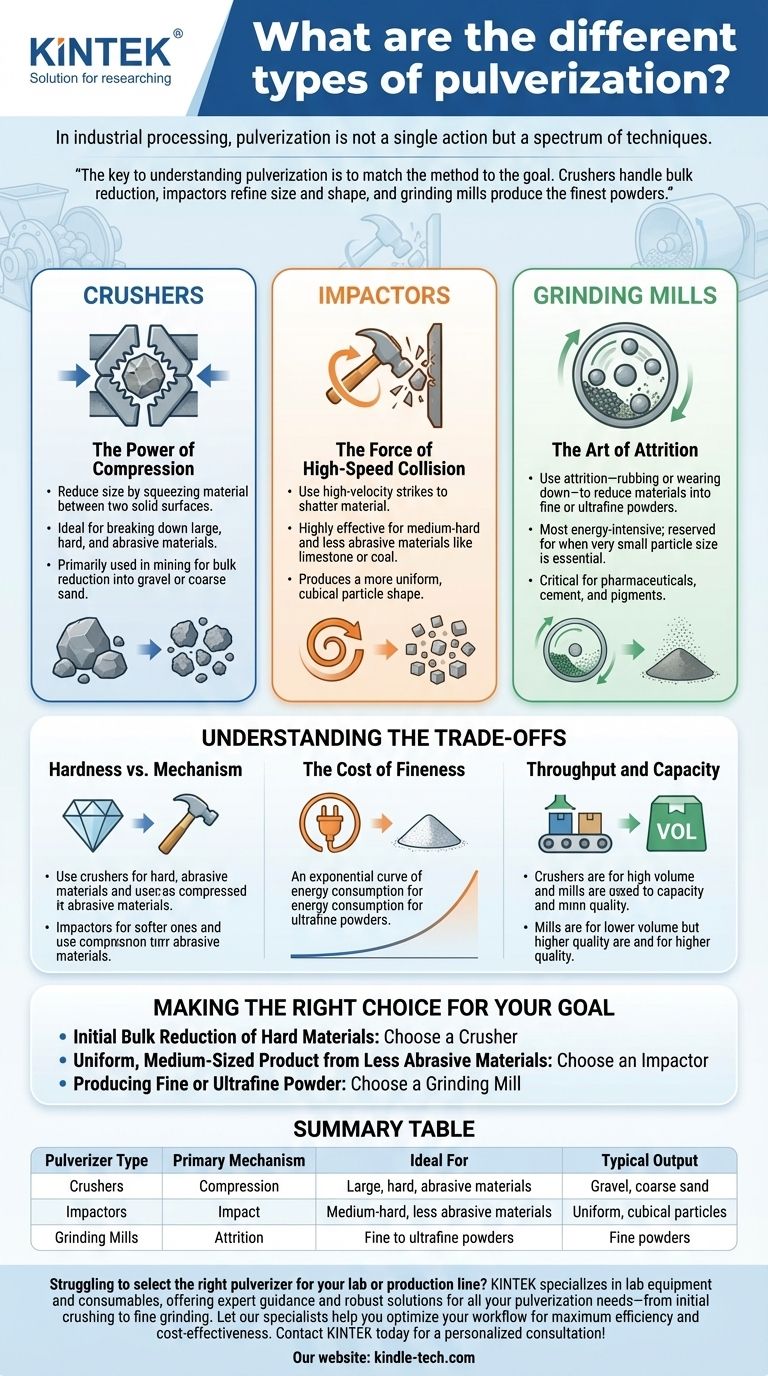

In industrial processing, pulverization is not a single action but a spectrum of techniques. The different types are best understood by the equipment used, as the machine's mechanism dictates the final particle size. The three primary categories of pulverizers are crushers, impactors, and grinding mills, each applying force in a distinct way to achieve a specific level of size reduction.

The key to understanding pulverization is to match the method to the goal. Crushers handle bulk reduction, impactors refine size and shape, and grinding mills produce the finest powders. The choice is a direct function of your starting material and your desired output.

The Three Core Pulverization Mechanisms

The fundamental difference between pulverizer types lies in how they apply force to break down a material. Each mechanism is optimized for a different stage of size reduction, from massive chunks down to microscopic powders.

Crushers: The Power of Compression

Crushers reduce size by squeezing material between two solid surfaces. This high-pressure compression is ideal for breaking down large, hard, and abrasive materials.

Think of a jaw crusher, which mimics a chewing motion. This method is the first step in many processes, often called primary or secondary crushing.

It is primarily used in mining and aggregate production to break down large rocks into more manageable gravel or coarse sand.

Impactors: The Force of High-Speed Collision

Impactors use high-velocity strikes to shatter material. This can happen when a spinning hammer strikes the material or when the material is thrown at high speed against a stationary surface.

This method is highly effective for medium-hard and less abrasive materials like limestone or coal.

Impactors often produce a more uniform, cubical particle shape compared to crushers, which can be a desirable trait in applications like concrete and asphalt production.

Grinding Mills: The Art of Attrition

Grinding mills use attrition—the act of rubbing or wearing down—to reduce materials into fine or ultrafine powders. This is achieved by tumbling the material with grinding media like steel balls or rods.

This is the most energy-intensive form of pulverization, reserved for when a very small particle size is essential.

Mills are critical in industries like cement manufacturing, pharmaceuticals, and pigment production, where the final product is a fine powder with specific physical properties.

Understanding the Trade-offs

Selecting a pulverizer is not just about the final size; it involves balancing material properties, energy costs, and throughput requirements. Understanding these trade-offs is crucial for an efficient operation.

Hardness vs. Mechanism

Hard, abrasive materials like granite or basalt will quickly wear down the hammers in an impactor. For these materials, a compression-based crusher is a more durable and cost-effective choice for initial reduction.

Softer, more friable materials are perfect for impactors, which can shatter them efficiently with less wear and tear.

The Cost of Fineness

There is a direct relationship between particle size and energy consumption. Achieving coarse reduction with a crusher is relatively energy-efficient.

However, producing an ultrafine powder with a grinding mill requires exponentially more energy per ton of material. The process of attrition is far less efficient than simple compression or impact.

Throughput and Capacity

Crushers are built for high throughput, processing hundreds or thousands of tons per hour in mining operations. Their purpose is bulk reduction.

Grinding mills, due to their energy demands and complex mechanics, typically have a much lower throughput. Their focus is on achieving a quality specification, not just volume.

Making the Right Choice for Your Goal

Your choice depends entirely on your starting material and your target particle size. By aligning the machine's mechanism with your operational goal, you can create the most effective and economical process.

- If your primary focus is initial bulk reduction of hard, abrasive materials: Your best choice is a crusher to efficiently create a manageable intermediate product.

- If your primary focus is creating a uniform, medium-sized product from less abrasive materials: An impactor offers an excellent balance of reduction and particle shape control.

- If your primary focus is producing a fine or ultrafine powder for advanced applications: A grinding mill is the necessary tool for achieving the required particle size through attrition.

Understanding these fundamental differences is the key to selecting the most efficient and cost-effective pulverization solution for your project.

Summary Table:

| Pulverizer Type | Primary Mechanism | Ideal For | Typical Output |

|---|---|---|---|

| Crushers | Compression (Squeezing) | Large, hard, abrasive materials (e.g., rocks) | Gravel, coarse sand |

| Impactors | Impact (High-speed collision) | Medium-hard, less abrasive materials (e.g., limestone) | Uniform, cubical particles |

| Grinding Mills | Attrition (Rubbing/grinding) | Fine to ultrafine powders (e.g., pharmaceuticals) | Fine powders |

Struggling to select the right pulverizer for your lab or production line? The efficiency of your process depends on matching the equipment to your material's properties and your target particle size. KINTEK specializes in lab equipment and consumables, offering expert guidance and robust solutions for all your pulverization needs—from initial crushing to fine grinding. Let our specialists help you optimize your workflow for maximum efficiency and cost-effectiveness. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis