While best known as a diamond simulant, the applications of cubic zirconia (CZ) extend far beyond jewelry into demanding industrial, scientific, and medical fields. Its unique combination of diamond-like optical properties, high-temperature stability, and ceramic-like durability makes it a surprisingly versatile engineered material.

Cubic zirconia's true value lies in its duality: it is both an optically brilliant crystal used for adornment and a mechanically tough ceramic used for high-performance functional components. Understanding this dual nature is key to appreciating its wide range of applications.

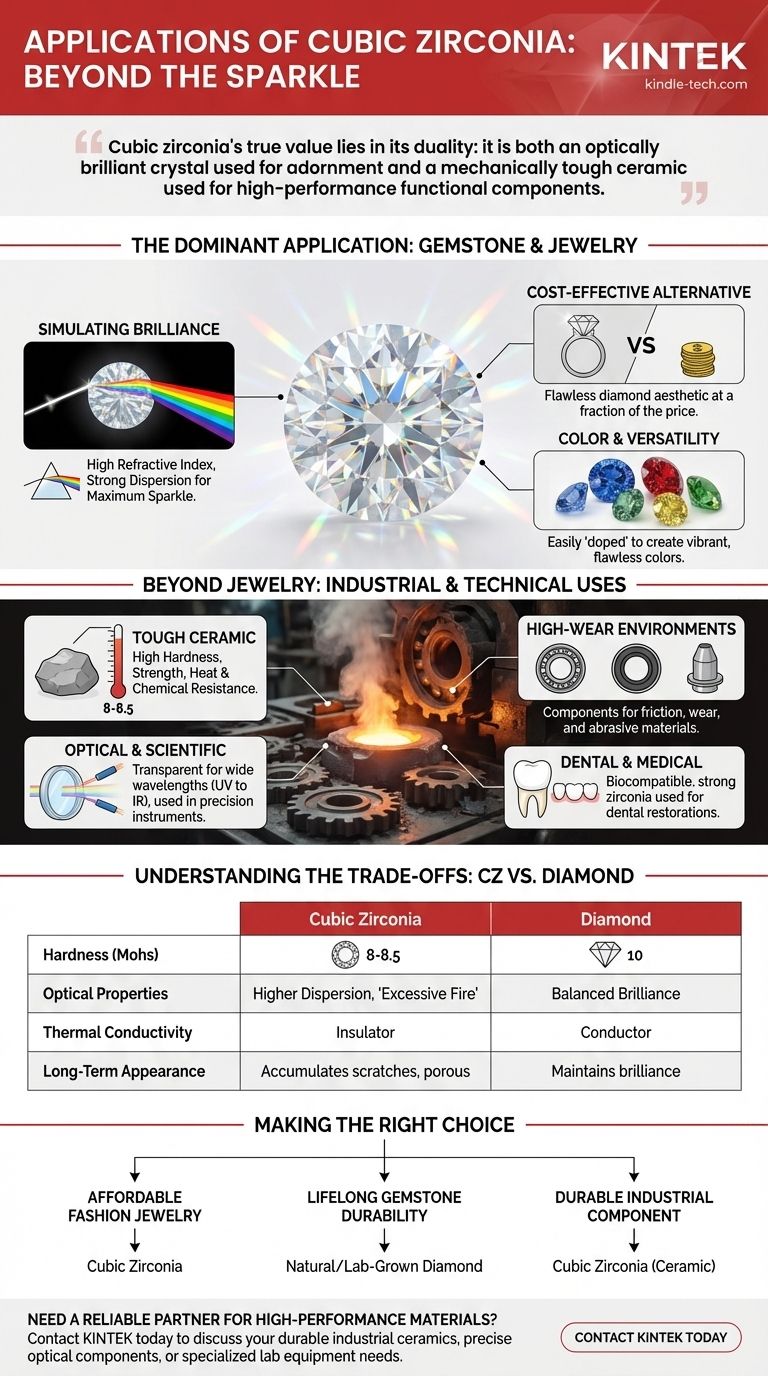

The Dominant Application: Gemstone and Jewelry

The vast majority of cubic zirconia produced is for the jewelry market. Its popularity stems from its ability to convincingly mimic a diamond at a fraction of the cost.

Simulating a Diamond's Brilliance

Cubic zirconia possesses a high refractive index and strong dispersion. This means it bends light and splits it into a rainbow of colors very effectively, giving it the "sparkle" and "fire" associated with a well-cut diamond.

The Cost-Effective Alternative

The primary driver for its use in jewelry is economics. CZ provides the aesthetic of a flawless, colorless diamond for a very small percentage of the price, making large, dramatic jewelry accessible.

