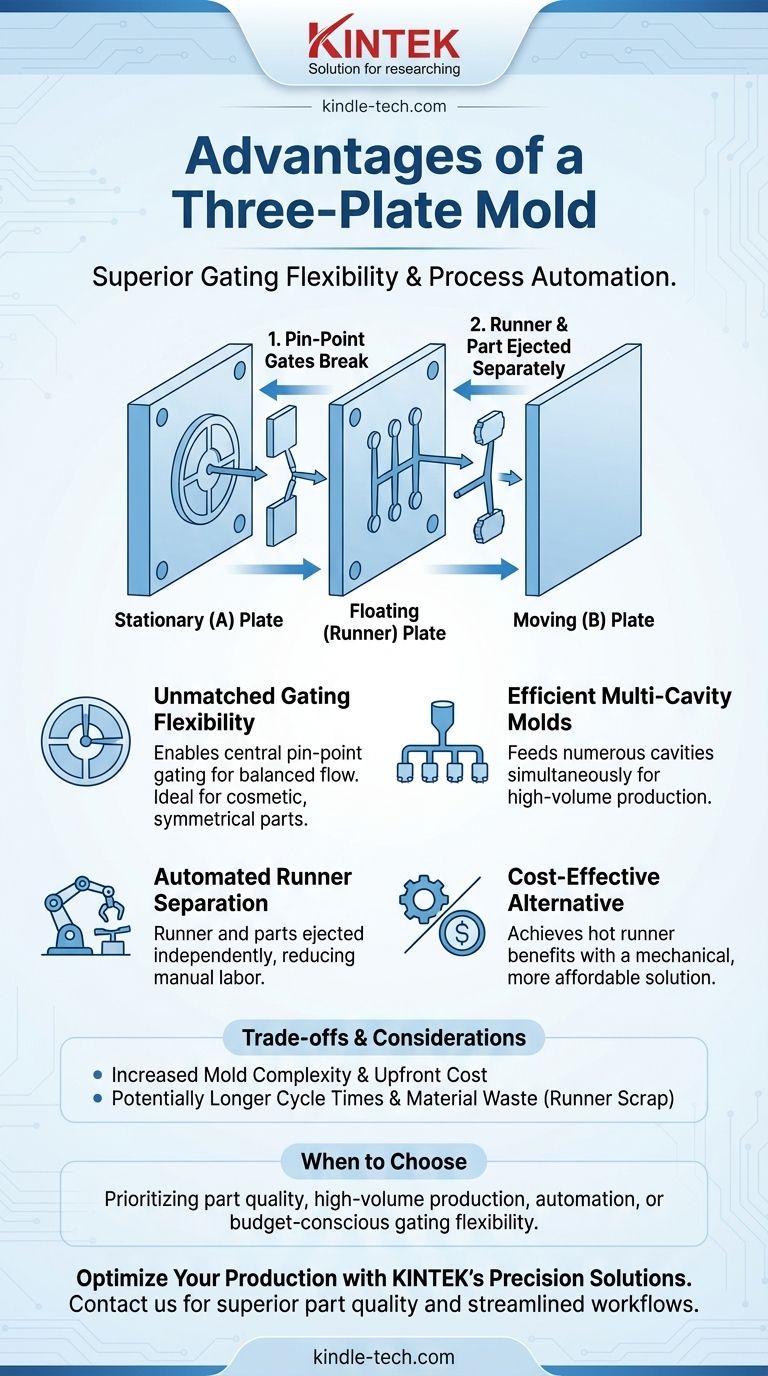

At its core, a three-plate mold provides superior gating flexibility and process automation. The primary advantages are the ability to place gates in the center of a part, feed multiple cavities from a single sprue, and automatically separate the runner system from the finished parts during ejection. This design often achieves the gating benefits of a complex hot runner system with a more cost-effective mechanical solution.

While more complex than a standard two-plate design, the three-plate mold solves critical production challenges. It provides an elegant mechanical solution for separating the runner from the part upon ejection, streamlining the production cycle for specific part geometries and high-volume needs.

The Core Problem a Three-Plate Mold Solves

The limitations of a basic two-plate mold are most apparent when you need to gate a part anywhere other than its outer edge. This is often necessary for cosmetic reasons or to ensure a balanced plastic flow in complex shapes. A three-plate mold is engineered specifically to overcome this limitation.

How it Works: The Second Parting Line

A standard mold has one parting line where the two halves separate. A three-plate mold introduces a second parting line, creating three distinct sections:

- Stationary (A) Plate: Mounts to the fixed platen of the press and contains the sprue bushing.

- Floating (Runner) Plate: Sits in the middle and contains the runner system that channels plastic from the sprue to the gates.

- Moving (B) Plate: Contains the core half of the part cavity and the ejector system.

During the molding cycle, the mold opens in two stages. The first opening occurs between the stationary plate and the floating plate, which breaks the small "pin-point" gates. The second opening then separates the floating plate from the moving plate, allowing the runner and the finished parts to be ejected separately.

Key Advantages Explained

The unique mechanical design of a three-plate mold delivers several powerful benefits that justify its increased complexity.

Unmatched Gating Flexibility

The most significant advantage is the ability to locate a gate almost anywhere on the part's surface. This is impossible with a standard two-plate mold, which is limited to edge gating.

Central pin-point gating is crucial for round or symmetrical parts, ensuring the plastic fills the cavity evenly from the center outwards. This prevents weld lines, improves dimensional stability, and enhances the part's cosmetic appearance.

Efficient Multi-Cavity Molds

A three-plate design is highly effective for high-volume production. A single sprue can feed a balanced runner system on the floating plate, which then delivers material to numerous cavities simultaneously. This allows for the efficient molding of many small parts in a single cycle.

Automated Runner Separation

Because the runner system is on a separate plate, it is ejected independently from the finished parts. This eliminates the manual labor required to trim the runner from each part. For high-volume production, this automation significantly reduces cycle time and operational costs.

A Cost-Effective Alternative to Hot Runners

Hot runner systems also allow for flexible gating and eliminate runner waste, but they are extremely expensive, complex, and require specialized maintenance. A three-plate mold achieves similar gating flexibility through a purely mechanical—and often more affordable—system, making it an excellent intermediate solution.

Understanding the Trade-offs

No design is perfect for every application. The advantages of a three-plate mold come with specific considerations.

Increased Mold Complexity and Cost

The addition of a third plate and the mechanisms required for the two-stage opening sequence make the mold more complex to design and manufacture. This results in a higher upfront tooling cost compared to a two-plate mold.

Potentially Longer Cycle Times

The increased press travel needed to open the mold in two stages can add a few seconds to the overall cycle time. While the automation saves labor time, the machine cycle itself may be slightly longer.

More Material Waste

The runner in a three-plate system can be quite large and complex. While it is separated automatically, it still represents plastic waste. This is a key disadvantage compared to a "runnerless" hot runner system, though the scrap can often be reground and reused.

When to Choose a Three-Plate Mold

Your decision should be driven by the specific requirements of your part and production goals.

- If your primary focus is part quality and cosmetics: A three-plate mold is ideal for central gating on visible surfaces, ensuring a balanced flow and minimizing blemishes.

- If your primary focus is high-volume production of small parts: The ability to efficiently feed multiple cavities symmetrically makes it a highly effective choice for mass production.

- If your primary focus is automation and reduced labor: The automatic separation of the runner from the parts eliminates a manual post-processing step, streamlining your workflow.

- If you need flexible gating but are budget-constrained: It provides a robust, mechanical alternative to achieve the gating benefits of a more expensive hot runner system.

Ultimately, selecting a three-plate mold is a strategic decision to prioritize automated, high-quality production when gating location is a critical design constraint.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Gating Flexibility | Enables central pin-point gating for balanced flow | Cosmetic parts, symmetrical components |

| Multi-Cavity Efficiency | Feeds multiple cavities from a single sprue | High-volume production of small parts |

| Automated Runner Separation | Automatically ejects runner and parts separately | Reducing labor costs and cycle times |

| Cost-Effective Alternative | Achieves hot runner benefits with mechanical simplicity | Budget-conscious projects needing flexible gating |

Ready to optimize your injection molding process with a three-plate mold? KINTEK specializes in precision lab equipment and consumables, serving laboratories and production facilities with innovative solutions. Our expertise can help you achieve superior part quality, streamline your production, and reduce operational costs. Contact us today to discuss how our solutions can meet your specific needs!

Visual Guide

Related Products

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Special Heat Press Mold for Lab Use

- Cylindrical Press Mold with Scale for Lab

- Ball Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

People Also Ask

- What functions do high-temperature molds perform in vacuum hot pressing? Enhance Metal Layered Composite Precision

- What function does the mold system serve during the hot press forming of SiCf/TC17/TB8? Achieve Precision Engineering

- What are compression molding's advantages and disadvantages? A Guide to Choosing the Right Process

- What role does a graphite mold play in hot-pressing Ti2AlN/TiN? Key Functions in FGM Fabrication

- Why must graphite molds containing diamond and aluminum mixed powders be treated in a drying oven? Prevent Sample Failure

- What are three-plate molds? Precision Injection Molding for Complex Parts

- What are the primary functions of high-purity graphite molds? Enhance Vacuum Hot Press Sintering Precision

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?