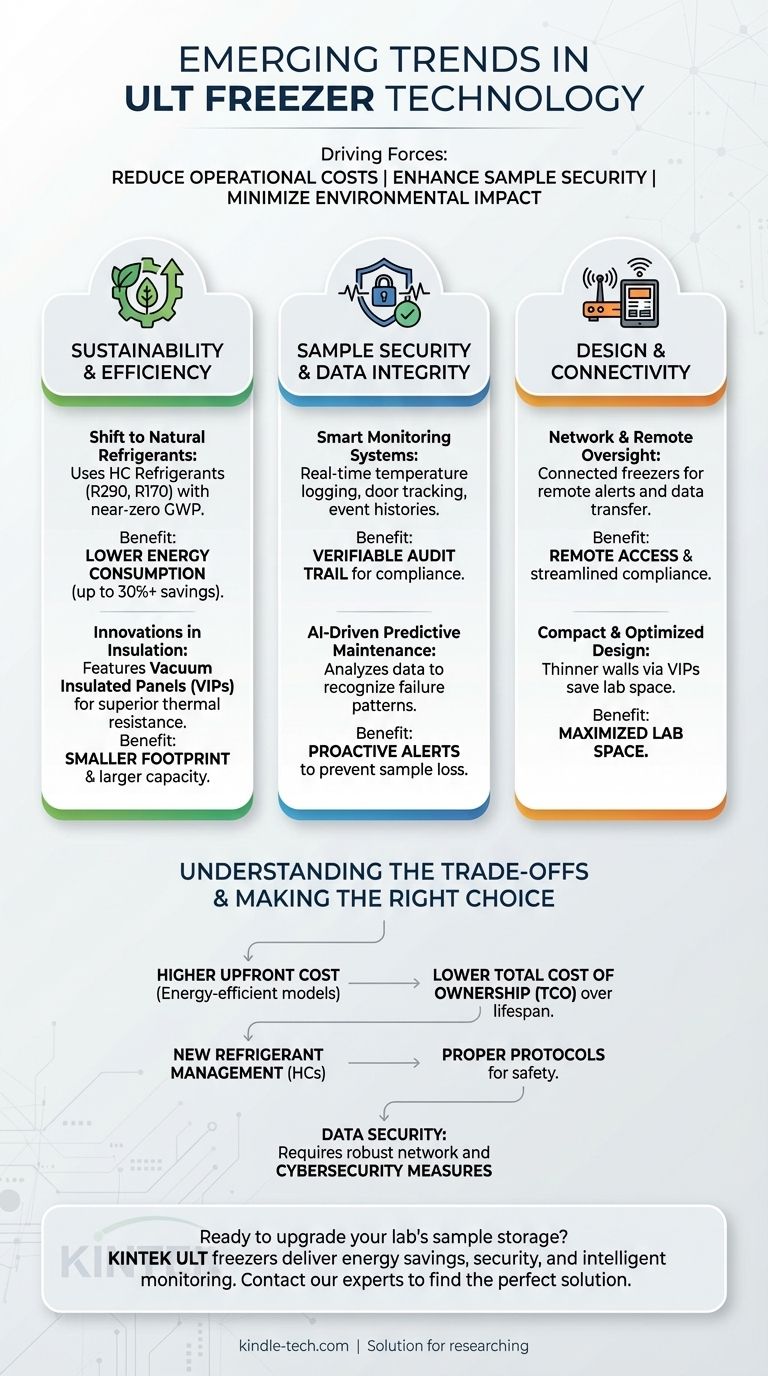

At its core, the evolution of Ultra-Low Temperature (ULT) freezer technology is driven by three primary goals: reducing operational costs, enhancing sample security, and minimizing environmental impact. Emerging trends center on adopting natural refrigerants for energy efficiency, integrating smart monitoring for data integrity and remote oversight, and optimizing physical design with advanced insulation for smaller footprints.

The central shift in ULT freezer design is from a purely mechanical device to an intelligent, sustainable, and data-connected asset. The focus is no longer just on maintaining temperature, but on doing so efficiently, reliably, and transparently to protect both valuable samples and operational budgets.

The Drive for Sustainability and Efficiency

The most significant operational challenge of traditional ULT freezers is their immense energy consumption. Modern innovations directly address this, driven by both cost-saving initiatives and increasing environmental regulations.

The Shift to Natural Refrigerants

Older ULT freezers rely on hydrofluorocarbons (HFCs), which are potent greenhouse gases. The industry is rapidly moving toward natural hydrocarbon (HC) refrigerants, such as R290 (propane) and R170 (ethane).

These refrigerants have a near-zero Global Warming Potential (GWP) and are thermodynamically more efficient. This translates directly into lower energy consumption—often reducing a freezer's power usage by 30% or more—and thus, lower electricity bills.

Innovations in Insulation and Design

To maintain ultra-low temperatures, freezers must combat heat ingress. Modern units replace traditional foam insulation with Vacuum Insulated Panels (VIPs).

These panels provide superior thermal resistance, allowing for thinner freezer walls. This results in either a larger internal storage capacity for the same external footprint or a more compact freezer, saving valuable laboratory floor space. Better insulation also means the compressor runs less frequently, further cutting energy use.

Enhancing Sample Security and Data Integrity

The value of the samples stored within a ULT freezer often far exceeds the cost of the unit itself. Consequently, new technologies are focused on proactive monitoring and preventing catastrophic failure.

The Rise of Smart Monitoring

Onboard smart monitoring systems are becoming standard. These systems go far beyond a simple high/low temperature alarm.

They provide real-time temperature logging, door opening tracking, and detailed event histories accessible directly from a touchscreen interface or a USB download. This creates an immediate, verifiable audit trail for compliance and quality control.

AI-Driven Predictive Maintenance

The next frontier is the integration of Artificial Intelligence (AI). Future freezers will use AI algorithms to analyze operational data, such as compressor cycle times and ambient temperature.

By recognizing patterns that precede a component failure, the system can issue a predictive maintenance alert. This allows service to be scheduled before a critical failure occurs, transforming maintenance from a reactive to a proactive process and virtually eliminating the risk of unexpected sample loss.

Understanding the Trade-offs

While these trends offer significant advantages, it is crucial to understand the associated considerations before making an investment.

Higher Upfront Cost vs. Total Cost of Ownership

Energy-efficient models with smart features typically have a higher initial purchase price. However, this cost is often recouped over the freezer's lifespan through substantial energy savings.

It is essential to calculate the Total Cost of Ownership (TCO), which includes not only the purchase price but also long-term energy and potential maintenance costs.

Management of New Refrigerants

While highly efficient, hydrocarbon refrigerants are flammable. Modern freezers are engineered with multiple safety features to completely mitigate this risk in normal operation. Labs must simply ensure they follow proper installation and service protocols specified by the manufacturer.

Reliance on Network and Data Security

Connected, "smart" freezers depend on your facility's network for remote alerts and data transfer. You must consider the reliability of your network and implement appropriate cybersecurity measures to protect the freezer's data and prevent unauthorized access.

Making the Right Choice for Your Goal

Selecting a ULT freezer is no longer just about temperature and capacity. It's a strategic decision that impacts your lab's budget, workflow, and risk management.

- If your primary focus is reducing operational costs: Prioritize models that use natural hydrocarbon refrigerants and feature advanced vacuum insulated panels for the lowest possible energy consumption.

- If your primary focus is maximum sample security: Choose a freezer with robust onboard monitoring, remote alert capabilities, and look toward emerging models with AI-driven predictive maintenance.

- If your primary focus is optimizing lab space and data management: Select a compact, VIP-insulated model with integrated data logging and network connectivity to streamline compliance and save floor space.

Ultimately, investing in modern ULT technology is an investment in the long-term sustainability and security of your research.

Summary Table:

| Trend | Key Feature | Primary Benefit |

|---|---|---|

| Sustainability & Efficiency | Natural Refrigerants (HCs) & Vacuum Insulated Panels (VIPs) | Lower energy costs (up to 30%+ savings) & smaller lab footprint |

| Sample Security & Data Integrity | Smart Monitoring & AI Predictive Maintenance | Proactive alerts, audit trails, and prevention of sample loss |

| Design & Connectivity | Network Connectivity & Compact Design | Remote oversight, compliance streamlining, and space optimization |

Ready to upgrade your lab's sample storage?

The latest Ultra-Low Temperature (ULT) freezers from KINTEK are engineered to deliver significant energy savings, unparalleled sample security, and intelligent monitoring—protecting your valuable research while reducing your total cost of ownership.

KINTEK specializes in advanced lab equipment, including energy-efficient ULT freezers tailored to meet the rigorous demands of modern laboratories.

Contact our experts today to find the perfect ULT solution for your specific needs and goals!

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C