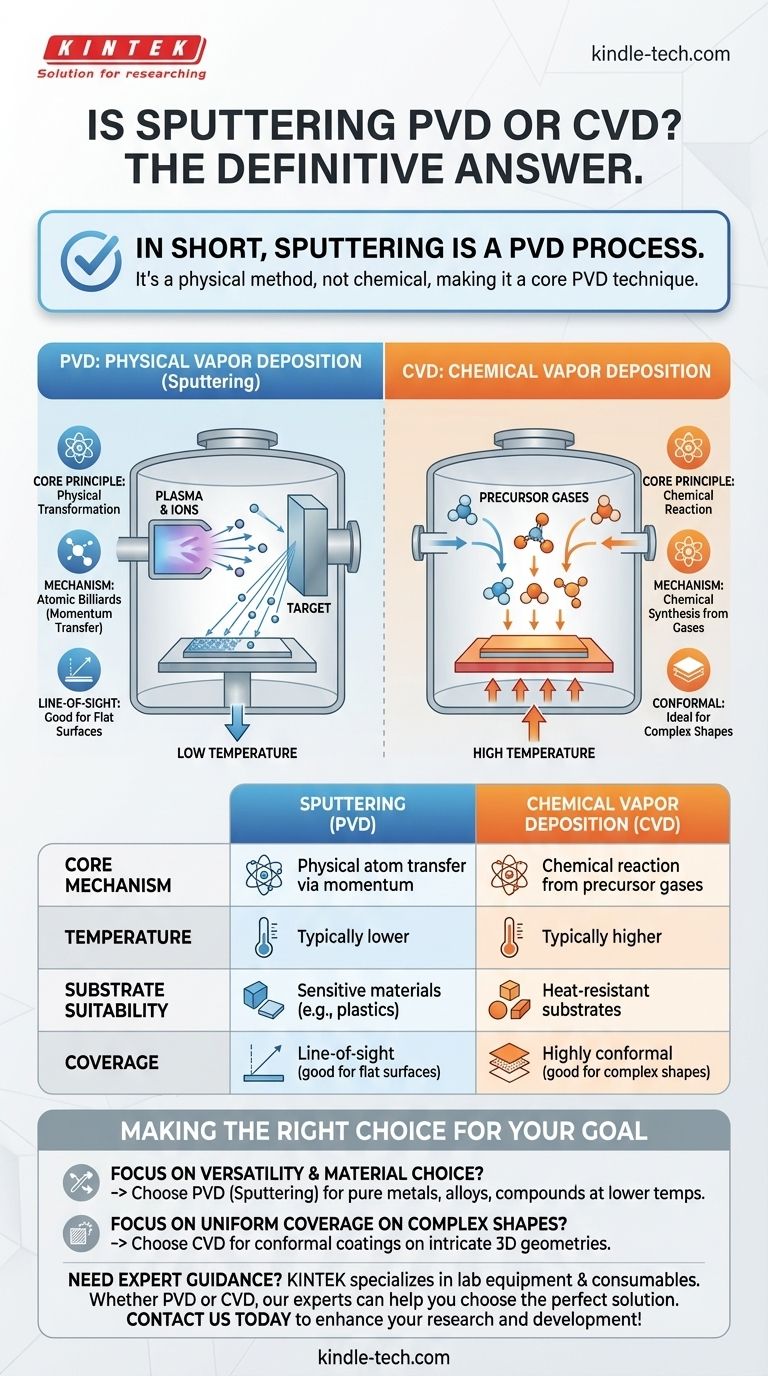

In short, sputtering is a PVD process. It is one of the most common and versatile methods within the Physical Vapor Deposition (PVD) family of techniques. Sputtering is fundamentally a physical mechanism, not a chemical one, which is the defining characteristic that places it firmly in the PVD category and distinguishes it from Chemical Vapor Deposition (CVD).

The core distinction is simple: Physical Vapor Deposition (PVD) physically moves atoms from a solid source to a substrate, like atomic-scale sandblasting. Chemical Vapor Deposition (CVD), in contrast, uses chemical reactions from precursor gases to grow a film on the substrate's surface.

What Defines Physical Vapor Deposition (PVD)?

The Core Principle: Physical Transformation

PVD describes a set of vacuum deposition methods that involve a purely physical transformation. A solid or liquid source material is converted into a vapor phase, transported across a vacuum chamber, and then condensed back into a solid thin film on a substrate.

No fundamental chemical reactions are intended to occur during this process. The deposited film generally has the same chemical composition as the source material.

The "Line-of-Sight" Nature

PVD processes are typically line-of-sight. This means the vaporized atoms travel in a straight path from the source to the substrate.

Imagine using a can of spray paint in a room with no air. The paint particles travel directly from the nozzle to whatever surface they hit first. This is analogous to how PVD coats a substrate, which can make it challenging to evenly coat complex, three-dimensional shapes.

How Sputtering Works as a PVD Process

The Mechanism: Atomic Billiards

Sputtering is a classic example of PVD. The process begins by creating a plasma within a vacuum chamber, usually from an inert gas like argon.

A high voltage is applied to the source material, known as the target. This causes the positively charged argon ions from the plasma to accelerate and bombard the target with immense energy.

When these ions strike the target, they physically knock out, or "sputter," atoms from the target's surface. It is a momentum transfer process, much like one billiard ball striking another.

Condensation into a Film

These ejected atoms travel through the vacuum and condense on the substrate, which is placed nearby. Over time, these atoms build up to form a dense, high-quality thin film.

Because this entire process relies on the physical ejection and redeposition of atoms, it perfectly fits the definition of Physical Vapor Deposition.

Understanding the Trade-offs: PVD vs. CVD

The Defining Difference: Physical vs. Chemical

The critical distinction lies in the deposition mechanism. Sputtering (PVD) uses energetic ions to physically dislodge atoms from a target.

CVD introduces reactive precursor gases into a chamber. These gases decompose and react on the heated substrate's surface, chemically forming a new material as a thin film. It is a process of synthesis, not transfer.

Substrate and Temperature

PVD processes like sputtering can often be performed at lower temperatures than many traditional CVD methods. This makes PVD suitable for coating materials that cannot withstand high heat, such as plastics or certain sensitive electronics.

CVD typically requires high temperatures to drive the necessary chemical reactions on the substrate surface.

Coverage and Conformality

The line-of-sight nature of PVD makes it ideal for coating flat surfaces. However, it can struggle to provide uniform coverage inside deep trenches or on highly complex geometries.

Because CVD relies on gas that can flow around and into features, it generally offers superior conformality. This means it can deposit a film of uniform thickness over intricate, non-planar surfaces.

Making the Right Choice for Your Goal

Understanding this fundamental difference is key to selecting the right technology for your application.

- If your primary focus is versatility and material choice: PVD via sputtering is an excellent choice for depositing a vast range of pure metals, alloys, and compounds onto various substrates, often at lower temperatures.

- If your primary focus is uniform coverage on complex shapes: CVD is often the superior method for creating highly conformal coatings on intricate 3D geometries where line-of-sight deposition would fail.

Ultimately, classifying sputtering as a PVD process is the first step to understanding the unique capabilities and limitations of each deposition technology.

Summary Table:

| Aspect | Sputtering (PVD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Core Mechanism | Physical atom transfer via momentum | Chemical reaction from precursor gases |

| Temperature | Typically lower | Typically higher |

| Substrate Suitability | Sensitive materials (e.g., plastics) | Heat-resistant substrates |

| Coverage | Line-of-sight (good for flat surfaces) | Highly conformal (good for complex shapes) |

Need expert guidance on selecting the right thin-film deposition technology for your lab? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Whether you're working with PVD sputtering systems or CVD reactors, our experts can help you choose the perfect solution for your materials and application. Contact us today to discuss your project and discover how our solutions can enhance your research and development!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition