While incredibly effective, the primary disadvantages of bead milling are the significant risk of product contamination from the grinding media, the complexity of process control, and the potential for product degradation due to intense heat generation. These challenges stem directly from the high-energy, high-contact nature of the milling process itself.

The core issue with bead milling isn't that it has flaws, but that its very mechanism—intense, high-frequency impacts—creates inherent risks. Successfully using a bead mill is less about avoiding these problems and more about actively managing the trade-offs between particle size reduction, purity, and process cost.

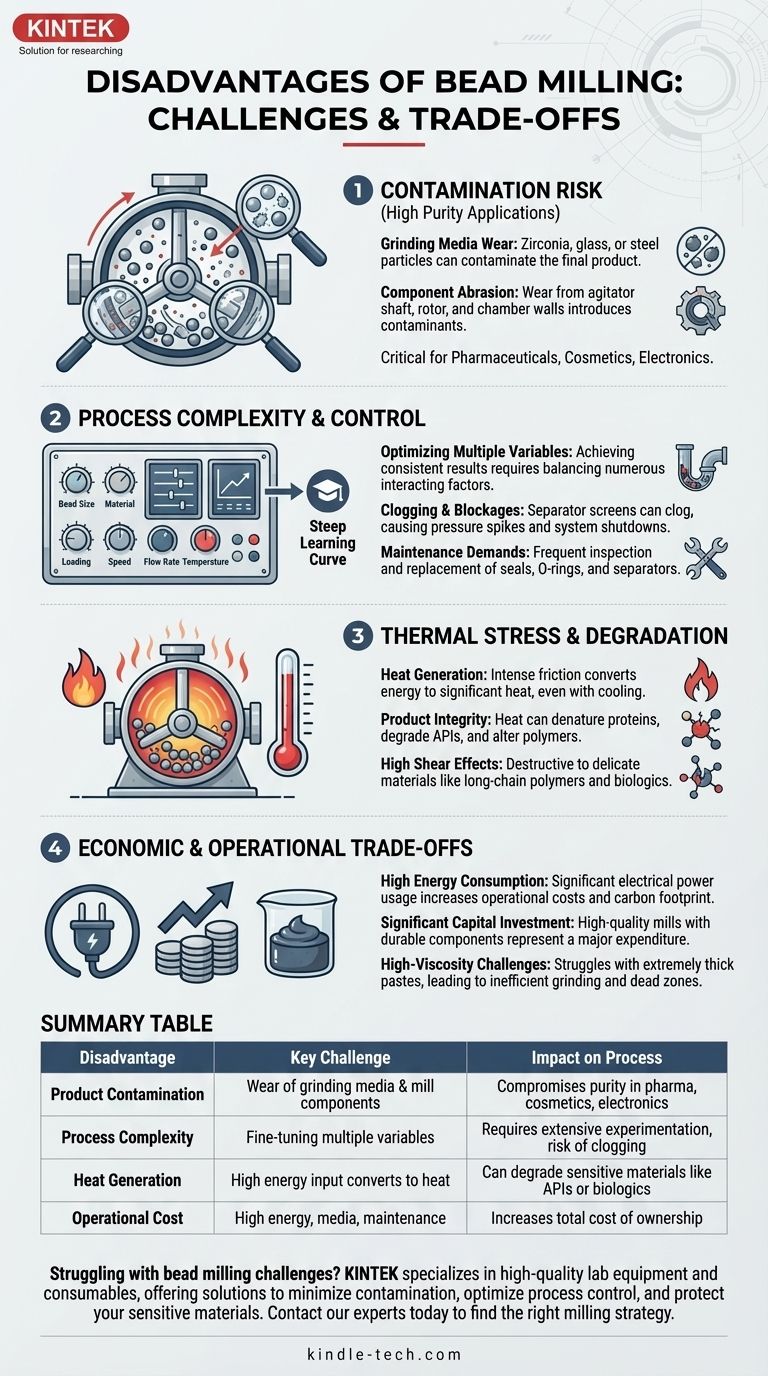

The Challenge of Contamination

Contamination is often the most critical concern, especially in high-purity applications like pharmaceuticals, cosmetics, and electronics. The contamination originates from the mechanical wear of the system's components.

Contamination from Grinding Media

The grinding beads are in constant, high-energy collision with each other, the chamber walls, and your product. This aggressive action inevitably causes the beads themselves to wear down.

Tiny particles of the bead material—whether it's zirconia, glass, or steel—will break off and mix into your final product. For an injectable drug or a semiconductor slurry, this is often unacceptable.

Contamination from Mill Components

It isn't just the beads that wear. The agitator shaft, rotor, and the internal chamber walls are also subject to abrasion.

This means particles from these components can also enter the product stream. Mitigating this requires using expensive, highly durable materials like ceramics or hardened alloys, which significantly increases the capital cost of the equipment.

Process Complexity and Control

A bead mill is not a simple "set it and forget it" device. Achieving consistent, repeatable results requires fine-tuning a complex interplay of variables, which can be a steep learning curve.

Optimizing Multiple Variables

Success depends on balancing bead size, bead material, bead loading (the fill volume), agitator speed, product flow rate, and temperature. An incorrect combination can lead to inefficient grinding, excessive wear, or even damage to the product.

Finding the optimal "recipe" for a specific formulation often requires extensive experimentation and process development, adding time and cost to a project.

The Risk of Clogging and Blockages

Bead mills use a separator, typically a screen or gap, to keep the beads inside the milling chamber while allowing the product slurry to exit.

This separator can become clogged by oversized particles or an agglomerating product. A blockage causes a rapid pressure increase, forcing a system shutdown and requiring time-consuming cleaning and maintenance.

Demanding Maintenance Requirements

The high-wear environment means that components like mechanical seals, O-rings, and the bead separator require frequent inspection and replacement. Failure to do so can lead to leaks, loss of expensive product, and significant downtime.

Product Integrity and Thermal Stress

The energy required to break down particles doesn't just disappear; much of it is converted into heat. This thermal stress can be just as damaging as contamination.

Heat Generation and Product Degradation

The intense friction within the milling chamber generates a substantial amount of heat. Even with efficient cooling jackets, the temperature can rise significantly.

This heat can denature proteins, degrade active pharmaceutical ingredients (APIs), alter the properties of polymers, or cause unwanted chemical reactions in your formulation. Managing temperature is a critical, and sometimes limiting, factor.

High Shear Stress Effects

While high shear is necessary for particle size reduction, it can be destructive to certain materials. Delicate structures like long-chain polymers or certain biologics can be unintentionally broken apart, fundamentally changing the nature of the product.

Understanding the Economic and Operational Trade-offs

Beyond the technical challenges, bead milling carries significant economic and operational considerations that must be factored into any decision.

High Energy Consumption

Bead mills are powerful machines that require significant electrical energy to operate, especially at industrial scales. This translates directly to higher operational costs and a larger carbon footprint compared to lower-energy mixing methods.

Significant Capital Investment

High-quality bead mills are expensive. Models designed to minimize contamination with ceramic-lined chambers and precision components represent a major capital expenditure. The grinding media itself can also be a considerable recurring cost.

Challenges with High-Viscosity Materials

While bead mills handle a wide range of viscosities, they can struggle with extremely thick pastes. In these cases, the media may not circulate effectively, leading to "dead zones" in the chamber and highly inefficient grinding, making other technologies like three-roll mills a better choice.

Making the Right Choice for Your Goal

Understanding these disadvantages is key to mitigating them. Your strategy will depend entirely on your primary objective.

- If your primary focus is ultimate purity (e.g., pharma, electronics): You must invest in high-grade ceramic media and mill components and rigorously validate your cleaning and testing protocols to manage contamination risk.

- If your primary focus is cost-sensitive bulk production (e.g., inks, coatings): Your key challenge is balancing media cost against wear rate and energy consumption, as these will be your largest operational expenses.

- If your primary focus is processing heat-sensitive materials (e.g., biologics): Prioritize a mill with a highly efficient cooling system and precise temperature control, and be prepared to operate at slower, less aggressive parameters.

By anticipating these challenges, you can properly design your process, select the right equipment, and harness the power of bead milling effectively.

Summary Table:

| Disadvantage | Key Challenge | Impact on Process |

|---|---|---|

| Product Contamination | Wear of grinding media & mill components | Compromises purity in pharma, cosmetics, electronics |

| Process Complexity | Fine-tuning multiple variables (speed, bead size, flow rate) | Requires extensive experimentation, risk of clogging |

| Heat Generation | High energy input converts to heat, even with cooling | Can degrade sensitive materials like APIs or biologics |

| Operational Cost | High energy consumption, expensive media, frequent maintenance | Increases total cost of ownership for lab & production |

Struggling with bead milling challenges in your lab? KINTEK specializes in high-quality lab equipment and consumables, offering solutions to minimize contamination, optimize process control, and protect your sensitive materials. Contact our experts today to find the right milling strategy for your pharmaceutical, cosmetic, or R&D needs!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What is the function of vacuum milling in Ti2AlN synthesis? Ensure High Purity & Superior Ceramic Quality

- Can I use wet grinder for dry grinding? Avoid Damaging Your Kitchen Appliance

- Does milling reduce particle size? Achieve Precise Control Over Your Material's Properties

- What size is a ball mill crushing? Understanding Its Role as a Grinding Tool, Not a Crusher

- What is a roller mill used for in the pharmaceutical industry? A Key Tool for Dry Granulation

- What is the role of a ball milling system in the physical synthesis of wüstite nanoparticles? Key Mechanisms Explained

- What is the role of a 3-dimensional mixer in glass raw material pretreatment? Enhance Chemical Consistency

- What is the critical role of high-energy ball mills in UHTC powders? Enhancing Sintering Efficiency and Reactivity