At its core, converting plastic waste into fuel offers two primary benefits: it provides a method for managing hard-to-recycle plastics that would otherwise end up in landfills or oceans, and it creates a valuable energy source. This process, most commonly pyrolysis, transforms a persistent environmental liability into a potential asset, offering a lower carbon footprint than extracting and refining new fossil fuels.

While not a perfect solution, plastic-to-fuel technology represents a strategic tool in a circular economy. It tackles the challenge of non-recyclable plastic waste by converting it into usable energy, but its true value depends on efficient process control and careful integration with broader waste management systems.

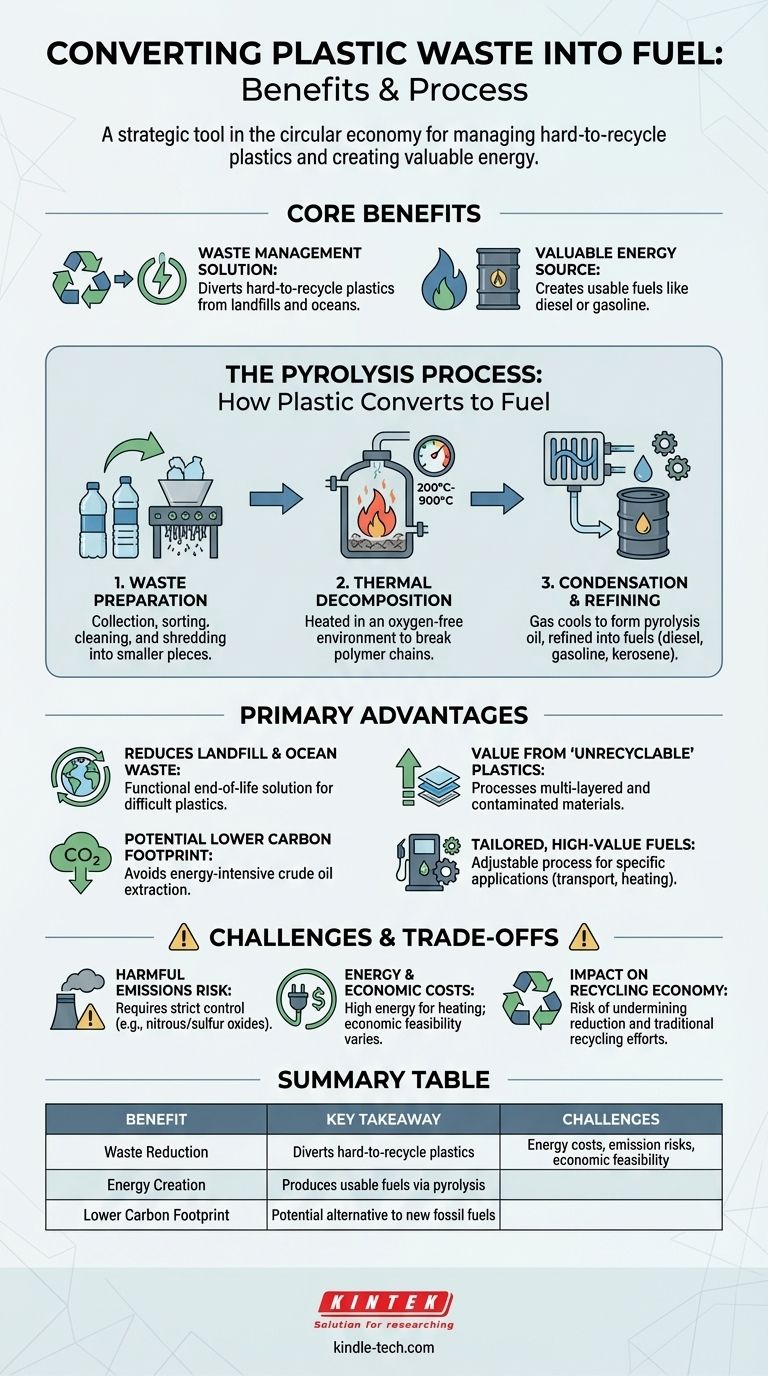

How Plastic is Converted to Fuel: The Pyrolysis Process

Pyrolysis is the most common technology for this conversion. It is a process of thermal decomposition, meaning it uses high heat in an oxygen-free environment to break down materials.

Step 1: Waste Preparation

The process begins with collecting and sorting plastic waste. The material is then pretreated to remove impurities, cleaned, and often shredded or ground into a consistent, smaller size for efficient heating.

Step 2: Thermal Decomposition

This prepared plastic is loaded into a sealed pyrolysis reactor. It is then heated to extreme temperatures, typically between 200°C and 900°C (392°F and 1652°F), without the presence of oxygen. This intense heat breaks the long polymer chains of the plastic into smaller, volatile hydrocarbon molecules, turning the solid plastic into a gas.

Step 3: Condensation and Refining

This hot gas is then directed into a condensation system. As it cools, the gas condenses into a liquid, which is a synthetic crude oil known as pyrolysis oil. This raw oil can be further refined to produce various types of fuel, such as diesel, gasoline, or kerosene, similar to how crude oil is refined.

The Primary Advantages of Plastic-to-Fuel

The appeal of this technology lies in its ability to address both waste management and energy needs simultaneously.

Reducing Landfill and Ocean Waste

The most significant benefit is its potential to divert enormous quantities of plastic from landfills and natural ecosystems. It provides a functional end-of-life solution for plastics that are difficult or economically unviable to recycle through traditional mechanical means.

Creating Value from "Unrecyclable" Plastics

Many common plastics, such as multi-layered films, contaminated containers, and certain mixed plastics, cannot be easily recycled. Pyrolysis can process these materials, turning low-value or negative-value waste into a marketable commodity.

A Potentially Lower Carbon Footprint

Creating fuel from existing plastic waste avoids the energy-intensive process of extracting and transporting new crude oil. When managed correctly, the resulting fuel can have a lower overall carbon footprint compared to its fossil-derived equivalent.

Producing Tailored, High-Value Fuels

The pyrolysis process allows for a degree of control over the final output. By adjusting temperature, pressure, and catalysts, operators can tailor the chemical composition of the fuel for specific applications, such as transportation or industrial heating.

Understanding the Trade-offs and Challenges

Objectivity requires acknowledging that this technology is not a perfect solution and comes with significant challenges that must be managed.

The Risk of Harmful Emissions

While some claim the process is clean, this is not inherently true. If not properly controlled and scrubbed, pyrolysis can release harmful pollutants, including nitrous oxides and sulfur dioxides. The environmental viability of a plant depends entirely on its emission control and gas handling technology.

The Energy and Economic Costs

The process is energy-intensive, as it requires maintaining extremely high temperatures. The economic feasibility can also be a challenge, sometimes leading to situations where regions must import plastic waste to keep plants operating at a profitable scale.

Impact on the Broader Recycling Economy

There is a valid concern that an over-reliance on plastic-to-fuel could undermine efforts to reduce plastic consumption at its source. It may also compete with and divert funding from other recycling and reuse initiatives, creating a perverse incentive to continue producing single-use plastics.

How to Apply This to Your Goal

Your perspective on plastic-to-fuel technology will depend on your primary objective.

- If your primary focus is municipal waste management: View this as a complementary solution for the stream of non-recyclable plastics, not a replacement for established recycling and waste reduction programs.

- If your primary focus is technology and investment: The key variables are process efficiency, the quality of emissions control systems, and the market value of the final fuel product.

- If your primary focus is environmental policy: Advocate for a "waste hierarchy" where plastic-to-fuel is prioritized above landfilling but below the preferred goals of reducing, reusing, and recycling.

Ultimately, converting plastic to fuel is a powerful technology that reframes a global waste problem into an energy opportunity.

Summary Table:

| Benefit | Key Takeaway |

|---|---|

| Waste Reduction | Diverts hard-to-recycle plastics from landfills and oceans. |

| Energy Creation | Produces usable fuels like diesel or gasoline via pyrolysis. |

| Lower Carbon Footprint | Offers a potential alternative to extracting new fossil fuels. |

| Challenges | Includes energy costs, emission risks, and economic feasibility. |

Ready to explore advanced pyrolysis or lab-scale solutions for your waste management or R&D projects? KINTEK specializes in high-quality laboratory equipment and consumables, providing the precise tools needed for pyrolysis research, process optimization, and material analysis. Whether you're developing new recycling technologies or analyzing fuel outputs, our equipment delivers the reliability and accuracy your lab requires. Contact our experts today to discuss how we can support your specific laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- CVD Diamond for Thermal Management Applications

- Non Consumable Vacuum Arc Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time