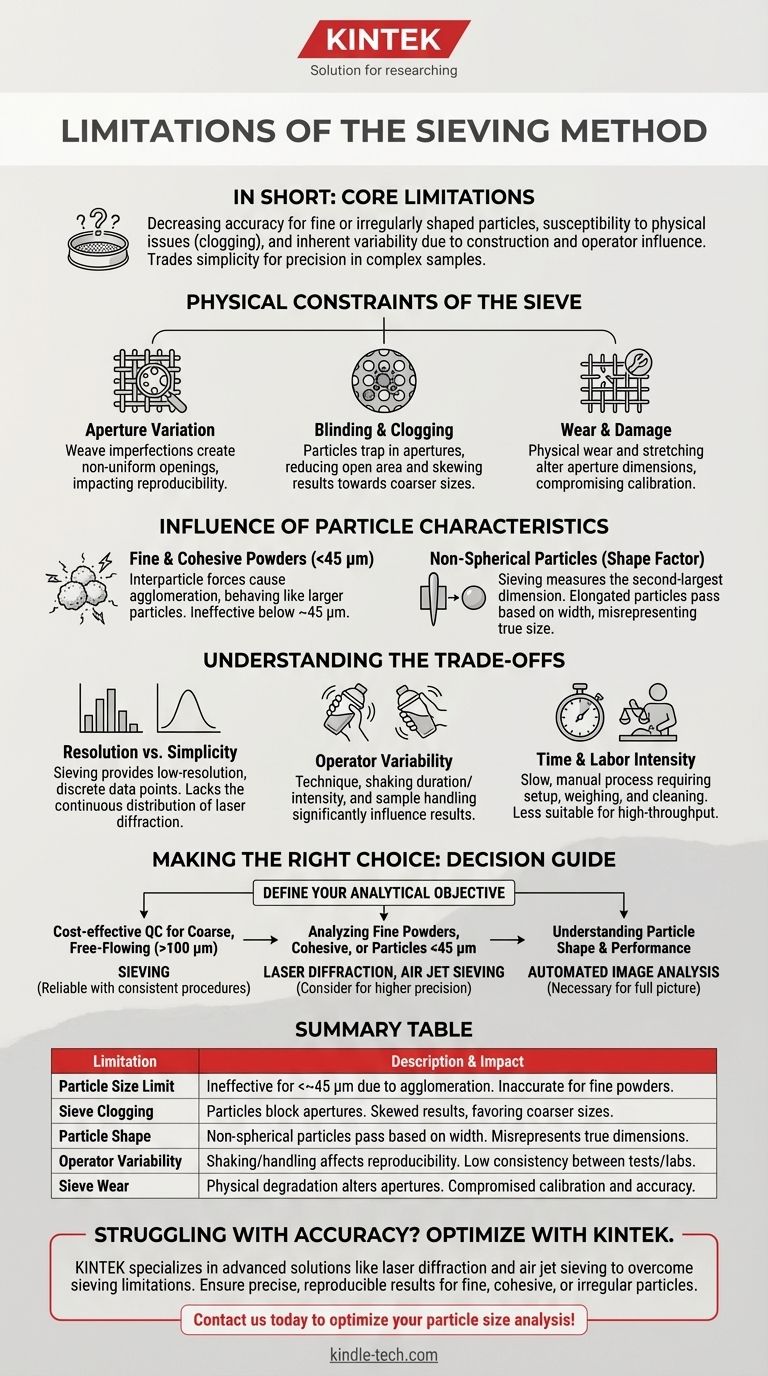

In short, the primary limitations of the sieving method are its decreasing accuracy for very fine or irregularly shaped particles, its susceptibility to physical issues like mesh clogging, and its inherent variability due to both the sieve construction and operator influence. While robust for coarse materials, it struggles to provide a complete or consistently reproducible picture for more complex samples.

Sieving is a foundational technique for particle size analysis, but its reliability is fundamentally tied to the simple mechanical separation of particles. Its limitations emerge when particle size, shape, or cohesiveness prevents this physical interaction from being accurate or repeatable, forcing a trade-off between simplicity and precision.

The Physical Constraints of the Sieve Itself

The tool itself is often the first source of error. The physical nature of a woven-wire sieve introduces inherent limitations that cannot be ignored in high-precision applications.

Aperture Variation and Weave Imperfections

Even in a high-quality, certified test sieve, the openings (apertures) are not perfectly uniform. The process of weaving wire creates a distribution of aperture sizes around a nominal value.

This variation means some particles that should be retained may pass through, and some that should pass may be retained, slightly skewing the results. This directly impacts the reproducibility of the analysis between different sieves of the same nominal size.

Sieve Blinding and Clogging

Blinding occurs when particles become trapped in the sieve apertures, effectively reducing the open area available for separation. This is especially common with particles that are very close to the size of the opening.

Materials that are fibrous or elongated are also prone to clogging the mesh. This prevents other particles from being properly sorted and leads to an inaccurate result that is biased toward coarser particle sizes.

Wear, Damage, and Deformation

Sieves are subject to physical wear. Over time, the abrasive action of particles and the mechanical stress of shaking can cause wires to stretch, sag, or even break.

This damage alters the aperture dimensions, compromising the sieve's calibration and the accuracy of any subsequent tests. Regular inspection and recalibration are critical to mitigate this.

The Influence of Particle Characteristics

The nature of the material being tested is just as important as the equipment. Sieving relies on the assumption that particles will flow freely and separate based on size alone, which is often not the case.

The Lower Limit: Fine and Cohesive Powders

Sieve analysis becomes progressively less effective for particles below approximately 45 micrometers (μm). At this scale, interparticle forces like van der Waals and electrostatic charges become stronger than gravitational forces.

These forces cause fine particles to clump together (agglomerate). The shaker's energy is often insufficient to break these agglomerates apart, meaning they behave like single, larger particles and are retained on a much coarser sieve, completely misrepresenting the true particle size distribution.

The Shape Factor: Non-Spherical Particles

Sieving fundamentally measures a particle's second-largest dimension. A long, needle-like particle can easily pass through a sieve opening end-on, even if its length is many times larger than the aperture size.

This means sieving provides a limited, one-dimensional view of particle size. It cannot distinguish between a sphere and a long fiber if they share a similar width, a critical detail that methods like image analysis can capture.

Understanding the Trade-offs

Choosing a method requires acknowledging its compromises. Sieving is valued for its simplicity and low cost, but this comes at the expense of resolution and analytical depth.

Resolution vs. Simplicity

Sieve analysis produces a discrete, histogram-style result. You get a data point for each sieve in the stack, but no information about the particle distribution between those sieve sizes.

In contrast, methods like laser diffraction produce a continuous, high-resolution distribution curve. The resolution of a sieve test is limited by the number and availability of sieve sizes you choose to use.

Operator-Dependent Variability

The final result can be significantly influenced by the technician. Factors like the sample loading technique, the precise duration and intensity of shaking (on uncalibrated shakers), and the thoroughness of collecting and weighing each fraction can introduce variability.

This makes it difficult to achieve high reproducibility between different operators or different labs without extremely rigid and well-documented standard operating procedures (SOPs).

Time and Labor Intensity

Compared to modern, automated techniques, traditional sieve analysis is slow. It requires manual setup, sample weighing before and after, running the test (which can take 15-30 minutes), and careful cleaning. This makes it less suitable for high-throughput environments.

Making the Right Choice for Your Goal

To select the correct method, you must first define your analytical objective.

- If your primary focus is cost-effective quality control for coarse, free-flowing materials (>100 μm): Sieving is likely an excellent and reliable choice, provided you use a consistent procedure and well-maintained equipment.

- If your primary focus is analyzing fine powders, cohesive materials, or particles below 45 μm: You should strongly consider alternative methods like laser diffraction, air jet sieving, or dynamic light scattering.

- If your primary focus is understanding particle shape and its impact on performance: Sieving is inadequate; a technique like automated or dynamic image analysis is necessary to get the full picture.

Ultimately, recognizing these limitations allows you to use sieving effectively where it excels and to choose a more appropriate tool when your application demands higher precision.

Summary Table:

| Limitation | Description | Impact |

|---|---|---|

| Particle Size Limit | Ineffective for particles below ~45 μm due to agglomeration. | Inaccurate results for fine powders. |

| Sieve Clogging/Blinding | Particles block apertures, reducing open area for separation. | Skewed results favoring coarser sizes. |

| Particle Shape Influence | Non-spherical particles (e.g., fibers) pass through based on width, not length. | Misrepresents true particle dimensions. |

| Operator Variability | Shaking intensity, duration, and sample handling affect reproducibility. | Low consistency between tests or labs. |

| Sieve Wear & Damage | Physical degradation alters aperture sizes over time. | Compromised calibration and accuracy. |

Struggling with particle analysis accuracy? KINTEK specializes in lab equipment and consumables, offering advanced solutions like laser diffraction and air jet sieving to overcome the limitations of traditional sieving. Whether you work with fine powders, cohesive materials, or irregular particles, our expertise ensures precise, reproducible results for your laboratory needs. Contact us today to optimize your particle size analysis!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability