The primary advantage of a 3-plate mold is its profound gating flexibility, which directly enhances part quality and production efficiency. This design allows for central or multi-point gating on single or multiple parts, a feat often impossible with simpler 2-plate molds, and provides a cost-effective alternative to more complex hot runner systems.

A 3-plate mold is not just a more complex tool; it's a strategic engineering choice. By physically separating the runner system from the part upon ejection, it unlocks superior gating locations that improve plastic flow, part cosmetics, and overall dimensional stability.

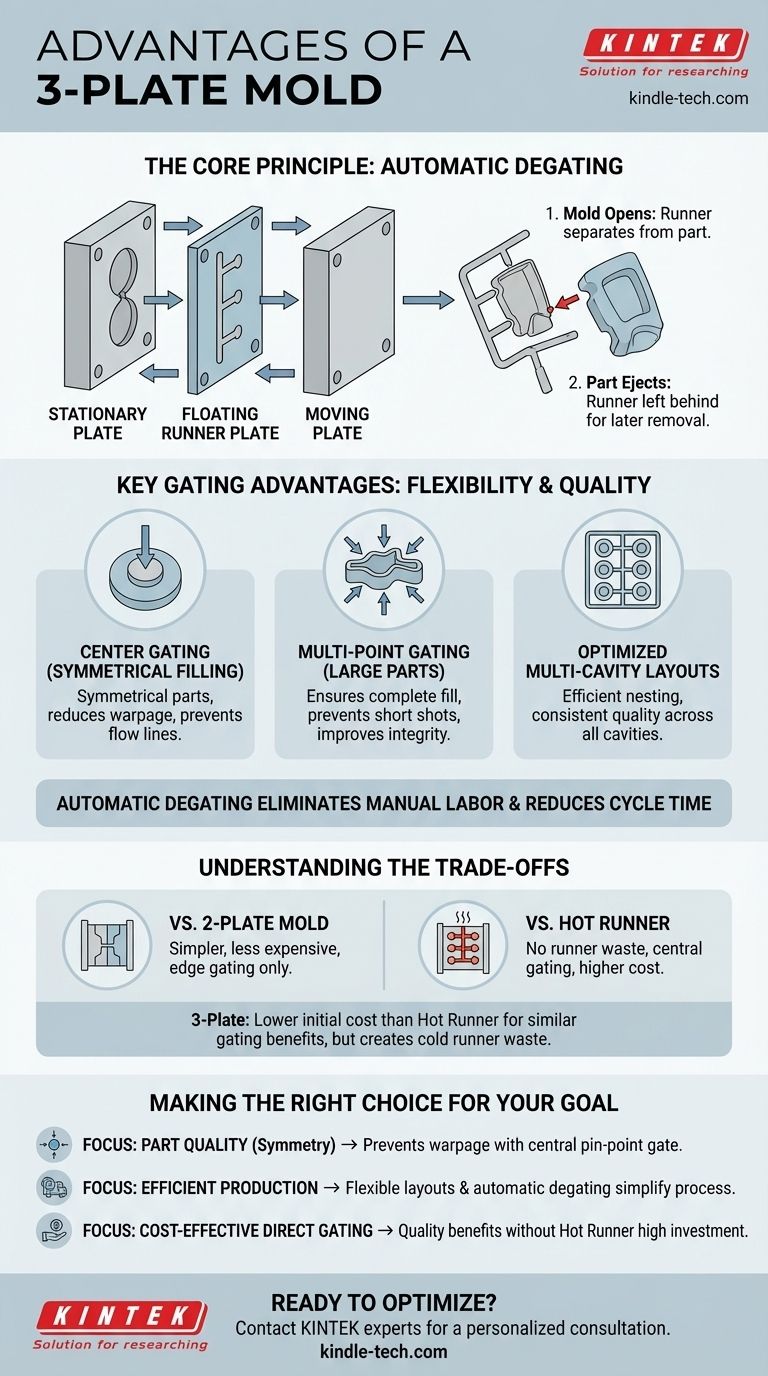

The Core Principle: Automatic Degating

How a 3-Plate Mold Works

Unlike a standard 2-plate mold, a 3-plate mold consists of three distinct sections: the stationary plate, a floating "runner" plate, and the moving plate.

When the mold opens, two parting lines are created. The first parting line separates the runner plate from the stationary plate, breaking the small pin-point gates connected to the part.

The second parting line then opens to eject the finished part, leaving the now-separate runner system behind to be ejected in a subsequent action.

The Benefit of Automatic Separation

This sequential opening process automatically shears the runner from the molded part.

This automation eliminates the need for a secondary manual or robotic operation to remove the runner, reducing labor costs and cycle time.

Key Gating Advantages Explained

Achieving Symmetrical Filling with Center Gating

For round or geometrically balanced parts, the ideal place to inject plastic is directly in the center. This is called a pin-point gate.

A 3-plate mold makes this possible. The runner system exists on a separate plate, allowing a gate to be positioned directly on the top surface of the part.

This central injection point promotes a balanced, uniform flow of material to the part's extremities, drastically reducing the risk of warpage and cosmetic defects like flow lines.

Enabling Multi-Point Gating for Large Parts

Large, complex parts often cannot be filled adequately from a single injection point.

A 3-plate mold design facilitates the use of multiple gates on a single part. This ensures that the molten plastic reaches all areas of the cavity before it solidifies, preventing short shots and improving structural integrity.

Optimizing Multi-Cavity Layouts

When producing multiple parts in one cycle, a 3-plate mold provides superior layout flexibility.

Each cavity can be fed by its own ideal pin-point gate, allowing for dense, efficient nesting of parts while ensuring consistent quality across all cavities.

Understanding the Trade-offs

3-Plate vs. 2-Plate Molds

A 2-plate mold is simpler and less expensive, but it is typically restricted to gating on the part's edge. A 3-plate mold is more complex but unlocks the superior gating options discussed above.

3-Plate vs. Hot Runner Systems

A hot runner system also allows for central gating but keeps the runner material molten, eliminating waste. A 3-plate mold is a cold-runner system, meaning the runner solidifies and is ejected as waste material.

The primary trade-off is cost. A 3-plate mold provides the gating benefits of a hot runner system at a significantly lower initial tooling cost, but at the expense of material waste and potentially longer cycle times.

Increased Complexity and Maintenance

The added plate and mechanisms make a 3-plate mold more complex to design, manufacture, and maintain compared to a 2-plate mold. This complexity can lead to higher upfront costs and a need for more skilled maintenance.

Making the Right Choice for Your Goal

Selecting the correct mold design requires aligning its capabilities with your project's priorities.

- If your primary focus is part quality for a symmetrical part: A 3-plate mold's ability to use a central pin-point gate is often the most effective solution to prevent warpage.

- If your primary focus is efficient production of multiple parts: A 3-plate design allows for flexible cavity layouts and automatic degating, simplifying post-processing and reducing labor.

- If your primary focus is cost-effective direct gating: A 3-plate mold provides the quality benefits of direct part gating without the high initial investment of a hot runner system.

By understanding these core trade-offs, you can select a mold design that is not just functional, but perfectly aligned with your project's quality, budget, and production requirements.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Automatic Degating | Eliminates manual runner removal, reducing labor and cycle time. |

| Center Gating | Enables symmetrical filling for round parts, reducing warpage. |

| Multi-Point Gating | Ideal for large parts, preventing short shots and improving integrity. |

| Cost-Effective Alternative | Provides hot runner gating benefits at a lower initial tooling cost. |

| Optimized Multi-Cavity Layouts | Allows dense nesting of parts with consistent quality across cavities. |

Ready to optimize your injection molding process with the right tooling?

At KINTEK, we specialize in providing robust lab equipment and consumables, including solutions for prototyping and production. Whether you're evaluating a 3-plate mold for its superior gating flexibility or need expert advice on the best mold design for your specific part quality and budget requirements, our team is here to help.

We understand that the right mold is critical to achieving dimensional stability, cosmetic perfection, and production efficiency. Let's discuss your project goals and find the most effective solution for your laboratory or production needs.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Cylindrical Press Mold for Lab Applications

- Special Heat Press Mold for Lab Use

People Also Ask

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- What is the physical role of graphite molds in vacuum hot pressing? Optimize Cu-Al2O3 Composite Densification

- What are the primary functions of graphite molds in NiCr powder metallurgy? Optimize Your Composite Material Density

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity