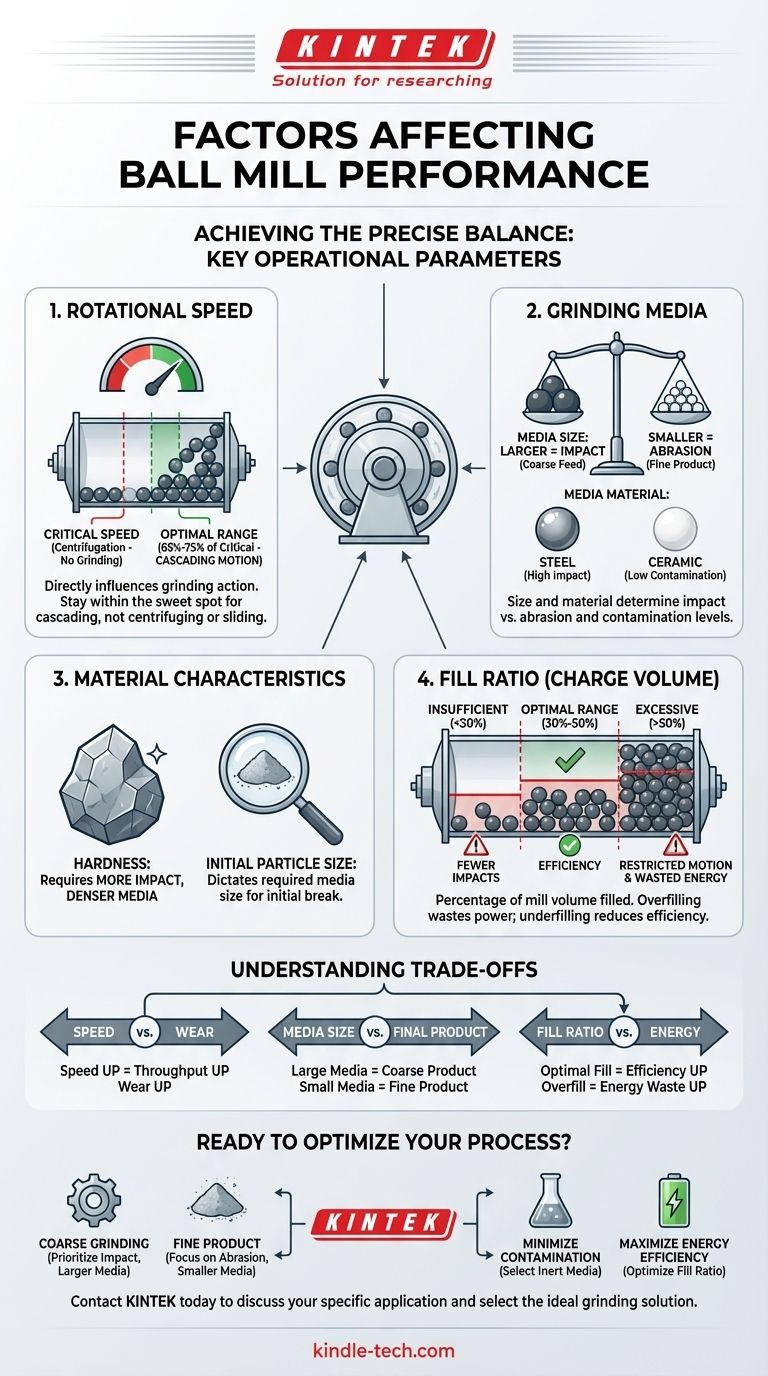

The performance of a ball mill is a direct result of a few key operational parameters. The primary factors you must control are the speed of the mill's rotation, the size and material of the grinding media (the balls), the characteristics of the material being ground, and the volume of grinding media loaded into the mill.

Optimizing a ball mill isn't about maximizing any single factor, but about achieving a precise balance between them. The goal is to create a continuous cascade of the grinding media that maximizes both impact and abrasion for the most efficient particle size reduction.

The Core Performance Levers

To truly control your milling process, you must understand how each primary factor influences the grinding action inside the mill. These are not independent settings; changing one will affect the optimal state of the others.

Rotational Speed and the "Critical Speed" Threshold

The most crucial factor is the rotational speed. This is measured relative to the critical speed, which is the theoretical speed where the grinding media begins to centrifuge—sticking to the inner wall of the mill instead of tumbling.

Operating at or above critical speed results in almost no grinding.

Conversely, operating at too low a speed causes the media to simply slide or roll at the bottom of the mill, providing minimal impact and inefficient grinding. The optimal speed is typically between 65% and 75% of the critical speed, creating a "cascading" motion that is essential for effective grinding.

The Role of the Grinding Media

The balls doing the work—the grinding media—have two key characteristics: size and material.

- Media Size: Larger, heavier balls create greater impact forces, which are ideal for breaking down coarse feed materials. Smaller balls create more contact points and favor abrasion, which is better for producing a very fine final product.

- Media Material: The density and hardness of the media are critical. Steel balls are common for high-impact applications. Ceramic or stainless steel balls are used when product contamination is a concern.

Material Characteristics

The properties of the material you are feeding into the mill directly influence the required setup.

Harder materials require more impact energy to break, often necessitating denser, larger grinding media and potentially higher operating speeds. The initial particle size of the feed also dictates the optimal size of the grinding media required for the initial break.

The Mill's Filling Ratio (Charge Volume)

This refers to the percentage of the mill's internal volume that is filled with the grinding media.

An insufficient charge volume reduces the number of grinding events (ball-on-ball and ball-on-material impacts), lowering efficiency.

An excessive charge volume restricts the motion of the media, preventing the necessary cascading action. This not only hinders grinding performance but also dramatically increases power consumption for no productive gain. A typical charge volume is between 30% and 50%.

Understanding the Trade-offs

Optimizing a ball mill is an exercise in balancing competing factors. Improving one metric can often come at the expense of another.

Speed vs. Wear

Increasing the rotational speed (while staying below the critical threshold) can increase throughput. However, this comes at the cost of significantly accelerated wear on both the grinding media and the mill's internal liner.

Media Size vs. Final Product

Using large media is highly effective for the initial stages of breaking down coarse material. However, those same large balls are very inefficient at grinding particles down to a very fine powder, as the spaces between the balls are too large.

Fill Ratio vs. Energy Consumption

Increasing the fill ratio can boost grinding efficiency up to a certain point. Beyond that optimal point, however, the power required to turn the mill increases dramatically with little to no improvement in grinding performance. Overfilling is a primary cause of wasted energy.

How to Apply This to Your Process

Your specific goal should dictate your approach to tuning these parameters.

- If your primary focus is coarse grinding or breaking down large particles: Prioritize impact forces by using larger, denser grinding media and operating in the higher range of the optimal speed window (e.g., 70-75% of critical speed).

- If your primary focus is achieving a very fine final product: Focus on abrasion by using smaller grinding media to increase surface area and contact points. A slightly lower speed may be more effective.

- If your primary focus is minimizing product contamination: Your first choice must be the media material, selecting inert options like ceramic or stainless steel.

- If your primary focus is maximizing energy efficiency: Carefully optimize the mill's filling ratio (charge volume), as running with either too little or too much media is a primary cause of wasted power.

Mastering these factors transforms ball milling from a brute-force process into a precise and predictable engineering operation.

Summary Table:

| Factor | Key Influence on Performance | Optimal Range/Consideration |

|---|---|---|

| Rotational Speed | Determines grinding media motion (cascade vs. centrifugation) | 65% - 75% of critical speed |

| Grinding Media Size | Balances impact force (coarse grinding) vs. abrasion (fine grinding) | Larger for coarse feed, smaller for fine product |

| Grinding Media Material | Affects contamination and impact energy (e.g., steel vs. ceramic) | Choose based on material hardness and purity needs |

| Material Characteristics | Dictates required energy and media type for effective breakage | Harder materials need denser media/higher impact |

| Fill Ratio (Charge Volume) | Impacts grinding efficiency and power consumption | Typically 30% - 50% of mill volume |

Ready to Optimize Your Milling Process?

Achieving the perfect balance of speed, media, and fill ratio is key to maximizing your ball mill's efficiency and product quality. The experts at KINTEK specialize in lab equipment and consumables, providing the precise grinding media and technical support you need to transform your milling into a predictable, high-performance operation.

Contact KINTEK today to discuss your specific application and let our specialists help you select the ideal grinding solution for your laboratory's needs.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why is a planetary ball mill preferred over manual grinding for LiZr2(PO4)3? Achieve High-Conductivity Powder Synthesis

- What is the primary function of a planetary ball mill in graphite regeneration? Enhance Recycled Battery Capacity

- What role does a high-energy ball mill play in the synthesis of halide solid electrolytes like Li3YCl6 and Li3InCl6?

- What factors influence the size of the product in the ball mill? Master Grinding Media, Speed, and Feed for Precision

- What is the function of a planetary ball mill in LSLBO synthesis? Master High-Performance Ceramic Electrolyte Production

- What role does a high-energy ball mill play in Pt/Pd alloy metallurgy? Unlock Superior Catalytic & Mechanical Power

- What are the sizes of a ball mill? From Benchtop to Industrial Scale Solutions

- What is the function of a ball mill and a standard sieve? Optimize Converter Matte for Electrolytic Reduction