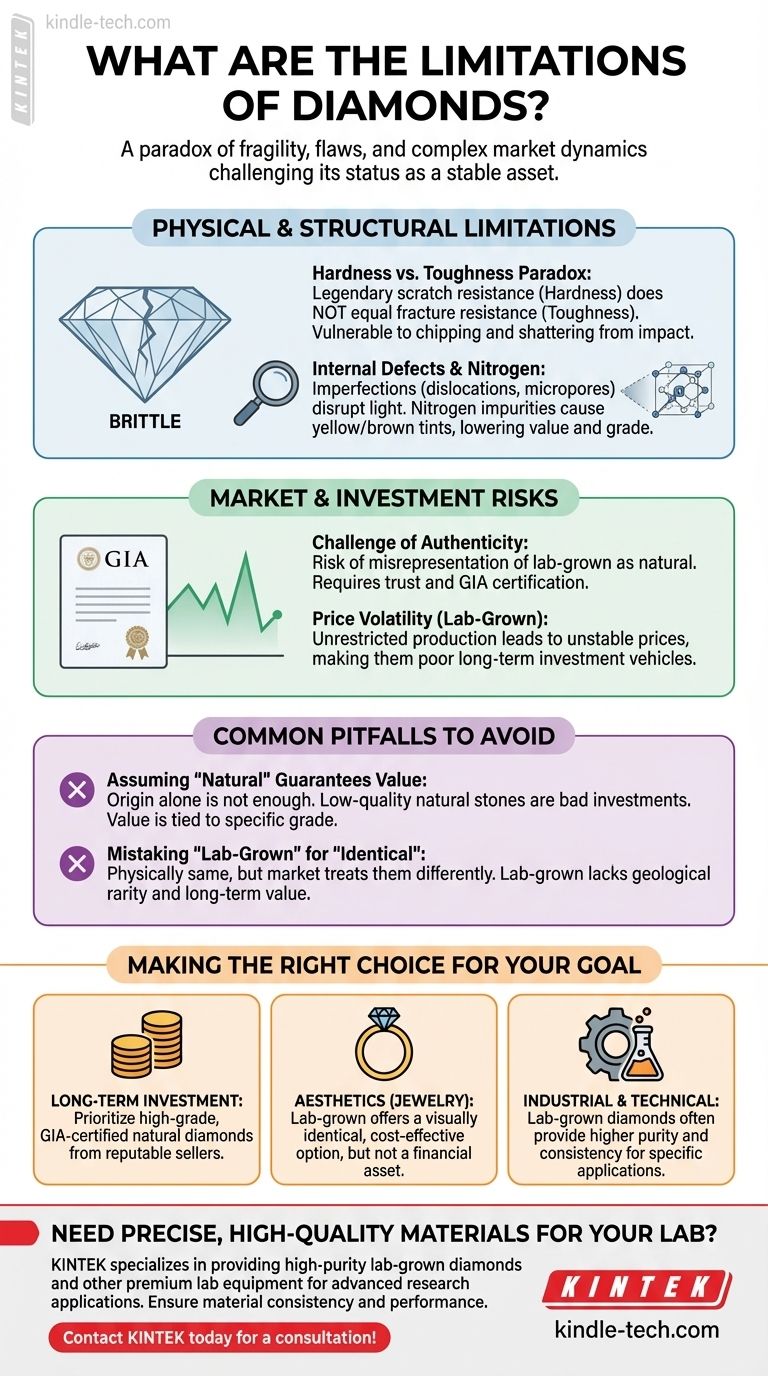

Contrary to their reputation for indestructibility, diamonds have significant limitations. Their primary weaknesses are a surprising degree of brittleness despite their hardness, susceptibility to internal structural defects that affect their quality, and considerable market risks related to authenticity and price volatility, especially when comparing natural and lab-grown stones.

The core limitation to understand is that a diamond's "perfection" is a myth. Its value and utility are constrained by a paradox of physical fragility, inherent internal flaws, and complex market dynamics that challenge its status as a stable asset.

Physical and Structural Limitations

While famous for being the hardest natural material, a diamond's physical properties are not without drawbacks. These internal and structural weaknesses directly impact its quality, durability, and grade.

The Hardness vs. Toughness Paradox

A diamond's hardness—its ability to resist scratching—is legendary. However, this is distinct from its toughness, which is its ability to resist fracturing from impact.

Diamonds are relatively brittle. A sharp, well-placed blow can cause a diamond to chip, fracture, or even shatter along its cleavage planes.

The Impact of Internal Defects

No diamond is perfectly formed. The "grade" of a diamond is largely determined by the presence and severity of its internal flaws.

Key defects include dislocations (irregularities in the crystal lattice) and features like micropores formed by vacancies in the atomic structure. These imperfections can disrupt the passage of light, reducing the stone's brilliance and clarity.

How Nitrogen Content Affects Quality

The most common impurity found in diamonds is nitrogen. The concentration and arrangement of nitrogen atoms within the crystal lattice are primary factors that determine a diamond's color.

High nitrogen content often imparts a yellow or brownish tint, lowering the stone's grade and value. The presence of these atoms is a fundamental limitation on achieving a perfectly colorless natural diamond.

Market and Investment Risks

The value of a diamond is not guaranteed. It is subject to market forces, questions of authenticity, and the growing influence of synthetic alternatives.

The Challenge of Authenticity

A significant risk in the diamond market is the misrepresentation of lab-grown diamonds as natural ones. This requires buyers to place immense trust in sellers and the certification process.

Without a reputable certificate from an institution like the Gemological Institute of America (GIA), it is difficult for a non-expert to verify a natural diamond's origin and authenticity.

Price Volatility of Lab-Grown Diamonds

The value of lab-grown diamonds is particularly unstable. Because production is unrestricted and competition among manufacturers is increasing, their prices change relatively quickly.

This makes lab-grown diamonds a poor choice for anyone considering them a long-term store of value or investment vehicle.

Common Pitfalls to Avoid

Navigating the diamond market requires understanding the core trade-offs between natural and lab-grown stones, as buyers often fall into traps by misjudging their goals.

Assuming "Natural" Guarantees Value

The primary pitfall with natural diamonds is assuming their origin alone guarantees their investment potential. A low-quality natural stone with significant defects and poor color is not a sound investment.

Value is tied to the specific grade of the diamond, as verified by a trusted certificate.

Mistaking "Lab-Grown" for "Identical"

While physically and chemically the same, the market treats lab-grown and natural diamonds differently. A buyer focused on price may overlook that a lab-grown diamond lacks the geological rarity that underpins the long-term value of its natural counterpart.

Their value propositions are entirely different: one is a manufactured good, the other a finite natural resource.

Making the Right Choice for Your Goal

Your decision should be guided by your primary objective, as the limitations of diamonds impact each goal differently.

- If your primary focus is long-term investment: Prioritize a high-grade, GIA-certified natural diamond from a highly reputable seller to mitigate risks of authenticity and ensure quality.

- If your primary focus is aesthetics for jewelry: A lab-grown diamond offers a visually identical and more cost-effective option, but do not consider it a financial asset.

- If your primary focus is industrial or technical application: The key is the specific grade and physical properties; lab-grown diamonds often provide higher purity and consistency for these uses.

Ultimately, understanding these limitations empowers you to see diamonds not as a perfect material, but as a complex one with specific strengths and weaknesses.

Summary Table:

| Limitation Category | Key Takeaway |

|---|---|

| Physical & Structural | Hard but brittle; internal flaws affect clarity and color. |

| Market & Investment | Authenticity risks and price volatility, especially for lab-grown stones. |

| Common Pitfalls | Assuming 'natural' guarantees value or that lab-grown is an 'identical' investment. |

Need Precise, High-Quality Materials for Your Lab?

While diamonds have their limitations for jewelry and investment, their properties are critical for advanced industrial and research applications. KINTEK specializes in providing high-purity lab-grown diamonds and other premium lab equipment and consumables. We ensure the material consistency and performance your laboratory demands.

Let our experts help you select the perfect materials for your specific application.

Contact KINTEK today for a consultation!

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- Can pyrolysis oil be refined? Unlocking High-Value Fuels from Bio-Crude

- How much energy does a filter press use? The Real Power Draw is the Feed Pump

- What are the industrial applications of centrifuge? Powering Separation in Food, Pharma & Waste Management

- What are the stages of melting metal? Mastering the 3-Step Process from Solid to Liquid

- What temperature should a furnace run at? From Home Comfort to Industrial Processes

- What are the different types of frames in compression? A Guide to I, P, and B-Frames

- What are the safety considerations for titanium? From Biocompatible Metal to Fire Hazard

- Can graphite withstand heat? Unlocking its extreme 3,600°C potential in inert environments