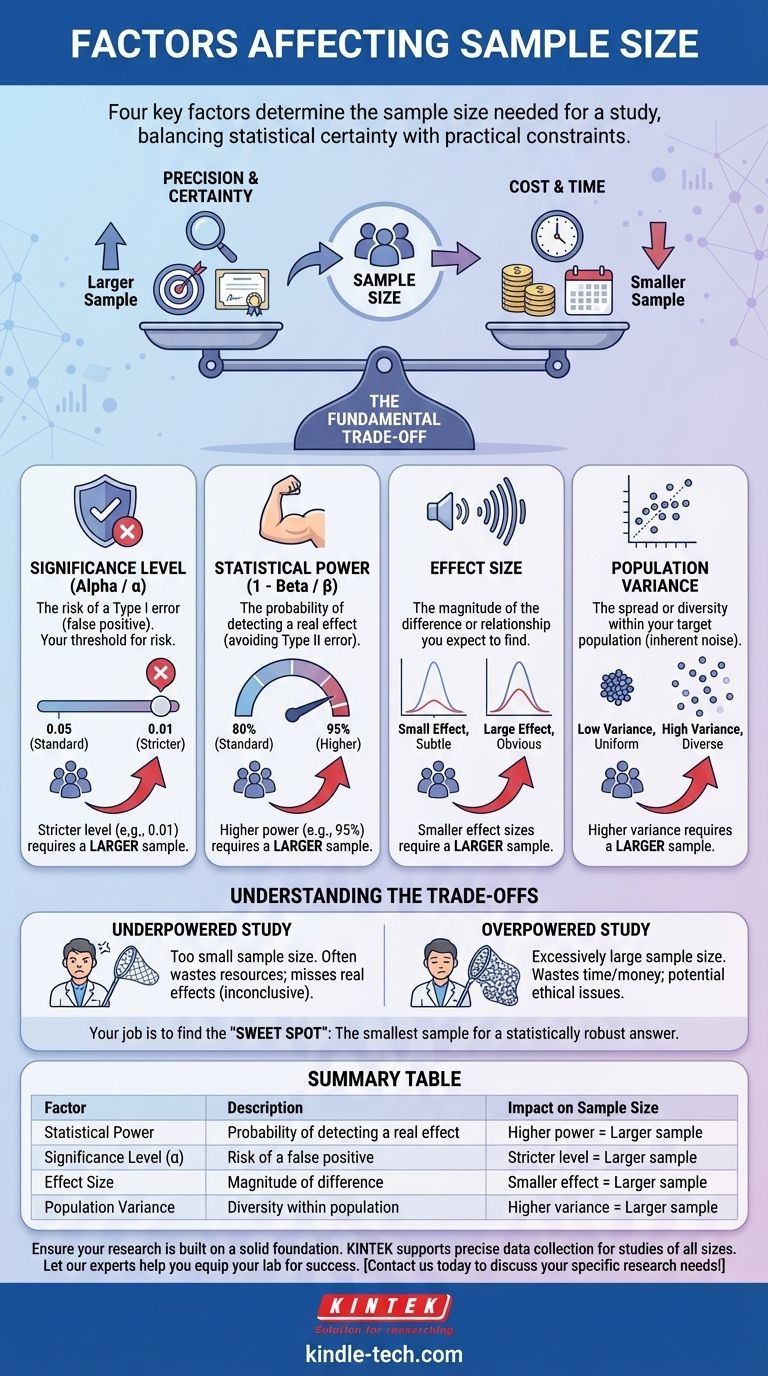

Ultimately, four key factors determine the sample size you need for a study: the desired statistical power, the significance level you set, the size of the effect you wish to detect, and the variability within the population you are studying. These elements work together to balance the need for statistical certainty against practical constraints like time and budget.

The core challenge of choosing a sample size is managing a fundamental trade-off. You are balancing the desire for precision and certainty (which requires a larger sample) against the practical limitations of cost and time (which push for a smaller sample).

The Core Statistical Concepts Driving Sample Size

To make an informed decision, you must first understand the statistical principles at play. These are not just abstract rules; they are the levers you can pull to control the reliability of your results.

Significance Level (Alpha / α)

The significance level, often set at 0.05 (or 5%), is your threshold for risk. It represents the probability of making a "Type I error"—concluding there is an effect when, in reality, there isn't one.

A smaller alpha (e.g., 0.01) means you are being more cautious and want to be more certain before claiming a result is significant. This stricter standard requires a larger sample size to meet the higher burden of proof.

Statistical Power (1 - Beta / β)

Power is the probability that your study will detect an effect if there truly is one. It’s the opposite of a "Type II error" (failing to find a real effect).

A common standard for power is 80%. Increasing your desired power to 90% or 95% reduces your risk of missing a genuine discovery, but this increased certainty requires a larger sample size.

Effect Size

Effect size is the magnitude of the difference or relationship you expect to find. It’s the signal you are trying to detect.

Detecting a small, subtle effect is like trying to hear a whisper in a crowded room; you need to listen very carefully (i.e., use a large sample). Detecting a large, obvious effect is like hearing a shout; it's easy to notice even with a small sample. Therefore, smaller effect sizes require larger samples.

Population Variance

Variance (or standard deviation) measures the spread or diversity within your target population. It represents the inherent "noise" in your data.

If a population has very low variability (e.g., most people are very similar), a small sample is sufficient to represent them. If the population is highly diverse with a lot of variability, you need a larger sample to capture that diversity and distinguish the signal from the noise.

Understanding the Trade-offs

Choosing a sample size is never a purely mathematical exercise. It involves strategic decisions about resources and acceptable levels of risk.

The Risk of an Underpowered Study

A study with a sample size that is too small is considered "underpowered." This is the most common pitfall.

An underpowered study is often a complete waste of resources. Even if a real effect exists, the study lacks the statistical power to detect it, leading to an inconclusive or misleading "negative" result.

The Inefficiency of an Overpowered Study

Conversely, a sample size that is excessively large is "overpowered." While it provides high precision, it wastes time and money.

In clinical or user research, it can also be unethical, as it exposes more participants than necessary to potential risks or interventions for a result that could have been confirmed with fewer data points.

Precision vs. Practicality

The core conflict is clear. Statisticians will always advocate for larger samples to increase certainty. Project managers and budget holders will push for smaller samples to save resources.

Your job is to find the "sweet spot": the smallest sample size that provides a statistically robust and credible answer to your research question.

How to Determine Your Sample Size

To move forward, you must define your priorities. The right sample size depends entirely on the goal of your study and the resources you have available.

- If your primary focus is detecting a very small, subtle effect: You must commit to a large sample size, as this is the only way to have sufficient power.

- If your primary focus is an exploratory study with a limited budget: You may need to accept lower power or only aim to detect larger, more obvious effects.

- If your primary focus is minimizing the risk of false negatives (missing a real effect): You must increase the statistical power (e.g., to 90%), which will require a larger sample.

- If your primary focus is minimizing the risk of false positives (claiming an effect that isn't real): You must use a stricter significance level (e.g., 0.01), which also increases the required sample size.

A thoughtfully chosen sample size is the foundation of credible and reliable research.

Summary Table:

| Factor | Description | Impact on Sample Size |

|---|---|---|

| Statistical Power | Probability of detecting a real effect | Higher power = Larger sample |

| Significance Level (α) | Risk of a false positive (Type I error) | Stricter level (e.g., 0.01) = Larger sample |

| Effect Size | Magnitude of the difference or relationship | Smaller effect = Larger sample |

| Population Variance | Diversity or spread within the population | Higher variance = Larger sample |

Ensure your research is built on a solid foundation. Choosing the right sample size is critical for obtaining credible, reliable results. KINTEK specializes in providing the lab equipment and consumables that support precise data collection for studies of all sizes. Let our experts help you equip your lab for success. Contact us today to discuss your specific research needs!

Visual Guide

Related Products

- Lab Vibration Mill

- Three-dimensional electromagnetic sieving instrument

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What are the advantages and disadvantages of heat treatment? Master Material Properties for Your Application

- What is the maximum pressure for a filter press? Choosing the Right PSI for Your Process

- What are the uses of furnace in laboratory? A Guide to Material Transformation & Analysis

- How does a 3 stage furnace work? Achieve Superior Comfort and Efficiency

- What are the products of pyrolysis of oil sludge? Turn Hazardous Waste into Valuable Resources

- How does the refrigeration system of an Ultra Freezer work? The Two-Stage Cascade Cooling Explained

- What is the maximum service temperature for brazed joints? Unlock the Key to Joint Reliability and Performance

- Is it fitting the mould or mold? A Guide to Correct Spelling by Region