In thin-film deposition, the primary advantages of sputtering over thermal evaporation are superior film quality and greater process control. Sputtered films exhibit significantly better adhesion, higher density, and more uniform coverage, especially on complex surfaces. This is because the deposition process involves high-energy particles, which embed into the substrate and create a more robust film.

The choice between sputtering and thermal evaporation is a fundamental trade-off. Sputtering is the superior method for producing high-quality, dense, and adherent films with complex materials, while thermal evaporation offers a faster, simpler process for applications where film performance is less critical.

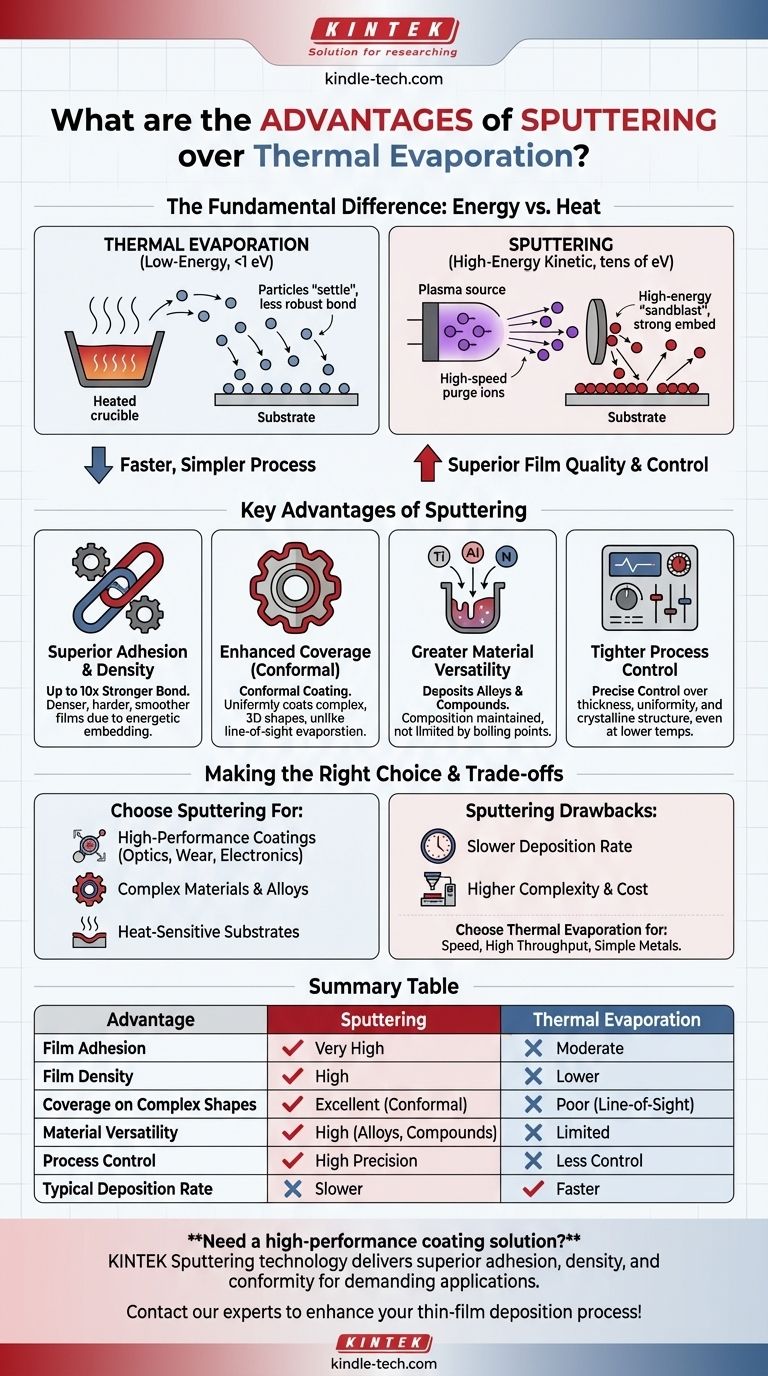

The Fundamental Difference: Energy vs. Heat

The advantages of sputtering stem from its distinct physical mechanism compared to thermal evaporation. Both are forms of Physical Vapor Deposition (PVD), but they deliver material to the substrate in fundamentally different ways.

Thermal Evaporation: A Low-Energy Process

Thermal evaporation works by heating a source material in a vacuum until its atoms or molecules boil off, travel through the chamber, and condense on a substrate.

The particles arriving at the substrate have very low kinetic energy, typically less than 1 eV. They essentially just "settle" on the surface, forming a bond that can be less robust.

Sputtering: A High-Energy Kinetic Process

Sputtering uses a plasma to create high-energy ions (usually argon) that are accelerated into a source material, or "target." This collision acts like a microscopic sandblaster, knocking atoms off the target.

These ejected atoms travel toward the substrate with significantly higher kinetic energy, often in the range of tens of eV. This energy is the source of sputtering's key benefits.

Key Advantages of Sputtering

The high-energy nature of the sputtered atoms directly translates into improved film characteristics and process capabilities.

Superior Film Adhesion and Density

The high energy of sputtered particles causes them to physically embed into the top layer of the substrate, creating an exceptionally strong bond. Adhesion strength can be ten times greater than that of evaporated films.

This energetic arrival also packs the atoms together more tightly, resulting in films that are denser, harder, and smoother than their evaporated counterparts.

Enhanced Coverage on Complex Shapes

Because sputtered atoms are ejected in many directions and scatter within the plasma, they can coat complex, three-dimensional substrates more uniformly.

This ability to produce a "conformal" coating is a major advantage over thermal evaporation, which is a line-of-sight process and struggles to evenly coat shadowed areas or intricate geometries.

Greater Material Versatility

Sputtering can deposit a vast range of materials, including alloys and compounds. Since the process mechanically ejects atoms rather than boiling them, the composition of a sputtered alloy film is much closer to the source target.

Thermal evaporation is limited by material boiling points, making it difficult to deposit alloys with components that evaporate at different rates or to deposit materials with very high melting points.

Tighter Control Over Film Properties

Sputtering systems offer more parameters for fine-tuning the deposition process. This allows for precise control over film thickness, uniformity, and even crystalline structure.

Crystalline films can often be achieved at lower substrate temperatures compared to evaporation, which is critical when coating heat-sensitive materials like plastics.

Understanding the Trade-offs

Despite its advantages in film quality, sputtering is not always the optimal choice. It comes with its own set of limitations.

Deposition Rate: The Primary Drawback

The most significant disadvantage of sputtering is its slower deposition rate. The process of kinetically ejecting atoms is less efficient than boiling them off in bulk.

For applications requiring thick films or high throughput, thermal evaporation is often much faster and more cost-effective.

Process Complexity

Sputtering systems are generally more complex than thermal evaporators. They require high-voltage power supplies, gas-handling systems to manage the plasma, and often magnetic fields (in magnetron sputtering) to improve efficiency.

This complexity can translate to higher initial equipment cost and more involved maintenance.

Making the Right Choice for Your Application

Selecting the correct deposition method requires matching the process capabilities to your project's primary goal.

- If your primary focus is high-performance coatings: Choose sputtering for its superior adhesion, density, and hardness, which are critical for optical, wear-resistant, or electronic applications.

- If your primary focus is speed and high throughput: Choose thermal evaporation for its faster deposition rates, especially for simple metal coatings where ultimate film quality is secondary.

- If your primary focus is depositing complex materials or alloys: Choose sputtering for its ability to maintain stoichiometry and deposit materials that are difficult or impossible to evaporate.

- If your primary focus is coating heat-sensitive substrates: Choose sputtering, as it generally runs at lower substrate temperatures and provides better quality films under those conditions.

Ultimately, understanding the physics of each process empowers you to select the precise tool needed to achieve your desired film characteristics.

Summary Table:

| Advantage | Sputtering | Thermal Evaporation |

|---|---|---|

| Film Adhesion | Very High | Moderate |

| Film Density | High | Lower |

| Coverage on Complex Shapes | Excellent (Conformal) | Poor (Line-of-Sight) |

| Material Versatility | High (Alloys, Compounds) | Limited |

| Process Control | High Precision | Less Control |

| Typical Deposition Rate | Slower | Faster |

Need a high-performance coating solution for your lab?

Sputtering technology from KINTEK delivers the superior adhesion, density, and conformity required for demanding applications in optics, electronics, and wear-resistant coatings. Our lab equipment and consumables are designed to provide the precise control and material versatility your research demands.

Contact our experts today to discuss how our sputtering systems can enhance your thin-film deposition process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What are the drawbacks of PECVD? Understanding the Trade-offs of Low-Temperature Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition