At its core, a three-plate mold offers superior gating flexibility over a two-plate design. This allows plastic to be injected at more strategic locations on the part, rather than being restricted to the part's outer edge. This fundamental difference enables more complex part geometries, improves part quality, and can serve as a cost-effective alternative to expensive hot runner systems.

A three-plate mold decouples the part from the runner system using a second parting line. This provides the freedom to place gates directly on the top surface of a part, a capability that is impossible with a standard two-plate mold and critical for achieving balanced plastic flow.

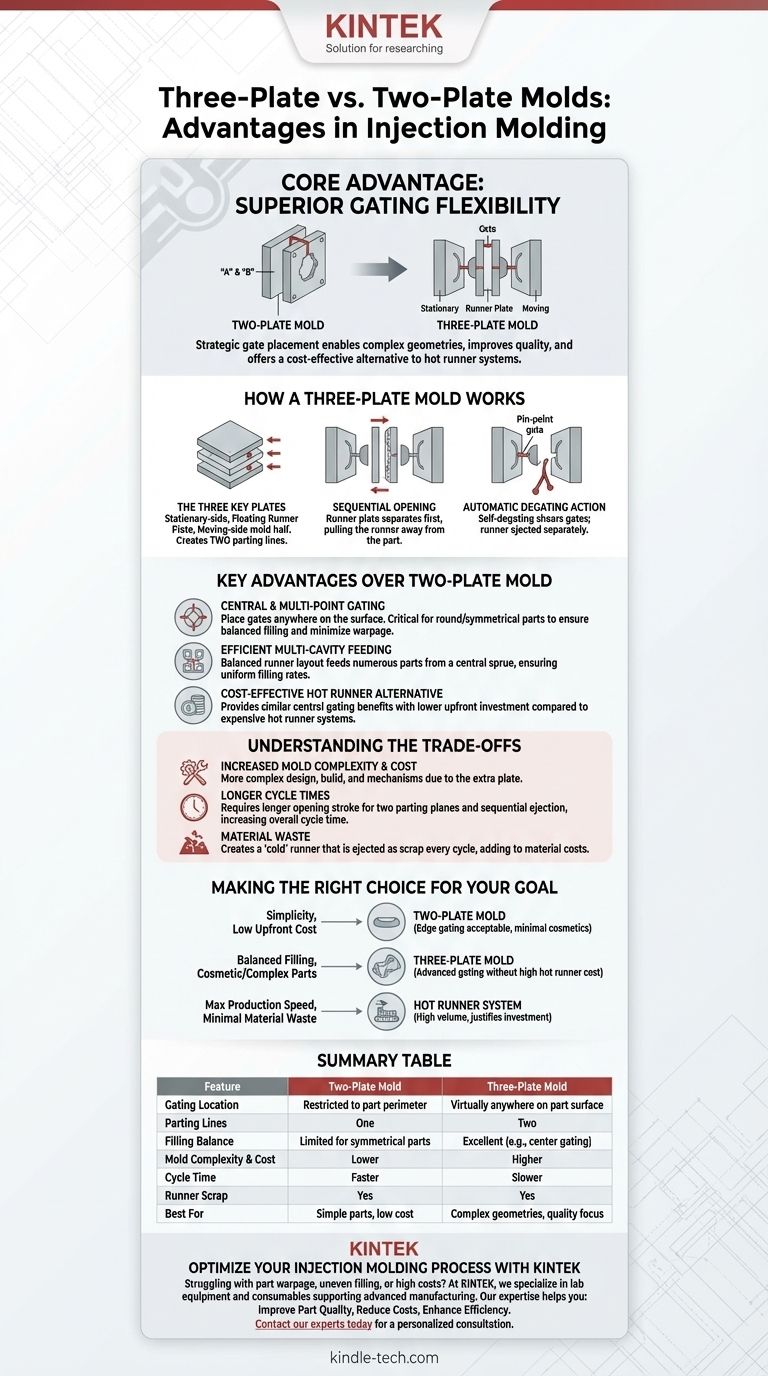

How a Three-Plate Mold Works

A standard injection mold has two plates—an "A" side and a "B" side—that meet at a single parting line. A three-plate mold introduces a third major plate, creating two parting lines.

The Three Key Plates

A three-plate system consists of the stationary-side mold half, a floating runner plate, and the moving-side mold half. When the mold opens, the runner plate separates from the stationary side, pulling the runner system away from the part before the part itself is ejected.

The Automatic Degating Action

This sequential opening automatically shears the small pin-point gates from the finished part. The runner system is then ejected separately. This self-degating action is a key feature of the design.

Key Advantages Over a Two-Plate Mold

The primary benefits stem from the ability to locate gates away from the mold's parting line.

Central and Multi-Point Gating

With a two-plate mold, the gate must be located on the part's perimeter at the parting line. A three-plate mold allows you to place one or more gates almost anywhere on the part's surface. This is critical for round or symmetrical parts where a center gate ensures uniform, balanced filling, minimizing warpage.

Feeding Multiple Cavities Efficiently

A three-plate design is highly effective for multi-cavity molds. It allows for a balanced runner layout that can feed numerous parts from a central sprue, ensuring all cavities fill at the same rate and pressure.

A Cost-Effective Hot Runner Alternative

Hot runner systems also allow for central gating but keep the plastic molten all the way to the part, eliminating runner scrap. However, they are significantly more expensive and complex to maintain. A three-plate mold provides similar gating benefits with a lower upfront investment, making it an excellent intermediate solution.

Understanding the Trade-offs

While powerful, the three-plate design is not universally superior. Its advantages come with clear trade-offs.

Increased Mold Complexity and Cost

The addition of a runner plate and the mechanisms required for a sequential opening sequence make the mold more complex and expensive to design and build than a simple two-plate mold.

Longer Cycle Times

The molding machine must have a sufficiently long opening stroke to accommodate the two separate parting planes. The process of opening, ejecting the runner, and then opening again to eject the parts adds time to the overall cycle compared to a two-plate mold.

Material Waste

Unlike a hot runner system, a three-plate mold creates a "cold" runner that is ejected every cycle. This runner is scrap material, which can become a significant cost factor in high-volume production with expensive resins.

Making the Right Choice for Your Goal

Selecting the correct mold type requires balancing part design requirements, production volume, and budget.

- If your primary focus is simplicity and low upfront cost: A two-plate mold is the best choice for parts where edge gating is acceptable and cosmetic requirements are minimal.

- If your primary focus is balanced filling for cosmetic or complex parts: A three-plate mold provides the advanced gating needed for high-quality parts without the high cost of a hot runner system.

- If your primary focus is maximum production speed and minimal material waste: A hot runner system is the superior choice for high-volume manufacturing, as the material and cycle time savings will justify the initial investment.

Choosing the right mold is a foundational decision that directly impacts part quality and production efficiency.

Summary Table:

| Feature | Two-Plate Mold | Three-Plate Mold |

|---|---|---|

| Gating Location | Restricted to part perimeter | Virtually anywhere on part surface |

| Parting Lines | One | Two |

| Filling Balance | Limited for symmetrical parts | Excellent (e.g., center gating) |

| Mold Complexity & Cost | Lower | Higher |

| Cycle Time | Faster | Slower |

| Runner Scrap | Yes | Yes |

| Best For | Simple parts, low cost | Complex geometries, quality focus |

Optimize Your Injection Molding Process with KINTEK

Struggling with part warpage, uneven filling, or high costs for complex geometries? The right mold design is critical to your success. At KINTEK, we specialize in providing the lab equipment and consumables that support advanced manufacturing processes like injection molding.

Our expertise helps you:

- Improve Part Quality: Achieve balanced filling and superior cosmetics.

- Reduce Costs: Find the most efficient mold solution for your production volume.

- Enhance Efficiency: Streamline your prototyping and production workflows.

Whether you're developing new products or scaling production, KINTEK is your partner for precision and reliability. Contact our experts today for a personalized consultation and let us help you select the perfect solution for your laboratory and manufacturing needs.

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Cylindrical Press Mold with Scale for Lab

- Special Heat Press Mold for Lab Use

People Also Ask

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- Why are custom pressure molds used during the hot pressing process for solid polymer electrolytes?

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation