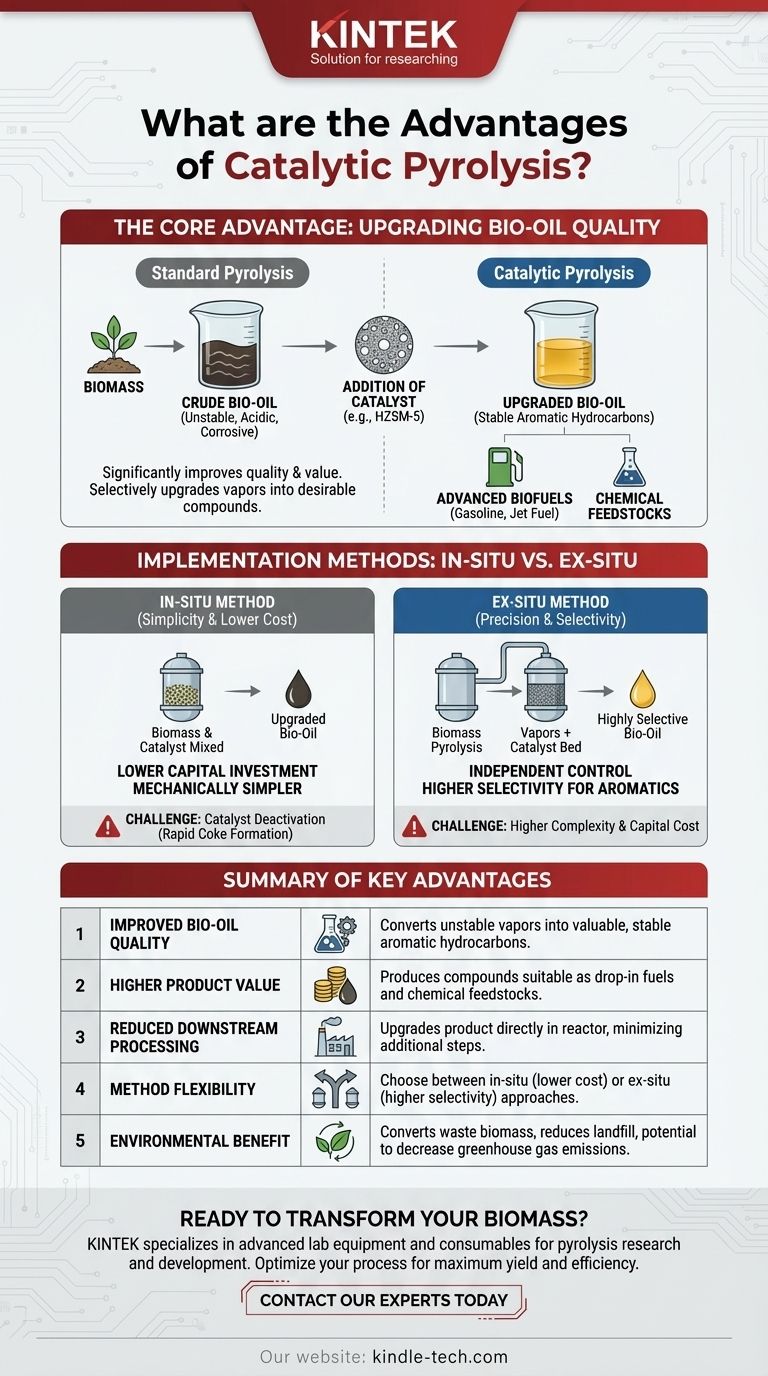

The primary advantage of catalytic pyrolysis is its ability to significantly improve the quality and value of the final bio-oil product. Unlike standard pyrolysis which produces a complex, often unstable liquid, adding a catalyst selectively upgrades the pyrolysis vapors into more desirable compounds, such as aromatic hydrocarbons, making them more suitable for use as advanced biofuels and chemical feedstocks.

The core function of a catalyst in pyrolysis is not merely to aid in decomposition, but to actively steer the chemical reactions toward producing a more refined, stable, and valuable end-product directly from the reactor, reducing the need for extensive downstream processing.

The Core Advantage: Upgrading Bio-Oil Quality

Standard fast pyrolysis creates a liquid known as bio-oil. While useful, this crude bio-oil is often acidic, corrosive, and chemically unstable, limiting its direct application. Catalytic pyrolysis addresses this fundamental problem.

From Unstable Vapors to Valuable Hydrocarbons

The addition of a catalyst, such as HZSM-5, intercepts the hot vapors produced during pyrolysis. It promotes reactions that convert the unstable oxygenated compounds into stable aromatic hydrocarbons.

These hydrocarbons are the building blocks for gasoline, jet fuel, and valuable chemicals, making the output of catalytic pyrolysis far more valuable than standard bio-oil.

Enhancing Fuel Properties

By increasing the concentration of aromatic hydrocarbons, the process creates a product with higher energy density and improved stability. This moves the output from a crude "bio-crude" toward a potential "drop-in" fuel that is more compatible with existing fuel infrastructure.

How Catalytic Pyrolysis is Implemented

The method of introducing the catalyst into the process creates two distinct approaches, each with its own operational advantages and disadvantages.

The In-Situ Method: Simplicity and Lower Cost

In in-situ catalytic pyrolysis, the biomass feedstock and the catalyst are mixed together inside a single reactor.

This approach is mechanically simpler and generally requires a lower initial capital investment because it avoids the need for a second reactor vessel.

The Ex-Situ Method: Precision and Selectivity

In ex-situ catalytic pyrolysis, the process is split into two stages. The biomass is first pyrolyzed in one reactor, and the resulting vapors are then passed over a separate, dedicated catalyst bed in a second reactor.

This separation allows for independent control over both the pyrolysis and the catalytic upgrading conditions, leading to higher selectivity for producing specific, desirable aromatics.

Understanding the Trade-offs

While catalytic pyrolysis offers clear advantages in product quality, the choice of method involves significant trade-offs between cost, complexity, and performance.

In-Situ's Challenge: Catalyst Deactivation

The primary drawback of the in-situ method is faster catalyst deactivation. The direct contact between the catalyst, biomass, and char byproducts leads to the rapid formation of coke on the catalyst surface, reducing its effectiveness and requiring more frequent regeneration or replacement.

Ex-Situ's Challenge: Complexity and Capital Cost

The main downside of the ex-situ method is its increased complexity and higher capital cost. Operating and maintaining a two-reactor system is inherently more demanding and expensive than a single-reactor setup.

Inherited Environmental Benefits

Both methods retain the core environmental advantages of pyrolysis. They convert organic waste into valuable products, reduce the volume of waste sent to landfills, and can help decrease greenhouse gas emissions by providing an alternative to fossil fuels.

Making the Right Choice for Your Goal

Your choice between in-situ and ex-situ catalytic pyrolysis depends entirely on your project's primary objective and financial constraints.

- If your primary focus is maximizing product quality and selectivity for specific chemicals: The ex-situ method provides superior control and higher yields of valuable aromatics, justifying its higher complexity.

- If your primary focus is minimizing initial capital investment for a simpler process: The in-situ method offers a more direct and cost-effective pathway to producing an upgraded bio-oil, provided you can manage catalyst deactivation.

Ultimately, applying the right catalytic strategy allows you to purposefully transform low-value biomass and waste streams into high-value, market-ready resources.

Summary Table:

| Advantage | Description |

|---|---|

| Improved Bio-Oil Quality | Converts unstable vapors into valuable, stable aromatic hydrocarbons. |

| Higher Product Value | Produces compounds suitable as drop-in fuels and chemical feedstocks. |

| Reduced Downstream Processing | Upgrades product directly in the reactor, minimizing additional refining steps. |

| Method Flexibility | Choose between in-situ (lower cost) or ex-situ (higher selectivity) approaches. |

| Environmental Benefit | Converts waste biomass into useful products, reducing landfill and emissions. |

Ready to transform your biomass into high-value biofuels?

KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you are exploring in-situ or ex-situ catalytic methods, our solutions help you optimize your process for maximum yield and efficiency.

Contact our experts today to discuss how our equipment can accelerate your biofuel projects and help you achieve your sustainability goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas