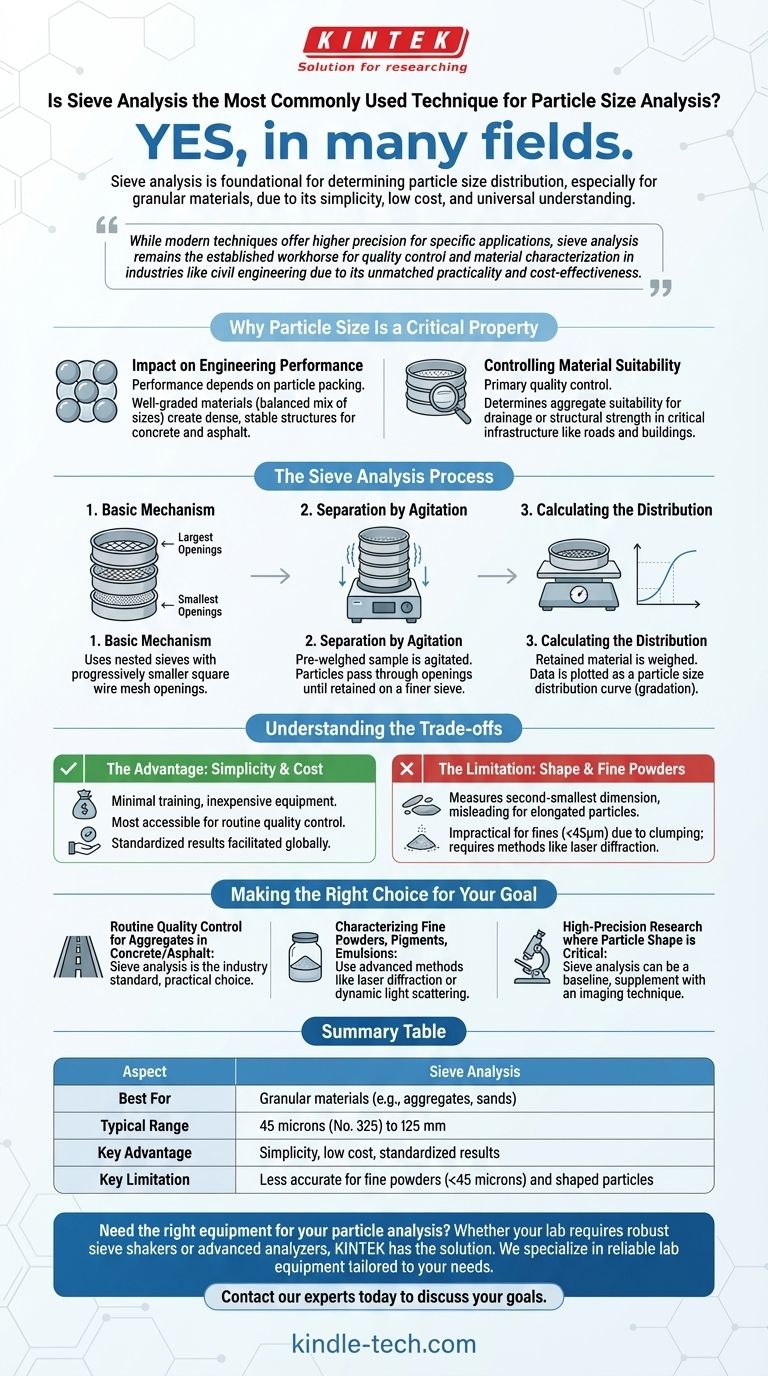

In many fields, yes. Sieve analysis is one of the most common and foundational techniques for determining particle size distribution, especially for granular materials. Its widespread use is a direct result of its simplicity, low cost, and the universal understanding of its methodology and results.

While modern techniques offer higher precision for specific applications, sieve analysis remains the established workhorse for quality control and material characterization in industries like civil engineering due to its unmatched practicality and cost-effectiveness.

Why Particle Size Is a Critical Property

Before evaluating the method, it's crucial to understand why we measure particle size in the first place. The distribution of particle sizes, often called gradation, directly dictates how a material will behave.

The Impact on Engineering Performance

The performance of many materials is a function of how particles of different sizes pack together. A well-graded material has a balanced mix of particle sizes, allowing smaller particles to fill the voids between larger ones.

This creates a dense, stable structure, which is essential for applications like concrete and asphalt mixes.

Controlling Material Suitability

Particle size analysis is a primary quality control step. It determines if an aggregate is suitable for its intended purpose, such as ensuring proper drainage in a filter system or achieving the required strength in a structural concrete beam.

The results from a sieve analysis directly inform the selection of materials for critical infrastructure projects, including roads, buildings, and water wells.

The Sieve Analysis Process

The enduring popularity of sieve analysis comes from its straightforward and intuitive process.

The Basic Mechanism

The method uses a nested stack of sieves, which are wire mesh screens with precisely sized square openings. The sieve with the largest openings is placed on top, with progressively smaller openings in the sieves below it.

Separation by Agitation

A pre-weighed, dry sample of the material is placed in the top sieve. The entire stack is then agitated by a mechanical shaker for a set duration.

This shaking motion allows particles to pass through the sieve openings until they are retained on a sieve that is too fine for them to pass.

Calculating the Distribution

After shaking is complete, the material retained on each sieve is weighed. The weight of the material on each sieve is expressed as a percentage of the total sample weight.

This data is then used to plot a particle size distribution curve, providing a clear visual representation of the material's gradation.

Understanding the Trade-offs

No single technique is perfect for all scenarios. The key is to understand the advantages and limitations of sieve analysis.

The Advantage: Simplicity and Cost

Sieve analysis requires minimal operator training and relatively inexpensive equipment. This makes it the most accessible and cost-effective method for routine quality control in many industries.

Its results are standardized and easily understood across the globe, facilitating clear communication and specification compliance.

The Limitation: Particle Shape

Sieve analysis fundamentally measures a particle's second-smallest dimension, as that is what determines if it can pass through a square opening.

This means that elongated or flat particles may be reported as smaller than they actually are, which can be misleading if particle shape is a critical performance factor.

The Limitation: Fine Powders

The method becomes impractical and less accurate for very fine particles, typically those smaller than about 45 microns (a No. 325 sieve).

For fine powders, cements, or nanomaterials, forces like static electricity and cohesion cause particles to clump together, preventing them from passing through the fine mesh. Other methods, such as laser diffraction, are required for these materials.

Making the Right Choice for Your Goal

Selecting the correct analysis technique depends entirely on your material and your objective.

- If your primary focus is routine quality control for aggregates in concrete or asphalt: Sieve analysis is the industry standard and the most practical and appropriate choice.

- If your primary focus is characterizing fine powders, pigments, or emulsions: You must use a more advanced method like laser diffraction or dynamic light scattering to achieve accurate results.

- If your primary focus is high-precision research where particle shape is a critical variable: Sieve analysis may provide a useful baseline, but it should be supplemented with an imaging technique.

By understanding the core purpose and limitations of each method, you can confidently select the analysis that delivers the necessary accuracy for your project.

Summary Table:

| Aspect | Sieve Analysis |

|---|---|

| Best For | Granular materials (e.g., aggregates, sands) |

| Typical Range | 45 microns (No. 325) to 125 mm |

| Key Advantage | Simplicity, low cost, standardized results |

| Key Limitation | Less accurate for fine powders (<45 microns) and shaped particles |

Need the right equipment for your particle analysis?

Whether your lab requires robust sieve shakers for quality control or advanced analyzers for fine powders, KINTEK has the solution. We specialize in providing reliable lab equipment and consumables tailored to your specific material testing needs.

Contact our experts today to discuss how we can support your laboratory's particle characterization goals and ensure accurate, compliant results.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy