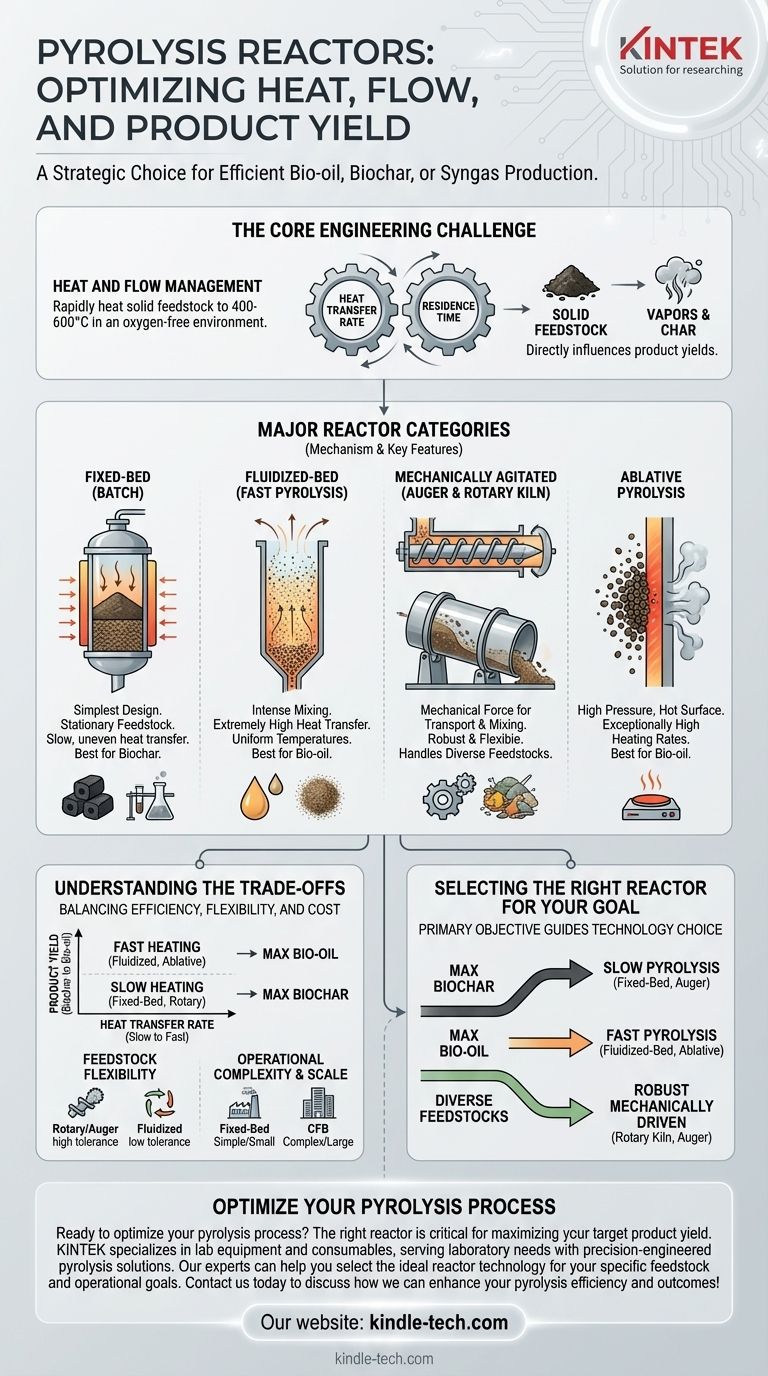

In pyrolysis, reactors are broadly categorized by how they heat the feedstock and manage material flow. While dozens of specific designs exist, the most common and commercially significant types include Fixed-Bed (or Batch), Fluidized-Bed, and mechanically agitated systems like Auger and Rotary Kiln reactors. Each is engineered to optimize for different feedstocks and target products, such as bio-oil, biochar, or syngas.

The choice of a pyrolysis reactor is not about finding a single "best" technology. It is a strategic decision that involves matching the reactor's heat transfer characteristics and material handling capabilities to your specific feedstock and desired end-product.

The Core Engineering Challenge: Heat and Flow

All pyrolysis reactors must solve the same fundamental problem: rapidly heat a solid feedstock to high temperatures (typically 400-600°C) in an oxygen-free environment. How a reactor accomplishes this dictates its performance.

The design directly influences the rate of heat transfer into the biomass particles and the residence time of solids and vapors inside the reactor. These two factors are the primary controls for the final product yields.

Major Reactor Categories Explained

Reactors are best understood by the mechanism they use to move and heat the material.

Fixed-Bed (Batch) Reactors

A fixed-bed reactor is the simplest design. The feedstock (the "bed") is loaded into a sealed vessel and heated from the outside. It remains stationary throughout the process.

This design is often used for smaller-scale or laboratory operations. Because the material is not agitated, heat transfer is slow and often uneven, leading to longer processing times.

Fluidized-Bed Reactors

In a fluidized-bed reactor, finely ground feedstock is "fluidized" by injecting a hot, inert gas from the bottom. The solid particles behave like a boiling liquid, mixing vigorously.

This intense mixing results in extremely high heat transfer rates and uniform temperatures. It is a form of fast pyrolysis, ideal for maximizing the production of liquid bio-oil. These systems require consistent, finely-milled feedstock to operate correctly.

Mechanically Agitated Reactors (Auger & Rotary Kiln)

These reactors use mechanical force to transport and mix the feedstock.

- An Auger Reactor (or screw reactor) uses a large, heated screw to push material through a horizontal or inclined tube.

- A Rotary Kiln is a large, rotating cylindrical drum set at a slight angle. As the kiln turns, the feedstock tumbles and moves from the higher end to the lower end.

Both designs are robust and can handle a wide variety of feedstock shapes, sizes, and moisture content, making them very flexible. Heat transfer is slower than in a fluidized bed but more controlled than in a fixed bed.

Ablative Pyrolysis Reactors

Ablative reactors take a unique approach. They press feedstock particles with high pressure against a rapidly moving hot surface. The material "ablates" or melts away layer by layer, producing vapors that are quickly removed.

This method achieves exceptionally high heating rates, also favoring bio-oil production. However, these systems can be mechanically complex and more sensitive to feedstock properties.

Understanding the Trade-offs

Choosing a reactor involves balancing efficiency, flexibility, and cost. No single design excels at everything.

Heat Transfer Rate vs. Product Yield

This is the most critical trade-off.

- Fast heating rates (Fluidized-Bed, Ablative) break down biomass structures quickly, preventing secondary reactions. This maximizes the yield of liquid bio-oil.

- Slow heating rates (Fixed-Bed, Rotary Kiln) allow for secondary cracking and repolymerization, which favors the formation of solid biochar.

Feedstock Flexibility

The reactor design dictates what kind of material you can process. Fluidized-bed reactors demand dry, finely ground, and uniform particles. In contrast, rotary kilns and auger reactors are far more tolerant of bulky, non-uniform, or higher-moisture feedstocks like plastic waste or agricultural residues.

Operational Complexity and Scale

A fixed-bed reactor is simple to build and operate but is not suited for continuous, large-scale industrial production. A Circulating Fluidized-Bed (CFB) system is highly efficient and scalable but represents a significant capital investment and requires sophisticated process controls.

Selecting the Right Reactor for Your Goal

Your primary objective should guide your choice of technology.

- If your primary focus is maximizing biochar production: Choose a slow pyrolysis system like a Fixed-Bed or Auger reactor that allows for longer residence times.

- If your primary focus is maximizing bio-oil yield: Choose a fast pyrolysis system like a Fluidized-Bed or Ablative reactor that provides rapid heat transfer.

- If your primary focus is processing diverse or difficult feedstocks: Choose a robust, mechanically driven system like a Rotary Kiln or Auger reactor known for its operational flexibility.

Understanding these core principles is the key to designing an effective and economically viable pyrolysis process.

Summary Table:

| Reactor Type | Best For | Key Characteristic |

|---|---|---|

| Fixed-Bed (Batch) | Maximizing Biochar, Small-Scale | Simple, slow heating, long residence time |

| Fluidized-Bed | Maximizing Bio-Oil (Fast Pyrolysis) | High heat transfer, uniform temperature, requires fine feedstock |

| Auger / Rotary Kiln | Processing Diverse Feedstocks | Mechanically agitated, robust, handles variable sizes/moisture |

| Ablative | Maximizing Bio-Oil | Extremely fast heating, mechanically complex |

Ready to optimize your pyrolysis process? The right reactor is critical for maximizing your target product yield—whether it's bio-oil, biochar, or syngas. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision-engineered pyrolysis solutions. Our experts can help you select the ideal reactor technology for your specific feedstock and operational goals. Contact us today to discuss how we can enhance your pyrolysis efficiency and outcomes!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy