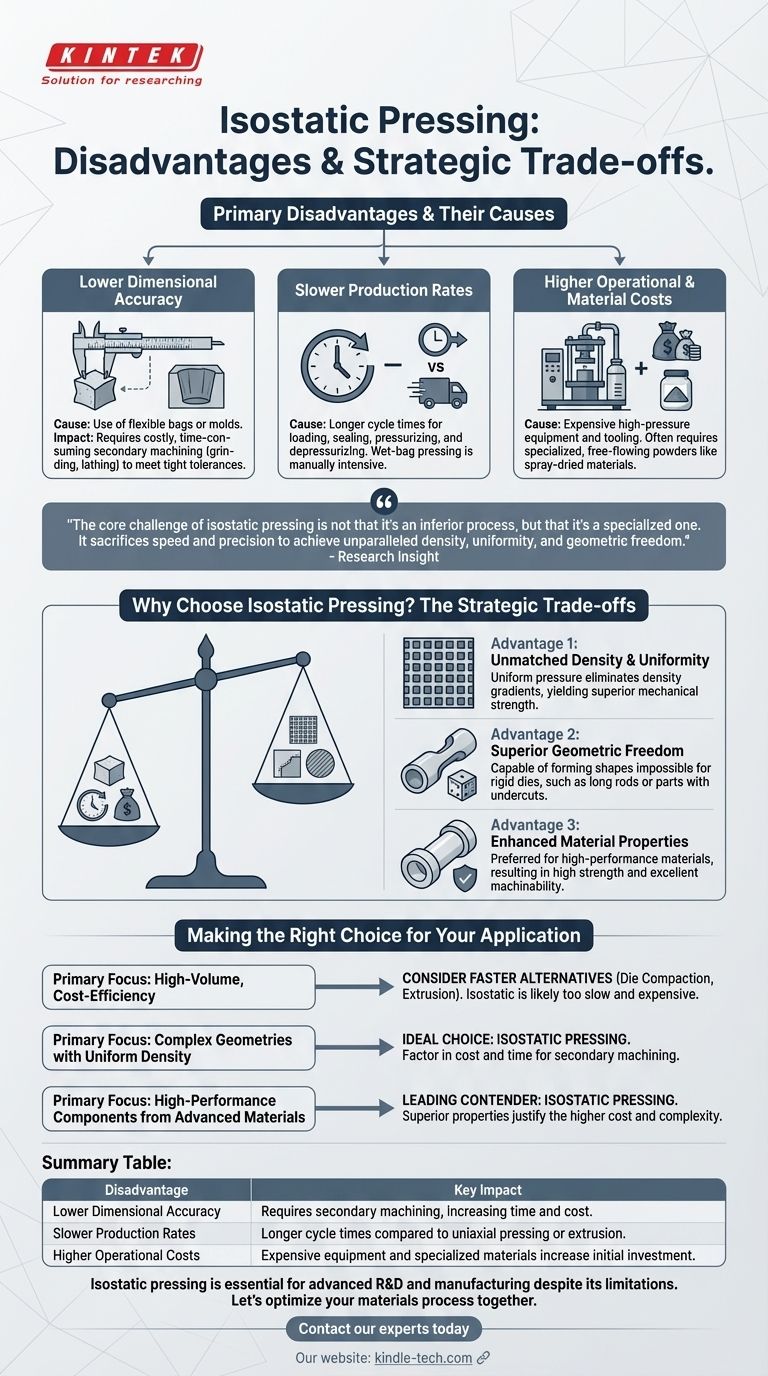

The primary disadvantages of isostatic pressing center on its lower dimensional accuracy, slower production speed, and higher operational costs when compared to other compaction methods. These limitations stem directly from the use of a flexible mold and high-pressure fluid to compact the powder, which necessitates trade-offs between geometric complexity and manufacturing efficiency.

The core challenge of isostatic pressing is not that it's an inferior process, but that it's a specialized one. It sacrifices speed and precision to achieve unparalleled density, uniformity, and geometric freedom that are impossible with conventional methods.

The Core Limitations Explained

To determine if isostatic pressing is suitable for your application, it's essential to understand the "why" behind each of its disadvantages. These are not flaws in the technology but inherent characteristics of the process.

Lower Dimensional Accuracy

The use of a flexible bag or mold means that the surfaces of the compacted part are not as precise as those formed by a rigid steel die. This is the most significant drawback.

This lack of precision often requires secondary machining (such as grinding or lathing) to meet tight dimensional tolerances. This additional step adds both time and cost to the overall manufacturing workflow.

Slower Production Rates

Compared to high-speed methods like uniaxial (die) compaction or extrusion, isostatic pressing is a considerably slower process.

The cycle time is longer due to the need to load the powder into the mold, seal the vessel, pressurize the system, and then safely de-pressurize and unload the part. Wet-bag pressing, in particular, has lower productivity due to the manual loading and unloading of molds from the pressure vessel.

Higher Operational & Material Costs

The equipment for isostatic pressing, which must handle extremely high pressures safely, is inherently more complex and expensive. This leads to higher initial tooling costs.

Furthermore, fully automatic dry-bag presses often require a specialized, free-flowing powder, such as spray-dried powder, which is more expensive than standard raw material powders.

Understanding the Trade-offs: Why Choose Isostatic Pressing?

Acknowledging these disadvantages is critical, but they only tell half the story. Engineers choose isostatic pressing when the benefits decisively outweigh the drawbacks for a specific application.

Unmatched Density and Uniformity

The defining advantage of isostatic pressing is its ability to apply pressure equally from all directions. This results in a final part with extremely high and uniform density.

This uniformity eliminates the density gradients and internal stresses common in uniaxial pressing, leading to superior mechanical strength and predictable shrinkage during sintering.

Superior Geometric Freedom

Because the powder is compacted by fluid pressure against a flexible mold, the process can form shapes that are impossible for rigid dies. This includes parts with high length-to-diameter ratios (long rods or tubes) or complex undercuts.

This capability is essential for manufacturing components like ceramic insulator tubes or specialized alloy preforms that cannot be produced effectively with other methods.

Enhanced Material Properties

The uniform compaction leads to products with high strength and excellent machinability. It is a preferred method for forming high-performance components from advanced materials like zirconia and alumina ceramics or new alloys that are difficult to cast.

Making the Right Choice for Your Application

Selecting the correct manufacturing process requires aligning the technology's characteristics with your project's primary goals.

- If your primary focus is high-volume production and cost-efficiency: You should evaluate faster alternatives like die compaction or extrusion, as isostatic pressing will likely be too slow and expensive.

- If your primary focus is creating complex geometries with uniform density: Isostatic pressing is the ideal choice, but you must factor the cost and time for secondary machining into your plan.

- If your primary focus is developing high-performance components from advanced materials: Isostatic pressing is a leading contender, offering superior material properties that justify its higher cost and complexity.

Ultimately, understanding these limitations is the key to leveraging the unique strengths of isostatic pressing for the right applications.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Lower Dimensional Accuracy | Requires secondary machining, increasing time and cost. |

| Slower Production Rates | Longer cycle times compared to uniaxial pressing or extrusion. |

| Higher Operational Costs | Expensive equipment and specialized materials increase initial investment. |

Is isostatic pressing the right choice for your lab's high-performance materials?

While isostatic pressing has specific limitations, its ability to produce parts with unparalleled density and complex geometries is essential for advanced R&D and manufacturing. KINTEK specializes in providing the precise lab equipment and consumables you need to navigate these process trade-offs effectively.

Let's optimize your materials process together. Contact our experts today to discuss how isostatic pressing or alternative solutions can achieve your project goals for strength, uniformity, and geometric freedom.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components