At its core, pyrolysis is a process of thermal decomposition in an oxygen-free environment, and the reactor is the vessel where this transformation happens. The most common reactor types include fixed-bed, fluidized-bed, rotary kiln, and auger (or screw) reactors, but dozens of variations exist, each designed to optimize for specific outcomes. The key difference between them lies in how they transfer heat to the feedstock and how long they keep it at temperature.

The sheer number of reactor types can be overwhelming, but the choice is not about finding the single "best" reactor. It is about matching the reactor's specific design—its method of heating, material handling, and residence time—to the primary product you intend to create: bio-oil, biochar, or syngas.

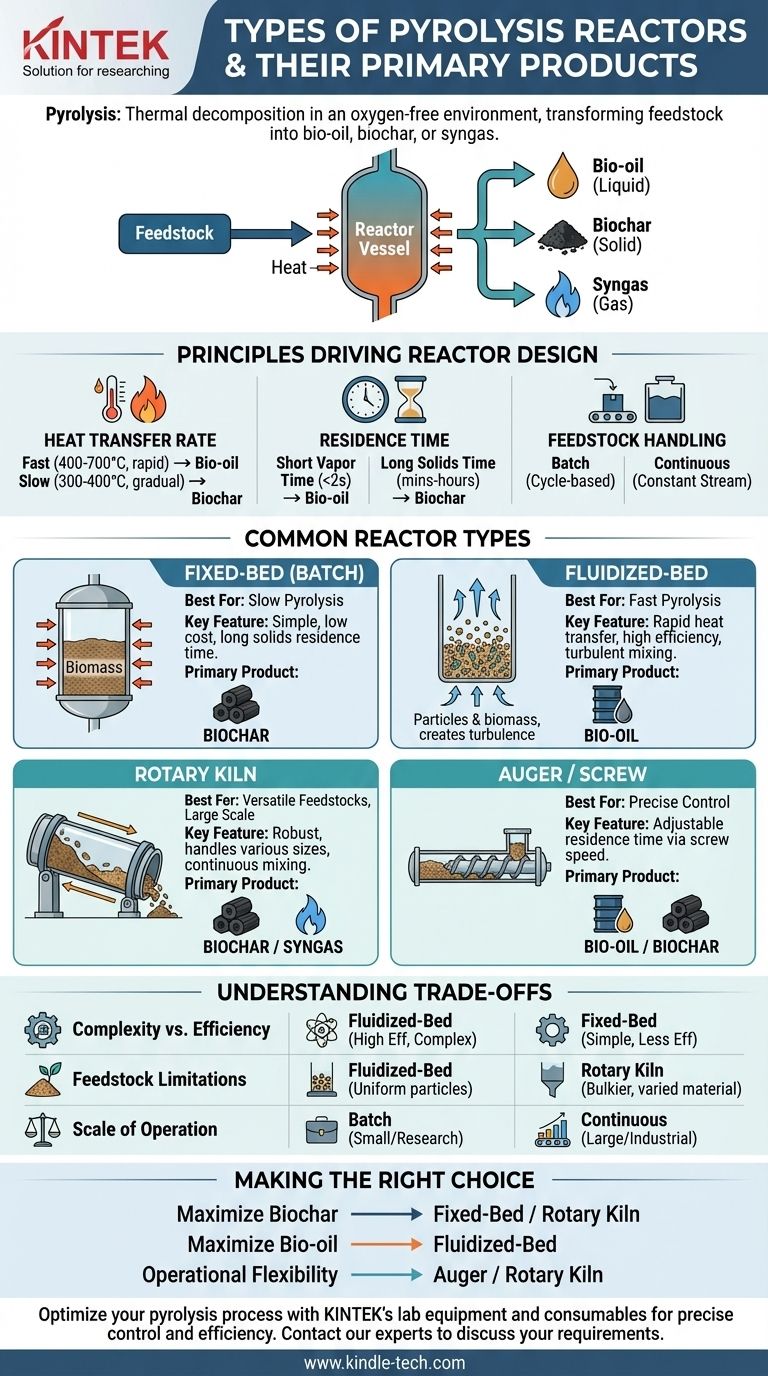

The Principles Driving Reactor Design

To understand the differences between reactors, you must first understand the variables they are built to control. A reactor's performance is defined by its ability to manage heat transfer, residence time, and feedstock movement.

Heat Transfer Rate: The Deciding Factor

The speed at which heat is transferred to the biomass is the most critical factor determining the final product mix.

Fast pyrolysis, which requires rapid heating to temperatures of 400-700°C, breaks down biomass into vapors that can be condensed into a liquid bio-oil. This process demands a reactor that can heat particles very quickly.

Slow pyrolysis, conversely, uses lower temperatures (300-400°C) and much slower heating rates. This environment favors the formation of a stable, solid carbon structure known as biochar.

Residence Time: How Long the Material Stays Hot

Residence time refers to the duration the biomass spends inside the hot zone of the reactor.

For fast pyrolysis, a very short vapor residence time (typically less than 2 seconds) is crucial to prevent the valuable vapors from further breaking down (cracking) into non-condensable gases.

For slow pyrolysis, a much longer solids residence time (from minutes to hours) is necessary to ensure the complete conversion of biomass into biochar.

Feedstock Handling: Batch vs. Continuous

Reactors can be classified by how they process material.

Batch reactors, like many fixed-bed designs, are loaded with a set amount of feedstock, sealed, and run through a complete cycle before being emptied. They are simple but less efficient for large-scale production.

Continuous reactors, such as fluidized-bed and auger systems, are fed a constant stream of feedstock and continuously discharge the products, allowing for uninterrupted industrial-scale operation.

A Closer Look at Common Reactor Types

With these principles in mind, the purpose of each major reactor type becomes clear. They are each engineered tools for achieving a specific set of process conditions.

Fixed-Bed and Batch Reactors (For Simplicity and Biochar)

These are often the simplest designs, where biomass is placed in a static "bed" within a container and heated from the outside.

Because heat must slowly penetrate a stationary mass, these reactors are inherently slow. This makes them ideal for slow pyrolysis where the primary goal is to maximize biochar yield. Their simple construction also means lower initial capital costs.

Fluidized-Bed Reactors (For High-Yield Bio-Oil)

In a fluidized-bed reactor, a hot gas (like nitrogen) is forced up through a bed of fine particles (such as sand), causing the biomass feedstock to become suspended and behave like a fluid.

This "fluidization" creates extremely turbulent mixing and exceptionally high heat transfer rates. This is the ideal condition for fast pyrolysis, making fluidized-bed reactors the industry standard for maximizing liquid bio-oil production.

Rotary Kiln Reactors (For Versatility and Scale)

A rotary kiln is a large, rotating cylinder that is slightly inclined. Feedstock is fed into the higher end and slowly tumbles toward the lower end as the kiln rotates.

The rotation constantly mixes the material, ensuring even heat distribution. While heat transfer is not as rapid as in a fluidized bed, these reactors are robust, can handle a wide variety of feedstock sizes and types, and are well-suited for large-scale slow or intermediate pyrolysis.

Auger and Screw Reactors (For Precise Control)

An auger reactor uses a large screw mechanism to actively push feedstock through a heated horizontal or vertical tube.

The key advantage here is precise control. The rotation speed of the screw directly dictates the residence time of the material in the heated zone. This high degree of control makes auger reactors very adaptable for different pyrolysis speeds and feedstocks.

Understanding the Trade-offs

No single reactor design is universally superior. The optimal choice always involves balancing competing factors based on your specific operational goals and constraints.

Complexity vs. Efficiency

Fluidized-bed reactors are highly efficient for producing bio-oil but are mechanically complex and sensitive to feedstock properties, requiring careful operational control. In contrast, fixed-bed reactors are simple and reliable but far less efficient for continuous processing.

Feedstock Limitations

The physical nature of your feedstock is a critical constraint. A fluidized-bed reactor requires uniformly sized, fine particles to function correctly. A rotary kiln, on the other hand, is much more forgiving and can process bulkier, less uniform materials like municipal solid waste or wood chips.

Scale of Operation

Batch reactors are suitable for small-scale or research applications. For high-throughput industrial production, continuous systems like circulating fluidized-beds, augers, or large rotary kilns are necessary to achieve economies of scale, despite their higher initial investment.

Making the Right Choice for Your Goal

Your choice of reactor should be a direct reflection of your primary objective.

- If your primary focus is maximizing biochar production: A slow pyrolysis process is required, for which simpler fixed-bed or robust rotary kiln reactors are the most effective tools.

- If your primary focus is maximizing liquid bio-oil yield: A fast pyrolysis process is essential, making high-efficiency fluidized-bed or ablative reactors the superior choice due to their rapid heat transfer capabilities.

- If your primary focus is operational flexibility and handling diverse feedstocks: Consider an auger (screw) reactor for its precise control over residence time or a rotary kiln for its unmatched robustness and material tolerance.

Ultimately, understanding that the reactor's design directly engineers the final product mix is the key to mastering pyrolysis technology.

Summary Table:

| Reactor Type | Best For | Key Feature | Primary Product |

|---|---|---|---|

| Fixed-Bed | Slow Pyrolysis | Simple, batch operation | Biochar |

| Fluidized-Bed | Fast Pyrolysis | Rapid heat transfer, high efficiency | Bio-oil |

| Rotary Kiln | Versatile Feedstocks | Robust, large-scale operation | Biochar / Syngas |

| Auger/Screw | Precise Control | Adjustable residence time | Bio-oil / Biochar |

Ready to optimize your pyrolysis process? The right reactor is critical for maximizing your yield of bio-oil, biochar, or syngas. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific pyrolysis needs. Whether you're scaling up from research or optimizing an industrial process, our expertise ensures you get the precise control and efficiency required for success. Contact our experts today to discuss how we can support your laboratory's pyrolysis reactor requirements and help you achieve superior results.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is coating deposition? Engineer Superior Surface Properties for Your Materials

- What are the advantages and disadvantages of fluidized bed systems? Unlock Superior Process Efficiency

- What is the energy consumption of conventional ultra-low temperature (ULT) freezers? Managing High Energy Costs

- What is the temperature at the bottom of the blast furnace? Unlocking the Heart of Iron Production

- What is titanium disadvantages and advantages? Weighing Performance vs. Cost for Your Project

- What features does the main access door of an Ultra Freezer have? Ensure Maximum Security and Thermal Stability

- How do you clean a sputtering target? Achieve Stable, High-Quality Thin-Film Deposition

- How do you test the purity of precious metals? From Acid Tests to Lab Analysis