The final product of a ball mill is a direct result of several controllable factors. The most significant of these are the rotational speed of the mill, the characteristics of the grinding media (such as size, material, and quantity), the properties of the material being ground, and the duration of the milling process. Understanding how to manipulate these variables is the key to achieving a consistent and predictable output.

Achieving your desired particle size isn't about finding one "perfect" setting. It's about understanding the dynamic relationship between mill speed, grinding media, and material properties to balance grinding efficiency with final product quality.

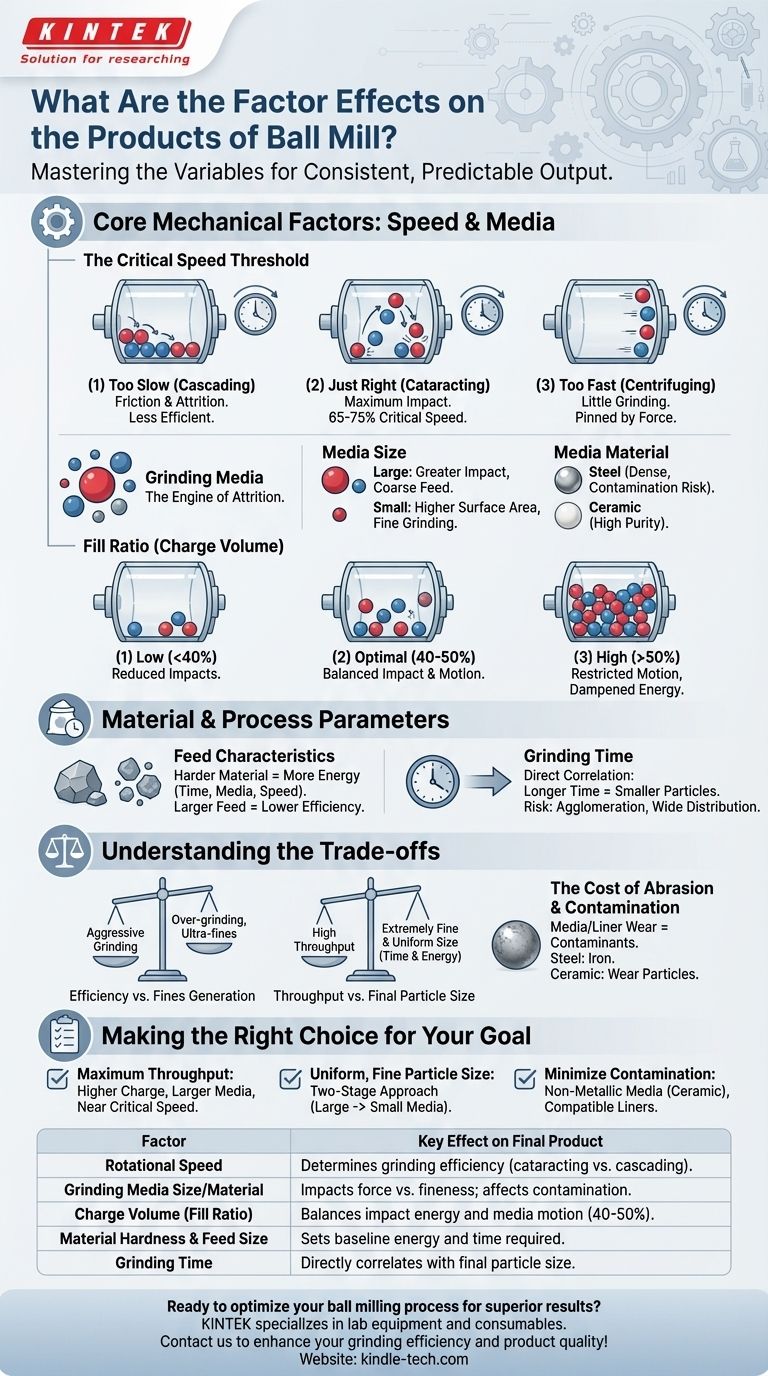

Core Mechanical Factors: Speed and Media

The physical setup of the mill and its media are the primary drivers of the grinding action. Getting these right is the first step toward process control.

The Critical Speed Threshold

A ball mill's rotational speed dictates the motion of the grinding media. This motion is directly responsible for breaking down the material.

- Too slow (Cascading): The balls tumble over one another, creating grinding action primarily through friction (attrition). This is less efficient for breaking large particles but can be useful for fine grinding.

- Too fast (Centrifuging): The balls are pinned to the outer wall of the mill by centrifugal force. They never fall, and little to no grinding occurs.

- Just right (Cataracting): At a "critical speed" (typically 65-75% of centrifuging speed), the balls are carried up the wall and then fall onto the material below. This creates the maximum impact force and is the most efficient speed for general-purpose grinding.

Grinding Media: The Engine of Attrition

The balls themselves are the tools doing the work. Their size, density, and material type have a profound effect on the final product.

- Media Size: Larger, heavier balls provide greater impact force, ideal for breaking down coarse, hard feed material. Smaller balls have a much higher surface area, making them more effective for fine grinding and creating a uniform final product.

- Media Material: Balls are commonly made of steel, stainless steel, ceramic, or even rubber. Steel is dense and effective but can introduce metallic contamination. Ceramic media is often used when product purity is critical.

Fill Ratio: Balancing Impact and Space

The "charge volume" refers to the percentage of the mill's internal volume filled with grinding media.

The optimal charge is typically between 40% and 50%. A lower fill level reduces the number of impacts and slows grinding. A fill level that is too high restricts the motion of the balls, dampening their fall and reducing impact energy.

Material and Process Parameters

Beyond the machine's mechanics, the material you put in and how long you process it are crucial variables that you can directly control.

Feed Characteristics

The starting condition of your material establishes the baseline for the entire process. A harder, less brittle material will require more energy—either through longer grinding times, heavier media, or higher speeds—to achieve the same size reduction as a softer material.

The initial particle size also matters. Feeding a mill with material that is too large for the chosen media will be highly inefficient.

Grinding Time

This is the most straightforward variable to adjust. All other factors being equal, longer grinding times result in smaller final particle sizes.

However, there is a point of diminishing returns. Excessive grinding can lead to particle agglomeration or create an undesirably wide distribution of particle sizes.

Understanding the Trade-offs

Optimizing a ball milling process is always a balancing act. Improving one metric often comes at the expense of another.

Efficiency vs. Fines Generation

Aggressive grinding—using high speeds and large, heavy media—is efficient at reducing particle size quickly. However, this high-energy process can "over-grind" a portion of the material, creating a large quantity of ultra-fine particles that may be undesirable.

Throughput vs. Final Particle Size

Achieving an extremely fine and uniform particle size requires significant time and energy. This directly reduces the overall throughput of your operation. You must decide whether speed of processing or precision of the final product is more important.

The Cost of Abrasion and Contamination

All grinding media and mill liners wear down over time. This process, known as abrasion, can introduce contaminants into your product.

Hard steel media wears slowly but is a common source of iron contamination. Softer ceramic media may eliminate metallic contamination but can wear more quickly, adding its own material to the product and requiring more frequent replacement.

Making the Right Choice for Your Goal

Your optimal settings depend entirely on what you prioritize. Use these principles as a starting point for developing your specific process.

- If your primary focus is maximum throughput: Use a higher ball charge (around 50%), larger media, and run near the critical speed to break down material quickly.

- If your primary focus is achieving a uniform, fine particle size: Consider a two-stage approach: an initial grind with larger media followed by a second, longer grind with smaller media at a slightly lower speed.

- If your primary focus is minimizing product contamination: Select ceramic or other non-metallic grinding media and ensure your mill liner is made of a compatible, abrasion-resistant material like rubber or a specific ceramic.

By methodically adjusting these variables, you can transform your ball mill from a simple grinder into a precision engineering tool.

Summary Table:

| Factor | Key Effect on Final Product |

|---|---|

| Rotational Speed | Determines grinding efficiency (cataracting vs. cascading). |

| Grinding Media Size/Material | Impacts force (large balls) vs. fineness (small balls); affects contamination. |

| Charge Volume (Fill Ratio) | Balances impact energy and media motion (optimal 40-50%). |

| Material Hardness & Feed Size | Sets baseline energy and time required for size reduction. |

| Grinding Time | Directly correlates with final particle size (with diminishing returns). |

Ready to optimize your ball milling process for superior results? KINTEK specializes in lab equipment and consumables, providing the right solutions for your laboratory's grinding needs. Whether you're focused on achieving a specific particle size, maximizing throughput, or ensuring product purity, our expertise can help. Contact us today to discuss how we can enhance your grinding efficiency and product quality!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding