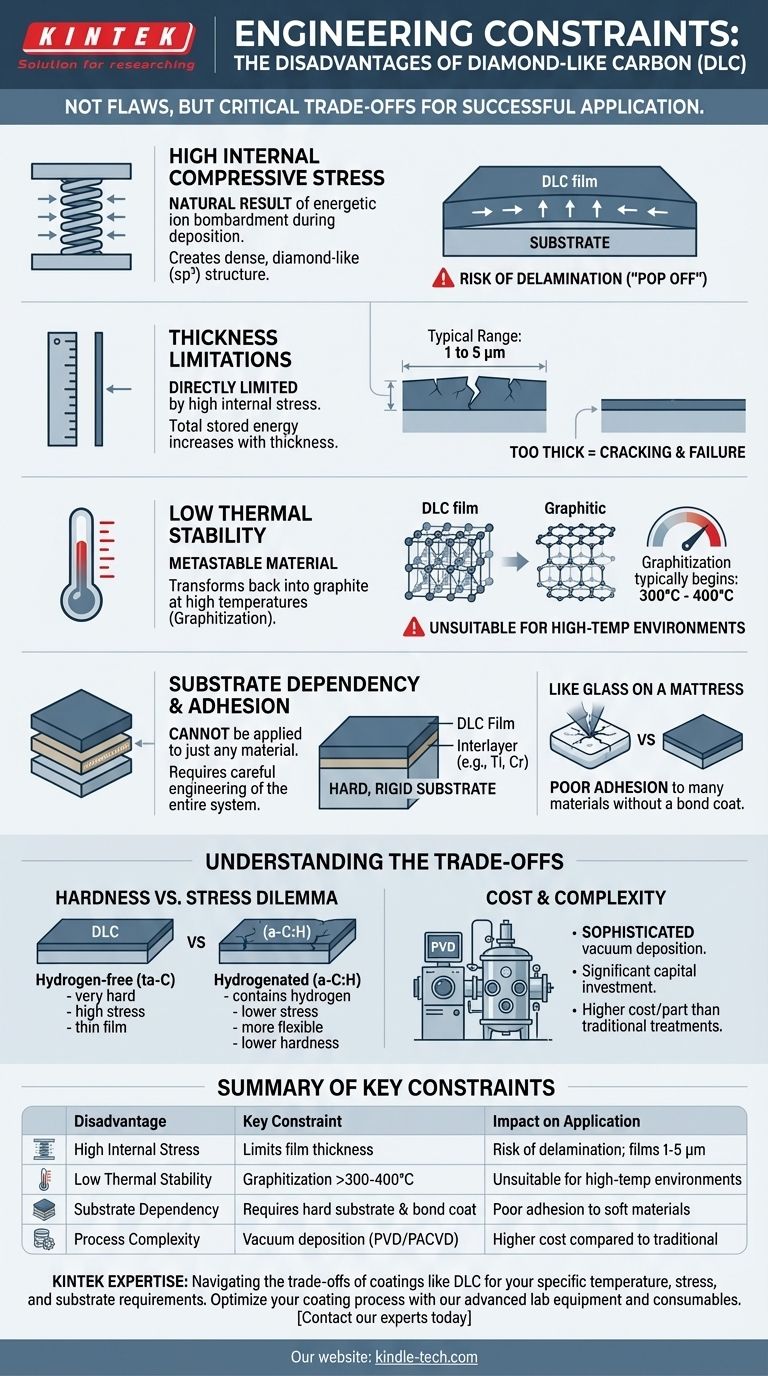

While often celebrated for its exceptional properties, diamond-like carbon (DLC) is not a universal solution for all wear and friction problems. Its primary disadvantages stem from high internal compressive stress which limits film thickness, poor thermal stability that restricts its use to lower-temperature environments, and a strong dependency on the substrate material and preparation for proper adhesion. These are not flaws, but critical engineering constraints that must be understood for successful application.

The "disadvantages" of DLC are better understood as engineering trade-offs. Its remarkable hardness and low friction come at the cost of constraints in application temperature, film thickness, and substrate compatibility, making the success of a DLC coating highly dependent on a correctly engineered system.

The Primary Engineering Constraints of DLC Coatings

The limitations of DLC are intrinsically linked to its unique amorphous structure and the vacuum deposition processes used to create it. Understanding these constraints is the key to avoiding application failures.

High Internal Compressive Stress

Nearly all DLC films are grown with a significant amount of internal compressive stress. This is a natural result of the energetic ion bombardment used during deposition to create the dense, diamond-like (sp³) structure.

While some stress is beneficial for hardness, excessive stress is the root cause of other limitations. If the stress exceeds the coating's adhesion strength to the substrate, it can spontaneously delaminate or "pop off".

Thickness Limitations

The high internal stress directly limits the practical thickness of DLC coatings. As the film gets thicker, the total stored energy from stress increases.

Most functional DLC coatings are therefore very thin, typically ranging from 1 to 5 micrometers (μm). Attempting to deposit thicker films often results in catastrophic failure due to cracking and poor adhesion.

Low Thermal Stability

DLC is a metastable material, meaning it is not in its most chemically stable state (which is graphite). When heated, it will begin to transform back into graphite, losing its hardness and low-friction properties.

This transformation, known as graphitization, typically begins at temperatures between 300°C and 400°C. This makes standard DLC unsuitable for high-temperature applications like cutting tools for dry high-speed machining or components in exhaust systems.

Substrate Dependency and Adhesion

DLC coatings cannot be applied to just any material. Successful application requires careful engineering of the entire system, starting with the substrate.

The substrate must be sufficiently hard and rigid to support the thin, hard DLC film under load. Applying DLC to a soft substrate is like putting a sheet of glass on a mattress—it will simply fracture under pressure.

Furthermore, direct adhesion of DLC to many materials, especially steel, is poor. A metallic interlayer or "bond coat" (such as chromium or titanium) is almost always required to manage stress and ensure the DLC film sticks properly.

Understanding the Trade-offs

Choosing a DLC coating involves navigating a series of well-understood trade-offs. The "best" DLC is entirely dependent on the specific goal of the application.

The Hardness vs. Stress Dilemma

There are many types of DLC, but they can be broadly categorized by the presence of hydrogen.

Hydrogen-free DLC (ta-C) is the hardest and most diamond-like type, but it also possesses the highest internal compressive stress. This makes it more difficult to apply and limits it to thinner films.

Hydrogenated DLC (a-C:H) contains hydrogen, which helps to relieve some of the internal stress. This makes the coating more flexible and easier to apply in thicker layers, but it comes at the cost of reduced hardness and wear resistance compared to ta-C.

Cost and Process Complexity

Applying DLC is not a simple dipping or spraying process. It requires sophisticated vacuum deposition equipment (PVD or PACVD), which represents a significant capital investment.

The process itself is complex, requiring precise control over vacuum levels, process gases, and plasma energy. This translates to a higher cost per part compared to traditional surface treatments like nitriding or hard chrome plating.

Making the Right Choice for Your Application

To determine if DLC is the right solution, you must weigh its advantages against its practical limitations for your specific operating conditions.

- If your primary focus is extreme wear resistance at low temperatures: Non-hydrogenated ta-C is likely the best choice, but you must use a hard, rigid substrate and a properly engineered adhesion layer.

- If your primary focus is low friction and good general wear: Hydrogenated a-C:H offers a more cost-effective and process-flexible solution with lower stress, making it suitable for a wider range of components.

- If your application involves temperatures above 350°C or high impact loads: DLC is likely the wrong choice, and you should investigate alternative ceramic coatings (like TiN, AlTiN) or diffusion treatments like nitriding.

Ultimately, successfully leveraging DLC comes from treating it not as a magic coating, but as a high-performance material whose constraints must be respected and engineered around.

Summary Table:

| Disadvantage | Key Constraint | Impact on Application |

|---|---|---|

| High Internal Stress | Limits film thickness | Risk of delamination; films typically 1-5 μm |

| Low Thermal Stability | Graphitization above 300-400°C | Unsuitable for high-temperature environments |

| Substrate Dependency | Requires hard, rigid substrate & bond coat | Poor adhesion to soft materials like steel |

| Process Complexity | Requires vacuum deposition (PVD/PACVD) | Higher cost compared to traditional treatments |

Struggling with wear, friction, or coating failures? KINTEK specializes in advanced lab equipment and consumables for material surface engineering. Our expertise helps you navigate the trade-offs of coatings like DLC, ensuring you select the right solution for your specific temperature, stress, and substrate requirements. Contact our experts today to optimize your coating process and enhance component performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- How are wafers and electrodes configured within a PECVD system? Mastering Parallel-Plate Architecture

- What is the material for DLC? A Guide to Tunable Diamond-Like Carbon Coatings

- What are the properties of silicon dioxide film deposited by PECVD at low temperature pressure? Achieve Superior Insulation on Sensitive Substrates

- What are the typical operating pressures and temperatures for PECVD systems? Expert Guide to Optimal Parameters

- What is plasma assisted deposition process? Enable Low-Temperature, High-Quality Thin Films

- What precursor gases are used to form silicon dioxide and silicon nitride films via PECVD? Expert Precursor Guide

- What is the principle of PECVD? Harness Low-Temperature Plasma for Superior Thin Film Deposition

- What are the key features of high-capacity tubular PECVD equipment? Maximize Throughput for Silicon Cell Manufacturing