No, sputtering is not a form of Chemical Vapor Deposition (CVD). Sputtering is a cornerstone technique of an entirely different category of thin-film deposition called Physical Vapor Deposition (PVD). The core distinction lies in how the coating material is transferred to the part: PVD uses a physical mechanism, while CVD uses a chemical reaction.

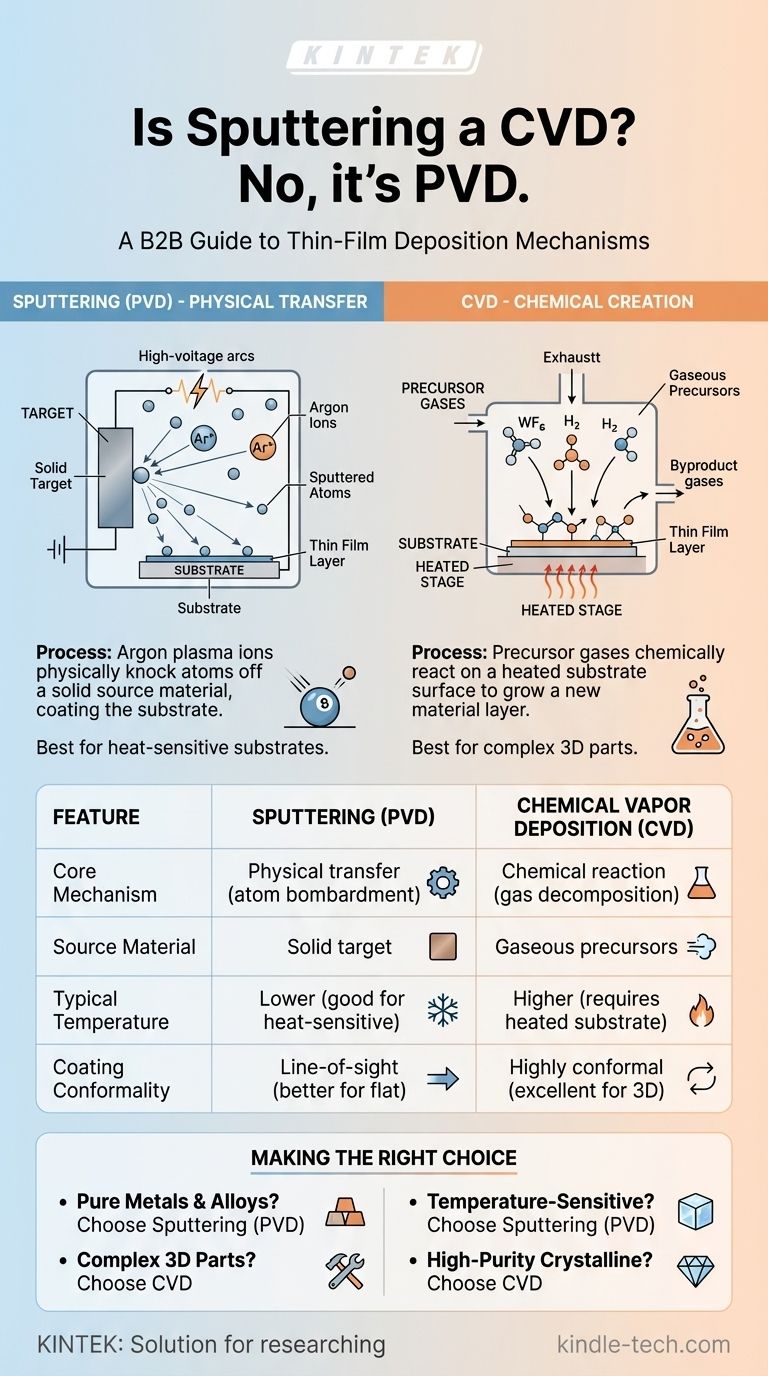

The fundamental difference is this: Sputtering physically knocks atoms off a solid source material, which then coat a substrate. In contrast, CVD uses precursor gases that chemically react on a substrate's surface to grow a new material layer. One is a physical transfer, the other is a chemical creation.

The Core Mechanism: Physical vs. Chemical

To understand why these processes are distinct, we must examine how each one works at a fundamental level. Their goals are similar—to create a thin film—but their methods are opposites.

How Sputtering Works (A Physical Process)

Sputtering is best understood as a microscopic-level billiard ball collision.

The process begins with a solid slab of the desired coating material, known as the target, placed inside a vacuum chamber. An inert gas, typically argon, is introduced into the chamber.

A high voltage is applied, which strips electrons from the argon atoms, creating a glowing, ionized gas called plasma. These positively charged argon ions are then accelerated with immense energy into the negatively charged target.

When these high-energy ions strike the target, they physically dislodge or "sputter" atoms from its surface. These ejected atoms travel through the vacuum chamber and condense onto the substrate, forming a thin, uniform film.

How CVD Works (A Chemical Process)

Chemical Vapor Deposition does not start with a solid target.

Instead, one or more volatile precursor gases containing the required chemical elements are introduced into a reaction chamber. The substrate is heated to a specific temperature that initiates a chemical reaction.

These gases decompose and react on and near the hot substrate surface. The reaction forms a new, solid material that deposits and grows as a film. The byproduct gases are then exhausted from the chamber.

Key Distinctions and Implications

While both processes create high-quality thin films, their underlying differences lead to significant practical trade-offs.

The Source Material

The clearest distinction is the starting state of your coating material. In PVD sputtering, you start with a solid target. If you want to deposit tungsten, you use a solid tungsten target.

In CVD, you start with gaseous precursors. To deposit tungsten, you might use tungsten hexafluoride gas (WF₆) and hydrogen gas (H₂).

Process Conditions

Sputtering is often considered a "cold" process compared to many traditional CVD methods. While the plasma is hot, the substrate can remain near room temperature, making PVD ideal for coating heat-sensitive materials like plastics.

CVD typically requires high temperatures to drive the necessary chemical reactions, which can limit the types of substrates that can be used.

Film Characteristics

Because sputtering is a line-of-sight process, atoms travel in a relatively straight line from the target to the substrate. This makes it excellent for coating flat surfaces but can be challenging for complex, three-dimensional shapes.

CVD, by contrast, is often superior for creating highly conformal coatings. The precursor gases can flow around intricate features, reacting and depositing material evenly on all exposed surfaces.

Making the Right Choice for Your Goal

Understanding the core difference between physical transfer and chemical creation is key to selecting the right technology.

- If your primary focus is depositing pure metals, alloys, or conductive oxides: Sputtering (PVD) is often the most direct, versatile, and cost-effective method.

- If your primary focus is coating a complex 3D part with a uniform, conformal layer: CVD is generally the superior choice due to the nature of gas-phase reactions.

- If your primary focus is coating a temperature-sensitive substrate: Sputtering (PVD) provides a clear advantage by allowing for high-quality films at lower temperatures.

- If your primary focus is creating very specific, high-purity crystalline films: CVD can offer more precise control over film chemistry and atomic structure through careful selection of precursor gases.

Ultimately, sputtering and CVD are distinct but complementary tools in the world of materials science, each defined by its unique deposition mechanism.

Summary Table:

| Feature | Sputtering (PVD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Core Mechanism | Physical transfer (atom bombardment) | Chemical reaction (gas decomposition) |

| Source Material | Solid target | Gaseous precursors |

| Typical Temperature | Lower (good for heat-sensitive substrates) | Higher (requires heated substrate) |

| Coating Conformality | Line-of-sight (better for flat surfaces) | Highly conformal (excellent for 3D parts) |

Need Help Choosing the Right Deposition Technology for Your Application?

Understanding the critical differences between PVD and CVD is the first step to optimizing your thin-film process. KINTEK specializes in providing high-quality lab equipment and consumables for both PVD sputtering and CVD applications. Our experts can help you select the perfect solution to achieve the precise film properties, conformality, and substrate compatibility your project demands.

Contact us today to discuss your specific requirements and discover how KINTEK's solutions can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the advantages of the HFCVD method for preparing diamond films? Faster Growth and Industrial Efficiency

- What is the growth rate of chemical Vapour deposition? It's a Choice Between Speed and Quality

- What is biochar pyrolysis? The Definitive Guide to Slow Pyrolysis for Soil & Carbon Sequestration

- What is the growth process of MOCVD? A Step-by-Step Guide to Epitaxial Thin Film Deposition

- What is chemical vapor deposition in jewelry? Discover the PVD Technology Behind Modern Coatings

- Why are induction coils in induction heating CVD systems typically made of copper tubes and cooled with water?

- What is the MOCVD technique? The Key to Manufacturing High-Performance Semiconductors

- What are the coating methods on carbide inserts? PVD vs. CVD for optimal performance.