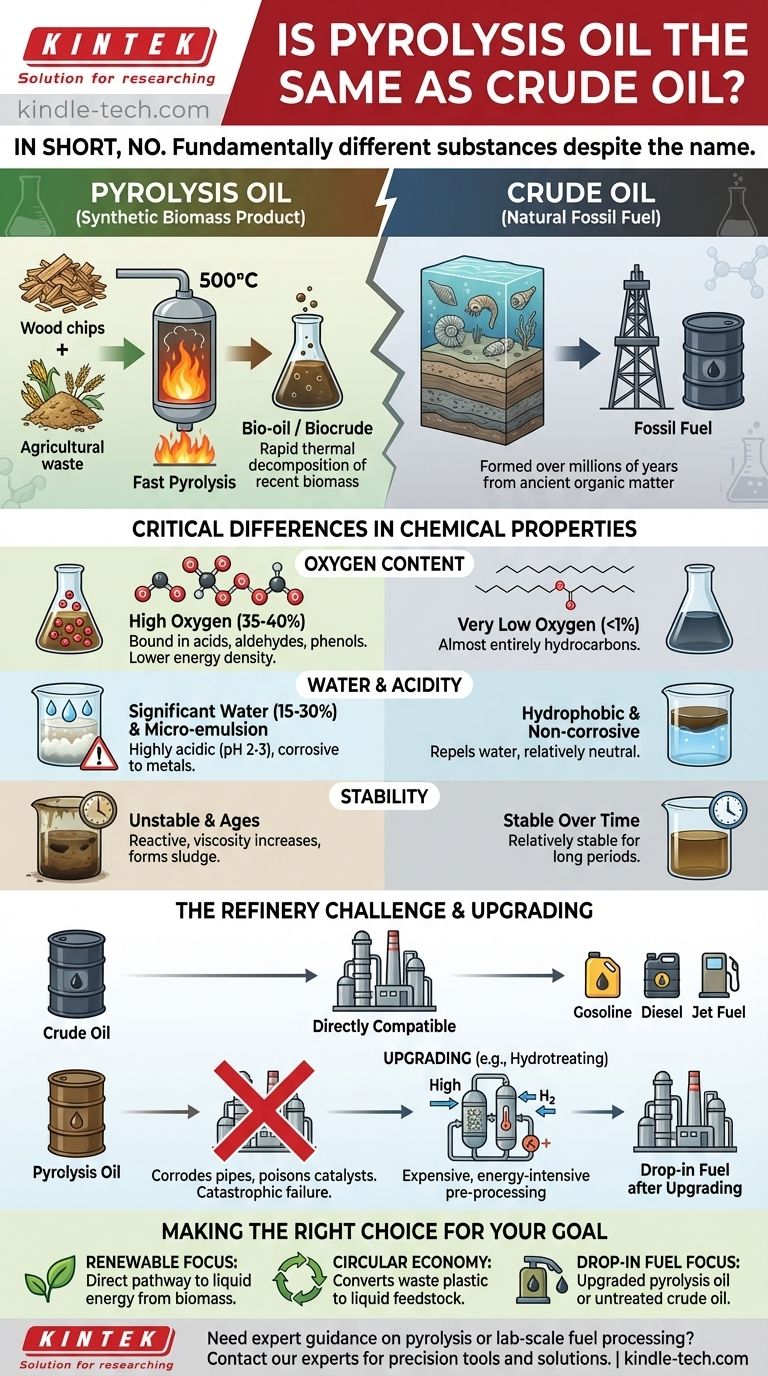

In short, no. Pyrolysis oil and crude oil are fundamentally different substances, despite both being referred to as "oil." Pyrolysis oil is a synthetic liquid fuel derived from the rapid thermal decomposition of recent biomass, like wood or agricultural waste. In contrast, crude oil is a naturally occurring fossil fuel formed over millions of years from ancient organic matter deep within the Earth.

The core distinction lies in their chemical composition. Crude oil is a mixture of hydrocarbons, while pyrolysis oil is a complex, unstable emulsion containing high levels of water and oxygen. This chemical disparity means they cannot be used or refined in the same way.

The Origin Story: Synthetic vs. Natural

Understanding the source of each oil is the first step to grasping their profound differences. They are products of entirely separate processes, timelines, and raw materials.

Crude Oil: A Geological Product

Crude oil is a fossil fuel. It forms from the remains of ancient marine organisms that were buried under layers of sediment millions of years ago.

Intense heat and pressure deep in the Earth's crust transformed this organic matter into a complex mixture of hydrocarbon molecules—chains and rings of hydrogen and carbon atoms. This is the "dinosaur fuel" of popular imagination.

Pyrolysis Oil: A Man-Made Biomass Product

Pyrolysis oil, often called bio-oil or biocrude, is a synthetic product. It is created by a process called fast pyrolysis, where biomass (like wood chips, straw, or other plant matter) is heated to around 500°C in the complete absence of oxygen.

This rapid heating and quenching "freezes" the chemical decomposition process, creating a liquid that has a chemical makeup similar to the original solid biomass. It is not a fossil fuel; it is a way to convert a solid renewable resource into a liquid.

The Critical Differences in Chemical Properties

The different origins result in vastly different chemical and physical properties. These differences are not minor; they dictate how each oil can be stored, transported, and used.

Oxygen Content: The Defining Divide

The most significant chemical difference is oxygen content. Crude oil is almost entirely hydrocarbons, with an oxygen content of less than 1%.

Pyrolysis oil, reflecting its biomass origin, has a very high oxygen content, typically 35-40% by weight. This oxygen is bound within molecules like acids, aldehydes, and phenols, making it a completely different chemical class from crude oil. This high oxygen content also gives it a much lower energy density.

Water and Acidity: The Corrosive Emulsion

Crude oil is largely hydrophobic (it repels water). Pyrolysis oil, however, contains a significant amount of water, often 15-30%.

This water isn't separate; the oil is a micro-emulsion, where organic compounds and water are mixed. It is also highly acidic (pH 2-3) due to the presence of organic acids. As a result, pyrolysis oil is extremely corrosive to common metals like carbon steel, requiring specialized, expensive materials for handling and storage.

Instability and Aging

Crude oil is relatively stable over long periods. Pyrolysis oil is not. The reactive oxygenated compounds within it can continue to react with each other over time, especially when heated.

This process, known as aging or polymerization, causes the oil's viscosity to increase, eventually forming solids and sludge. This instability makes long-term storage and transportation a major technical challenge.

Understanding the Trade-offs: Why You Can't Swap One for the Other

You cannot simply pump pyrolysis oil into the existing infrastructure built for crude oil. Attempting to do so would lead to catastrophic failure.

The Refinery Challenge

A traditional petroleum refinery is engineered to process hydrocarbons. Introducing the high water, oxygen, and acid content of pyrolysis oil would have severe consequences. It would corrode pipes and reactors and instantly poison the expensive catalysts that are essential for refining crude oil into gasoline, diesel, and jet fuel.

The Need for "Upgrading"

For pyrolysis oil to become a "drop-in" fuel compatible with existing refineries, it must first undergo an intensive pre-processing step called upgrading.

This typically involves a high-pressure, high-temperature reaction with hydrogen (hydrotreating) to remove the oxygen and stabilize the molecules. This is an expensive and energy-intensive process that adds significant cost.

Safety and Handling

As a corrosive and hazardous material known to have carcinogenic properties, pyrolysis oil requires specialized handling procedures and personal protective equipment distinct from those used for most crude oils. Its acrid, smoky odor is also a significant operational factor.

Making the Right Choice for Your Goal

Understanding these differences is crucial for evaluating the potential role of each oil in an energy or chemical production strategy.

- If your primary focus is a drop-in fuel for existing infrastructure: Upgraded pyrolysis oil or other biofuels are options, but untreated crude oil is the only feedstock compatible with current global refinery networks without modification.

- If your primary focus is on utilizing renewable resources: Pyrolysis offers a direct pathway to convert solid biomass into a liquid energy carrier, which is easier to transport and store than the original solid feedstock.

- If your primary focus is creating a circular economy: Pyrolysis is a powerful technology for converting non-recyclable plastic waste into a liquid feedstock, which, after upgrading, can be used to produce new plastics.

While both are dark liquids that can be burned for energy, thinking of pyrolysis oil as "synthetic crude" is a misconception; it is a unique chemical product with its own distinct challenges and opportunities.

Summary Table:

| Feature | Pyrolysis Oil | Crude Oil |

|---|---|---|

| Source | Recent biomass (wood, waste) | Ancient fossilized organisms |

| Oxygen Content | 35-40% | <1% |

| Water Content | 15-30% (emulsion) | Negligible |

| Stability | Unstable, ages over time | Stable for long periods |

| Refinery Compatibility | Requires costly upgrading | Directly compatible |

| Primary Use | Renewable fuel, chemical feedstock | Conventional fuel, plastics |

Need expert guidance on pyrolysis or lab-scale fuel processing? KINTEK specializes in laboratory equipment and consumables for energy research, biomass conversion, and chemical analysis. Whether you're upgrading pyrolysis oil, testing biofuels, or developing sustainable processes, our precision tools help you achieve accurate, reliable results. Contact our experts today to find the right solutions for your laboratory's needs.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Customizable CO2 Reduction Flow Cell for NRR ORR and CO2RR Research

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity

- What is the meaning of rotary furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development