Color and Versatility

Unlike diamonds, CZ can be easily and affordably "doped" with various metal oxides during its creation. This process allows manufacturers to produce a consistent, vibrant, and flawless stone in virtually any color imaginable.

Beyond Jewelry: The Industrial and Technical Uses

The same properties that make CZ beautiful also make it incredibly tough and resilient, opening the door to a range of technical applications where performance is critical.

A Surprisingly Tough Ceramic

Cubic zirconia is the cubic crystalline form of zirconium dioxide. This gives it exceptional hardness (8 to 8.5 on the Mohs scale), high strength, and excellent resistance to heat and chemical corrosion.

Applications in High-Wear Environments

Its durability makes it suitable for components that experience significant friction and wear. This includes use in specialty bearings, seals, valves, and nozzles for handling abrasive materials.

Optical and Scientific Instruments

Because it is transparent over a wide range of light wavelengths (including parts of the UV and infrared spectrum), CZ is used as an optical window in harsh environments. It's also used in fiber optic connectors and sleeves where precise alignment and durability are essential.

Dental and Medical Applications

The base material of CZ, zirconium dioxide, is highly biocompatible, meaning it does not react with biological tissue. In a different stabilized form (often called zirconia), it is widely used for dental crowns, bridges, and implants due to its strength and tooth-like appearance.

Understanding the Trade-offs: CZ vs. Diamond

While an excellent material, it is crucial to understand how CZ differs from the material it most often imitates, as well as other alternatives like moissanite.

Hardness and Durability

A diamond is the hardest known natural material, scoring a 10 on the Mohs scale. Cubic zirconia's hardness of 8-8.5 is excellent and resists scratching from most everyday encounters, but it can be scratched by harder materials and will show wear over many years.

Optical Properties

To a trained eye, CZ's dispersion is actually higher than a diamond's, producing more colorful "fire" or rainbow flashes. This excessive fire can be a giveaway that it is not a diamond.

Thermal Conductivity

The easiest way to differentiate the two is with a jeweler's thermal probe. Diamonds are exceptional thermal conductors (they disperse heat quickly), while CZ is a thermal insulator. Most diamond testers rely on this principle.

Long-Term Appearance

Over time, the surface of cubic zirconia can accumulate microscopic scratches that give it a slightly cloudy or dull appearance. It is also more porous than a diamond and can absorb oils, requiring more frequent cleaning to maintain its brilliance.

Making the Right Choice for Your Goal

Ultimately, cubic zirconia is not a "bad" or "good" material; it is a material with a specific set of properties suited for different goals.

- If your primary focus is affordable and beautiful fashion jewelry: Cubic zirconia is an outstanding choice, offering maximum visual impact for a minimal cost.

- If your primary focus is a lifelong gemstone with maximum durability: A natural or lab-grown diamond remains the superior option due to its unparalleled hardness.

- If your primary focus is a durable, high-performance industrial component: CZ's ceramic properties make it a strong candidate for high-wear, high-temperature, or corrosive environments.

Understanding cubic zirconia's properties empowers you to leverage it effectively, whether for a brilliant accessory or a mission-critical part.

Summary Table:

| Application Area | Key Properties Utilized | Examples of Use |

|---|---|---|

| Jewelry & Gemstones | High Refractive Index, Strong Dispersion, Color Versatility | Diamond simulants, fashion jewelry in various colors |

| Industrial Components | High Hardness (8-8.5 Mohs), Heat Resistance, Durability | Bearings, seals, valves, nozzles for abrasive materials |

| Optical & Scientific | Transparency (UV to IR), Durability, Precision | Optical windows, fiber optic connectors, scientific instruments |

| Dental & Medical | Biocompatibility, Strength, Tooth-like Appearance | Dental crowns, bridges, implants (as zirconia) |

Need a Reliable Partner for High-Performance Materials?

Whether your project requires durable industrial ceramics, precise optical components, or specialized lab equipment, KINTEK has the expertise and solutions to meet your needs. We specialize in providing high-quality lab equipment and consumables, serving a wide range of laboratory and industrial applications.

Contact KINTEK today to discuss how our materials and equipment can enhance your project's performance and durability.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What is the process of lab created diamonds? A Clear Guide to HPHT & CVD Methods

- What is the main difference between CVD and natural diamond? Origin, Purity, and Value Explained

- Are CVD diamonds better than HPHT? The Real Truth About Lab-Grown Diamond Quality

- What is CVD diamond? The Ultimate Guide to Lab-Grown Diamonds and Their Uses

- What are the common sources of contamination during CVD diamond growth? Improve Purity and Quality Control