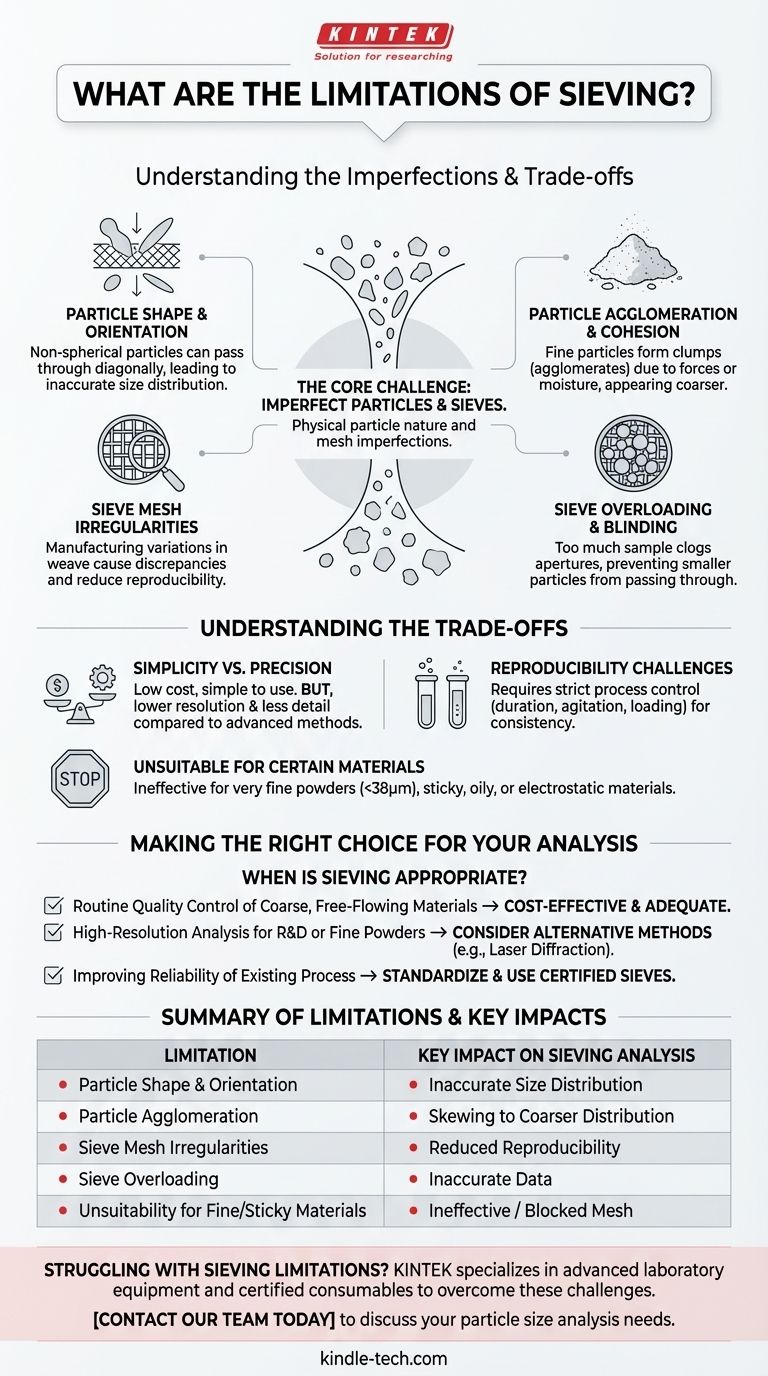

The primary limitations of sieving stem from the physical nature of the particles and the inherent imperfections of the sieve mesh itself. Factors like particle shape, the tendency for fine particles to clump together, and variations in the sieve weave all introduce potential inaccuracies and challenges with reproducibility.

Sieving is a mechanically straightforward method for particle size analysis, but its effectiveness is fundamentally constrained by the real-world deviation from the ideal scenario of perfectly spherical particles falling through a perfectly uniform grid.

The Core Challenge: Imperfect Particles and Sieves

Sieving operates on a simple principle: particles smaller than the mesh openings pass through, while larger ones are retained. However, this simplicity masks several underlying complexities that define the method's limitations.

Particle Shape and Orientation

The most significant limitation is that sieving measures only one dimension of a particle at a time. An elongated or flat particle can pass through a sieve aperture diagonally or on its edge, even if its longest dimension is much larger than the opening. This leads to an underestimation of the true size distribution for non-spherical materials.

Particle Agglomeration and Cohesion

Fine powders often stick together due to electrostatic forces or moisture, forming larger agglomerates. These clumps behave as single large particles, preventing the individual fine particles from passing through the correct sieve. This skews the results, making the material appear coarser than it actually is.

Sieve Mesh Irregularities

No sieve is perfect. Manufacturing tolerances mean that the apertures within a single sieve mesh are not perfectly uniform in size and shape. As noted in testing standards, these variations in the weave can cause discrepancies and directly impact the reproducibility of results between different sieves, even those with the same nominal rating.

Sieve Overloading and Blinding

Using too much sample material can easily overload the sieve. This can cause the mesh to become clogged, or "blinded," by particles wedged in the apertures. When this happens, it creates a barrier that prevents subsequent, smaller particles from having the opportunity to pass through, leading to inaccurate results.

Understanding the Trade-offs of Sieving

While these limitations are important, sieving remains a widely used technique because of its practical advantages. Understanding the trade-offs is key to using it effectively.

Simplicity vs. Precision

Sieving is valued for its low cost, simplicity, and ease of use. However, this comes at the cost of precision. It provides a less detailed and lower-resolution view of particle size distribution compared to more advanced methods like laser diffraction or dynamic image analysis.

Reproducibility Challenges

Achieving highly reproducible results requires strict control over the entire process. Beyond the physical state of the sieves themselves, factors like sieving duration, the intensity of agitation, and sample loading procedures must be rigorously standardized to minimize variability.

Unsuitability for Certain Materials

Sieving is generally not the appropriate method for very fine powders (typically below 38 microns), where agglomeration and static effects become dominant. It is also ineffective for materials that are sticky, oily, or have a strong electrostatic charge, as these properties prevent particles from moving freely on the mesh.

Making the Right Choice for Your Analysis

Your analytical goal should determine whether sieving is the appropriate method or if its limitations are too significant for your application.

- If your primary focus is routine quality control of coarse, free-flowing materials: Sieving is often a cost-effective and perfectly adequate method for ensuring product consistency.

- If your primary focus is high-resolution analysis for R&D or fine powders: You should consider alternative methods like laser diffraction or image analysis to overcome the precision and particle shape limitations of sieving.

- If your primary focus is improving the reliability of an existing sieving process: Standardize your sample size and sieving time, and use certified sieves to mitigate the impact of mesh variations.

Acknowledging these limitations is the first step toward generating reliable and meaningful particle size data.

Summary Table:

| Limitation | Key Impact on Sieving Analysis |

|---|---|

| Particle Shape & Orientation | Non-spherical particles can pass through apertures diagonally, leading to inaccurate size distribution. |

| Particle Agglomeration & Cohesion | Fine particles clump together, behaving as larger particles and skewing results towards a coarser distribution. |

| Sieve Mesh Irregularities | Variations in the weave of the mesh itself cause discrepancies and reduce reproducibility between sieves. |

| Sieve Overloading & Blinding | Too much sample clogs the mesh, preventing smaller particles from passing through and yielding inaccurate data. |

| Unsuitability for Fine/Sticky Materials | Ineffective for powders below ~38 microns or materials that are sticky, oily, or highly electrostatic. |

Struggling with the limitations of sieving for your particle analysis? KINTEK specializes in providing advanced laboratory equipment and consumables to overcome these challenges. Whether you need more precise analytical technologies like laser diffraction or high-quality, certified sieves to improve your current process reproducibility, our experts can help you select the ideal solution for your specific materials and accuracy requirements.

Contact our team today to discuss your particle size analysis needs and ensure reliable, meaningful data for your laboratory.

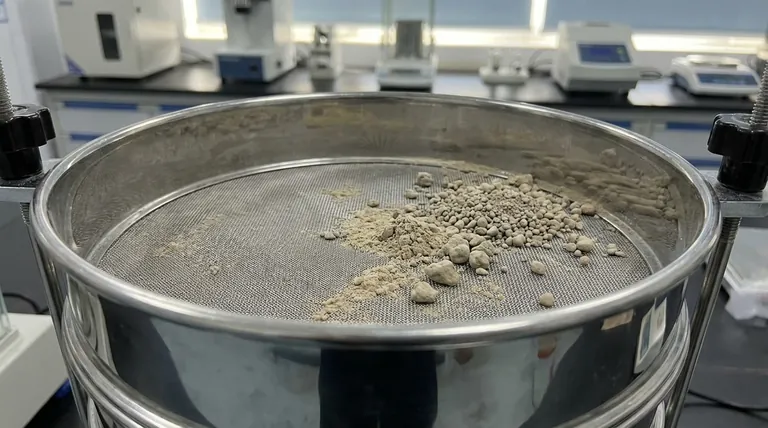

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability