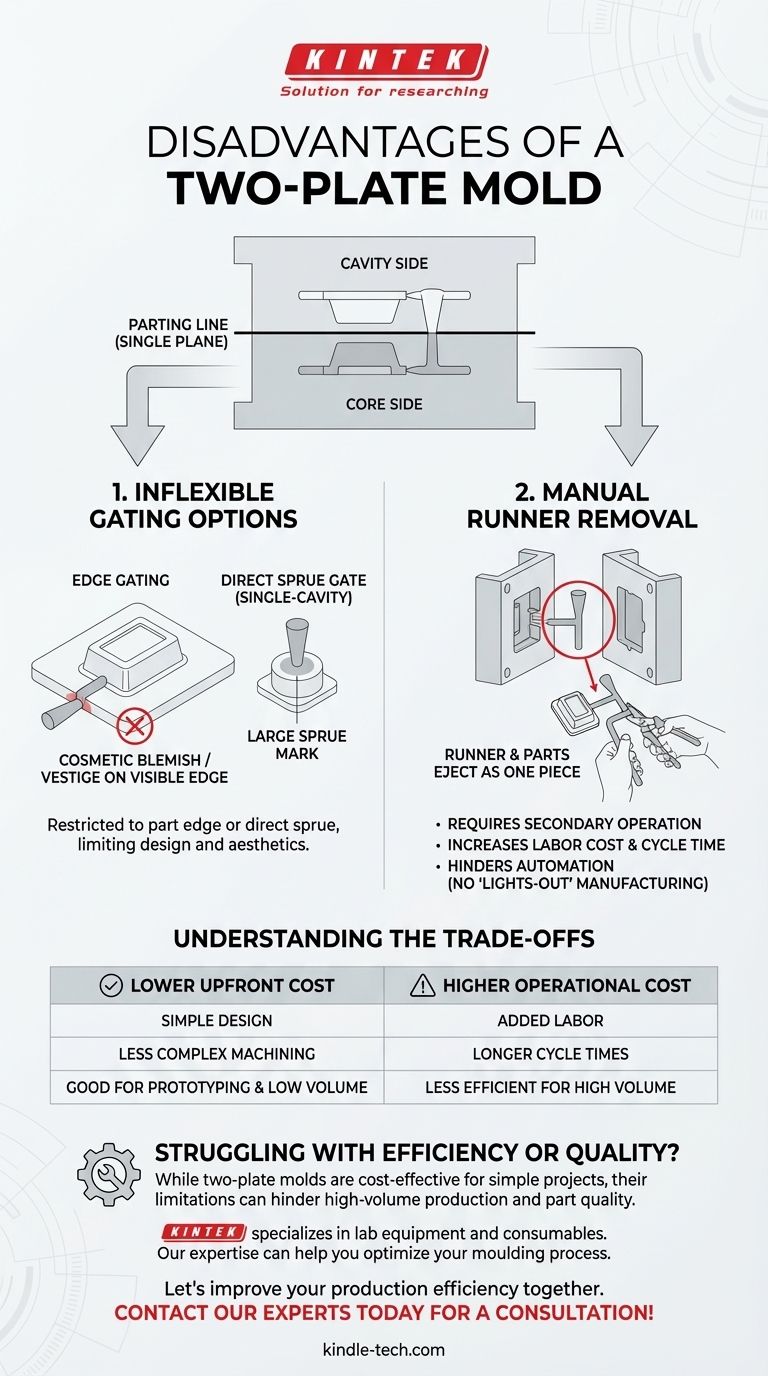

The primary disadvantages of a two-plate mold are its inflexible gating options and the need for manual runner removal after molding. Because of its simple construction with a single parting line, the gate—where plastic enters the part cavity—is almost always restricted to the edge of the component. This also means the runner system remains attached to the parts upon ejection, requiring a secondary, often manual, step to separate them.

While valued for its simplicity and lower initial cost, the two-plate mold's core disadvantages stem from a single source: its design forces both the part and the runner system to exist on the same plane, which creates downstream inefficiencies and design limitations.

The Core Limitation: A Single Parting Line

To understand the disadvantages, we must first understand the fundamental structure of a two-plate mold. Its simplicity is both its greatest strength and the source of its limitations.

What is a Two-Plate Mold?

A two-plate mold is the most basic type of injection mold. It consists of two main halves, a cavity side and a core side, which meet at a single plane known as the parting line.

The Consequence of a Single Plane

When the mold opens, it separates only at this one parting line. This means that the parts themselves and the entire feed system (the sprue and runners that deliver the plastic) must be located on this plane to be ejected. This structural constraint is the root cause of its main drawbacks.

Disadvantage 1: Inflexible Gating Options

The single parting line severely restricts where and how molten plastic can be injected into the part cavity.

Why Gates Are Limited to the Part Edge

Because the runner system must lie on the parting line, it can only connect to the part where the part also meets that line. In nearly all cases, this is the outer edge or perimeter of the component. This is known as edge gating or side gating.

The Problem with Edge Gating

Forcing the gate to the side of the part can be a significant issue. It leaves a cosmetic blemish, or vestige, at the separation point, which may be unacceptable for visible surfaces. It can also lead to non-ideal plastic flow patterns in complex parts, potentially causing defects.

The Exception: Direct Gating

A single-cavity two-plate mold can utilize a direct sprue gate, where the sprue feeds plastic directly into the center of the part. However, this leaves a very large, often cosmetically poor, mark and is only suitable for specific part geometries where such a blemish is hidden or unimportant.

Disadvantage 2: Manual Runner Removal

The second major drawback is a direct consequence of the feed system being attached to the parts.

The Runner Stays Attached

When the molding cycle is complete and the mold opens, the hardened runner system and the finished parts are pushed out as a single, connected piece of plastic.

The Cost of Secondary Operations

This unified piece requires a secondary operation to separate the runners from the parts. This is often done manually by a machine operator, which adds labor cost and increases the overall cycle time for each shot.

Automation Challenges

The need for manual separation makes it difficult to implement a fully automated "lights-out" manufacturing process. This inefficiency makes two-plate molds less suitable for very high-volume production where every second of cycle time counts.

Understanding the Trade-offs

The disadvantages of a two-plate mold must be weighed against its primary advantage: cost-effectiveness.

Lower Initial Tooling Cost

Two-plate molds are simpler in design and require less complex machining. This results in a lower upfront cost to build the tool, making them an excellent choice for projects with tight budgets.

Higher Long-Term Operational Cost

The initial savings can be offset over time by higher operational costs. The added labor for de-gating and the longer cycle times can make the price-per-part higher than that of more complex molds, especially in high-volume runs.

When Simplicity is the Right Choice

Despite the limitations, a two-plate mold is often the perfect solution for prototyping, low-volume production runs, or for parts where an edge gate is cosmetically and structurally acceptable.

Making the Right Choice for Your Project

Choosing the correct mold type requires aligning the tool's capabilities with your project's specific goals.

- If your primary focus is minimizing upfront tool cost and production volume is low: A two-plate mold is almost always the most economical and practical choice.

- If your primary focus is part cosmetics and hiding gate marks: You will need to consider a three-plate or hot runner mold, as a two-plate design forces the gate to the part's visible edge.

- If your primary focus is high-volume, automated production: The manual runner removal required by a two-plate mold will increase cycle time and labor costs, making a more advanced mold design far more efficient.

Ultimately, understanding these fundamental limitations allows you to balance tooling investment with long-term production efficiency.

Summary Table:

| Disadvantage | Core Issue | Impact on Production |

|---|---|---|

| Inflexible Gating | Single parting line restricts gate to part edge (edge gating). | Cosmetic blemishes, non-ideal plastic flow, potential defects. |

| Manual Runner Removal | Runner system and parts eject as a single, connected piece. | Requires secondary operation, increases labor cost and cycle time, hinders automation. |

Struggling with inefficient moulding or cosmetic defects on your parts?

While two-plate moulds are cost-effective for simple projects, their limitations can hinder high-volume production and part quality.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise can help you select the right tooling solutions to optimize your moulding process, reduce operational costs, and achieve superior part quality.

Let's improve your production efficiency together. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Cylindrical Press Mold for Lab Applications

- No Demolding Lab Infrared Press Mold for Laboratory Applications

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Copper Foam

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- What is a 3 part mold for injection molding? Automate Your Production & Reduce Labor

- What are the critical functions of insulating molds? Enhancing Solid-State Battery Testing and Integrity

- How do graphite molds influence Ni–35Mo–15Cr microstructure? Enhance Alloys via Carbide Dispersion Strengthening

- What are three-plate molds? Precision Injection Molding for Complex Parts

- Why are high-precision PTFE molds necessary for solid-state Li-S batteries? Ensure Structural Integrity & Performance

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- What is the price of a mold press machine? Understand the True Cost & Investment for Your Production