In summary, magnetron sputtering offers significant advantages in producing high-quality thin films due to its exceptional control, versatility, and efficiency. By using magnetic fields to enhance the plasma used for deposition, the process achieves higher deposition rates, superior film density, and stronger adhesion compared to many alternative methods, all while operating at lower temperatures and pressures.

The core advantage of magnetron sputtering stems from its use of magnetic fields to confine electrons near the target material. This creates a dense, stable plasma that dramatically increases the efficiency of the sputtering process, leading to higher quality films at a faster rate.

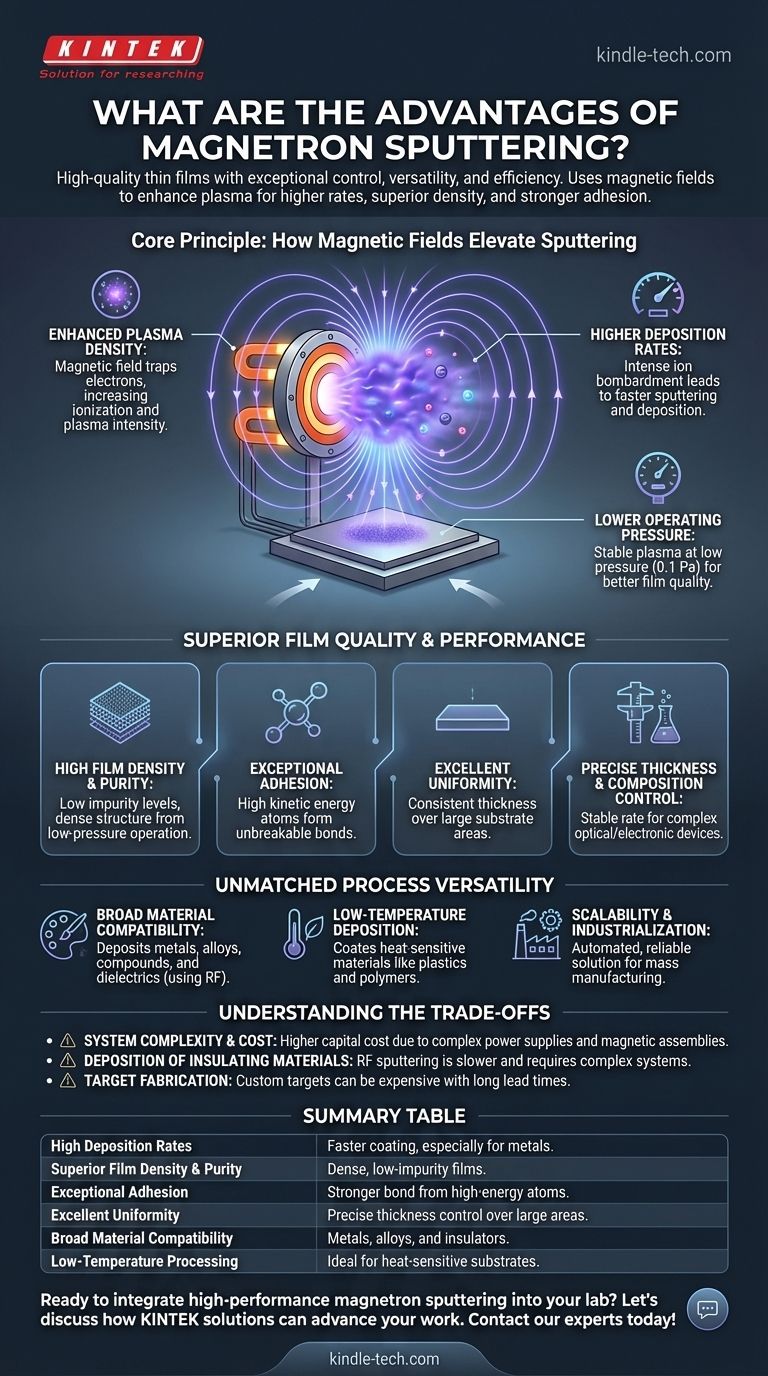

The Core Principle: How Magnetic Fields Elevate Sputtering

At its heart, magnetron sputtering is an enhanced version of standard sputtering. The "magnetron" is the key innovation, consisting of strong magnets placed behind the target material.

Enhanced Plasma Density

The magnetic field traps electrons in a circular path directly in front of the target's surface. This confinement drastically increases the probability of these electrons colliding with and ionizing the neutral gas atoms (like Argon).

This action creates a much denser, more intense plasma in the precise location where it is needed most, without having to increase the overall gas pressure in the chamber.

Higher Deposition Rates

The dense plasma generates a massive number of positive ions. These ions are accelerated into the target, striking it with high energy and dislodging, or "sputtering," atoms from its surface.

Because the ion bombardment is so much more intense than in non-magnetron systems, the rate at which material is sputtered and deposited onto the substrate is significantly higher, especially for metals.

Lower Operating Pressure

The efficiency of the magnetic confinement means that a stable plasma can be sustained at very low pressures, often around 0.1 Pa.

Operating at low pressure reduces the chance that the sputtered atoms will collide with gas molecules on their way to the substrate. This results in a more direct path and higher-energy arrival, which is critical for film quality.

Superior Film Quality and Performance

The unique physics of the magnetron sputtering process directly translates into films with demonstrably better physical and mechanical properties.

High Film Density and Purity

Films produced by magnetron sputtering are exceptionally dense and have very low impurity levels. This is a direct result of the lower operating pressure, which minimizes the incorporation of ambient gas into the growing film.

Exceptional Adhesion

The sputtered atoms arrive at the substrate with higher kinetic energy compared to atoms in thermal evaporation. This energy helps them form a stronger, virtually unbreakable bond with the substrate surface.

Excellent Uniformity Over Large Areas

The process is highly controllable and can be engineered to produce films with excellent thickness uniformity, even across very large substrate areas. This makes it ideal for industrial applications where consistency is critical.

Precise Thickness and Composition Control

Magnetron sputtering provides a stable and repeatable deposition rate that is directly proportional to the power applied. This allows for the precise control of film thickness and composition, which is essential for creating complex optical or electronic devices.

Unmatched Process Versatility

Beyond film quality, the technique is renowned for its flexibility, accommodating a vast range of materials and substrates.

Broad Material Compatibility

Unlike thermal evaporation, which is limited by a material's melting point, magnetron sputtering can deposit almost any metal, alloy, or compound. This includes high-melting-point materials and dielectrics (insulators), which are deposited using Radio Frequency (RF) power.

Low-Temperature Deposition

The process transfers very little heat to the substrate. This allows for the coating of heat-sensitive materials, such as plastics, polymers, and other delicate components that would be damaged by higher-temperature processes.

Scalability and Industrialization

Magnetron sputtering equipment is well-suited for automation and continuous production. Its reliability, high deposition rates, and uniformity make it a cost-effective and scalable solution for mass manufacturing.

Understanding the Trade-offs

While powerful, magnetron sputtering is not the universal solution for every application. Understanding its limitations is key to making an informed decision.

System Complexity and Cost

Magnetron sputtering systems are more complex and carry a higher initial capital cost than simpler techniques like thermal evaporation. The need for high-performance power supplies, vacuum systems, and magnetic assemblies adds to the expense.

Deposition of Insulating Materials

While DC sputtering of metals is very fast, the deposition of insulating (dielectric) materials requires RF power. RF sputtering is generally a slower process and requires more complex and expensive power delivery systems to avoid charge build-up on the target.

Target Fabrication

The process requires a source material in the form of a sputtering target. Fabricating custom alloy or compound targets can sometimes be expensive and have long lead times compared to simply using powders or pellets in an evaporation process.

Making the Right Choice for Your Application

Ultimately, the choice of deposition technology depends entirely on your specific goals for the final film.

- If your primary focus is high-performance optical or electronic films: The exceptional purity, density, and precise thickness control of magnetron sputtering make it the superior choice.

- If your primary focus is industrial-scale protective or mechanical coatings: The combination of high deposition rates, excellent adhesion, and uniformity over large areas is ideal for robust, scalable production.

- If your primary focus is coating delicate or heat-sensitive substrates: The low-temperature nature of the process gives you the flexibility to coat materials like plastics that other methods cannot.

- If your primary focus is simple metallic coatings on a limited budget: A less complex method like thermal evaporation may be a more cost-effective starting point, provided its limitations in density and adhesion are acceptable.

By understanding these core principles and trade-offs, you can confidently determine if magnetron sputtering is the right tool to achieve your objective.

Summary Table:

| Key Advantage | Description |

|---|---|

| High Deposition Rates | Faster coating, especially for metals, due to intense plasma. |

| Superior Film Density & Purity | Dense, low-impurity films from low-pressure operation. |

| Exceptional Adhesion | Stronger bond from high-energy atom arrival at the substrate. |

| Excellent Uniformity | Precise thickness control, even over large areas. |

| Broad Material Compatibility | Deposits metals, alloys, and insulators (with RF power). |

| Low-Temperature Processing | Ideal for heat-sensitive substrates like plastics. |

Ready to integrate high-performance magnetron sputtering into your lab?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your research and production needs. Our expertise in thin-film deposition technologies can help you achieve unparalleled film quality, consistency, and efficiency.

Let's discuss how a magnetron sputtering solution from KINTEK can advance your work. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

People Also Ask

- What is the function of a laboratory orbital shaker during the Fenton reaction? Optimize Leather Wastewater Treatment

- What is the pressure in a sputter coater? Master Base vs. Working Pressure for Superior Coatings

- What is the effect of moisture content on biomass pyrolysis? Optimize Your Biomass Conversion Efficiency

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- What property does KBr have that makes it suitable for the infrared region? Unlock Clear IR Spectroscopy Analysis

- What are the challenges associated with increasing the use of bioenergy? Navigating the Land, Carbon, and Economic Trade-offs

- What is the uniformity of e beam evaporation? Achieve Precise, Uniform Thin Films

- What is bio-oil used for pyrolysis? Unlocking Renewable Fuel & Chemical Potential