To be direct, the primary disadvantages of flash pyrolysis oil stem from its undesirable chemical properties. Specifically, its high water content, inherent instability over time, and the potential for harmful emissions during production make it a challenging resource to handle and utilize effectively.

While flash pyrolysis presents a compelling pathway to convert biomass into liquid fuel, the resulting bio-oil is not a "drop-in" replacement for conventional petroleum. Its reactive and unstable nature means it requires significant upgrading or specialized equipment to overcome fundamental challenges in storage, transport, and final application.

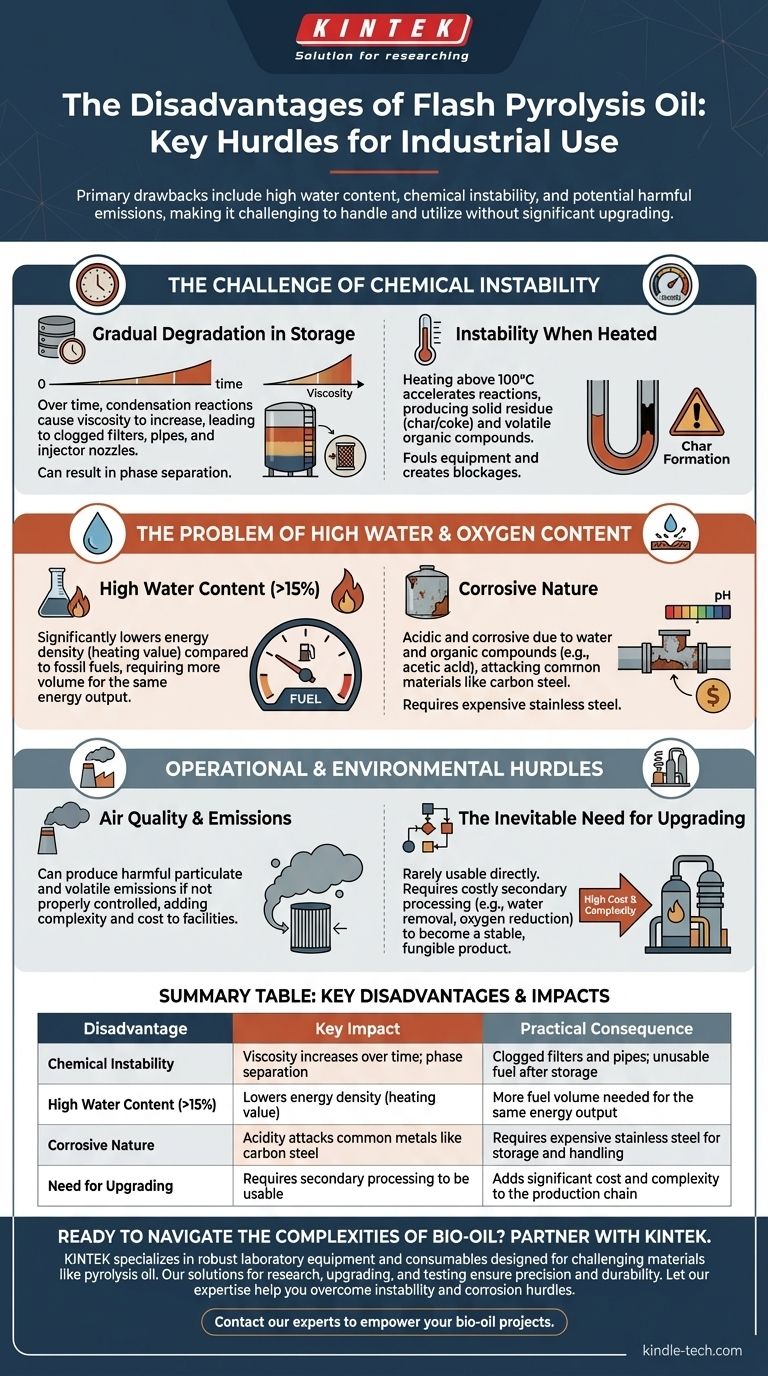

The Challenge of Chemical Instability

The most significant operational drawback of pyrolysis oil is its tendency to change over time. It is a mixture of reactive compounds, not a stable final product.

Gradual Degradation in Storage

Pyrolysis oil is not stable for long-term storage. Over weeks and months, condensation reactions between its organic molecules cause a gradual increase in viscosity.

This thickening can clog filters, pipes, and injector nozzles. In some cases, the oil can even undergo phase separation, splitting into distinct layers that make it an inconsistent and unusable fuel source.

Instability When Heated

The oil's instability is accelerated by heat. Heating the oil above 100°C can trigger rapid reactions that produce solid residue (char or coke) and volatile organic compounds.

This severely limits its use in applications that require preheating, such as conventional boilers or refinery processes, as it will foul equipment and create blockages.

The Problem of High Water and Oxygen Content

Unlike petroleum crude, flash pyrolysis oil contains significant amounts of water and oxygen, which degrade its quality as a fuel.

High Water Content

Flash pyrolysis oil typically has a high water content, often exceeding 15% by weight. This water is produced during the pyrolysis reaction and is intimately mixed within the oil.

Because water does not combust, its presence significantly lowers the energy density (heating value) of the oil compared to fossil fuels, meaning more volume is required to produce the same amount of energy.

Corrosive Nature

The combination of high water content and oxygenated organic compounds (like acetic acid) makes raw pyrolysis oil acidic and corrosive to common construction materials like carbon steel.

This necessitates the use of more expensive, corrosion-resistant stainless steel for storage tanks, pumps, and piping, increasing infrastructure costs.

Understanding the Operational and Environmental Hurdles

Beyond the oil's chemistry, the production process itself presents challenges that must be carefully managed.

Air Quality and Emissions

The pyrolysis process can produce harmful emissions if not properly controlled. The furnace and related equipment must be well-designed and maintained to minimize the release of particulates and volatile compounds.

Achieving environmentally compliant operation adds a layer of technical complexity and cost to any pyrolysis facility.

The Inevitable Need for Upgrading

Collectively, these disadvantages mean that pyrolysis oil can rarely be used directly. To become a viable, fungible product, it must undergo costly secondary processing or "upgrading."

Upgrading processes aim to remove water, reduce oxygen, and stabilize the molecules, but they add significant expense and energy penalties to the overall production chain.

How to Apply This to Your Project

Understanding these limitations is critical for evaluating the feasibility of using flash pyrolysis oil in any context.

- If your primary focus is direct combustion for heat or power: You must use specialized boilers and burners designed to handle high-viscosity, corrosive, and low-energy-density fuels.

- If your primary focus is long-term storage or transport: Instability is your main barrier, requiring controlled conditions or immediate on-site processing to prevent degradation.

- If your primary focus is refining into transportation fuels or chemicals: Extensive and costly upgrading is non-negotiable to remove water and oxygen and create stable molecules suitable for a refinery.

Ultimately, successfully integrating flash pyrolysis oil requires treating it as a unique intermediate chemical product, not as a direct substitute for crude oil.

Summary Table:

| Disadvantage | Key Impact | Practical Consequence |

|---|---|---|

| Chemical Instability | Viscosity increases over time; phase separation | Clogged filters and pipes; unusable fuel after storage |

| High Water Content (>15%) | Lowers energy density (heating value) | More fuel volume needed for the same energy output |

| Corrosive Nature | Acidity attacks common metals like carbon steel | Requires expensive stainless steel for storage and handling |

| Need for Upgrading | Requires secondary processing to be usable | Adds significant cost and complexity to the production chain |

Ready to Navigate the Complexities of Bio-Oil? Partner with KINTEK.

Integrating flash pyrolysis oil into your operations requires specialized knowledge and equipment. KINTEK specializes in providing robust laboratory equipment and consumables designed to handle challenging materials like pyrolysis oil. Whether you are researching upgrading processes, testing material compatibility, or optimizing combustion, our solutions are built for precision and durability.

We understand the unique demands of biomass conversion and are here to support your R&D and quality control needs. Let our expertise help you overcome the hurdles of chemical instability and corrosion.

Contact our experts today to discuss how KINTEK's lab equipment can empower your bio-oil projects and drive your innovation forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the procedure for pyrolysis? Turn Waste into Fuel, Char, and Gas

- What is a pyrolysis reactor? A Guide to Converting Waste into Valuable Resources

- What is the purpose of plastic pyrolysis? Convert Waste Plastic into Valuable Resources

- What is the heat required for calcination? A Guide to Accurate Energy Calculations

- What waste is suitable for pyrolysis? Unlock Value from Plastics, Biomass, and Tires

- What are the disadvantages of a rotary furnace? Key Limitations in Maintenance and Material Handling

- What is a rotary retort furnace? Achieve Superior Uniformity in Continuous Heat Treatment

- What is the process of rotary calciner? Achieve Uniform Thermal Treatment for Bulk Solids