At its core, a laboratory freeze dryer is a specialized machine used to remove water from sensitive materials without damaging their structure. Its primary applications are in the pharmaceutical industry for preserving medications like vaccines, in biotechnology and clinical research for stabilizing biological samples, and in advanced food science for creating high-quality, long-lasting products. The process, known as lyophilization, makes materials stable for long-term storage and easier to transport.

The central value of freeze drying is not simply dehydration, but preservation. By turning ice directly into vapor under a vacuum, it bypasses the destructive liquid water phase, keeping the delicate molecular and physical structure of a substance intact.

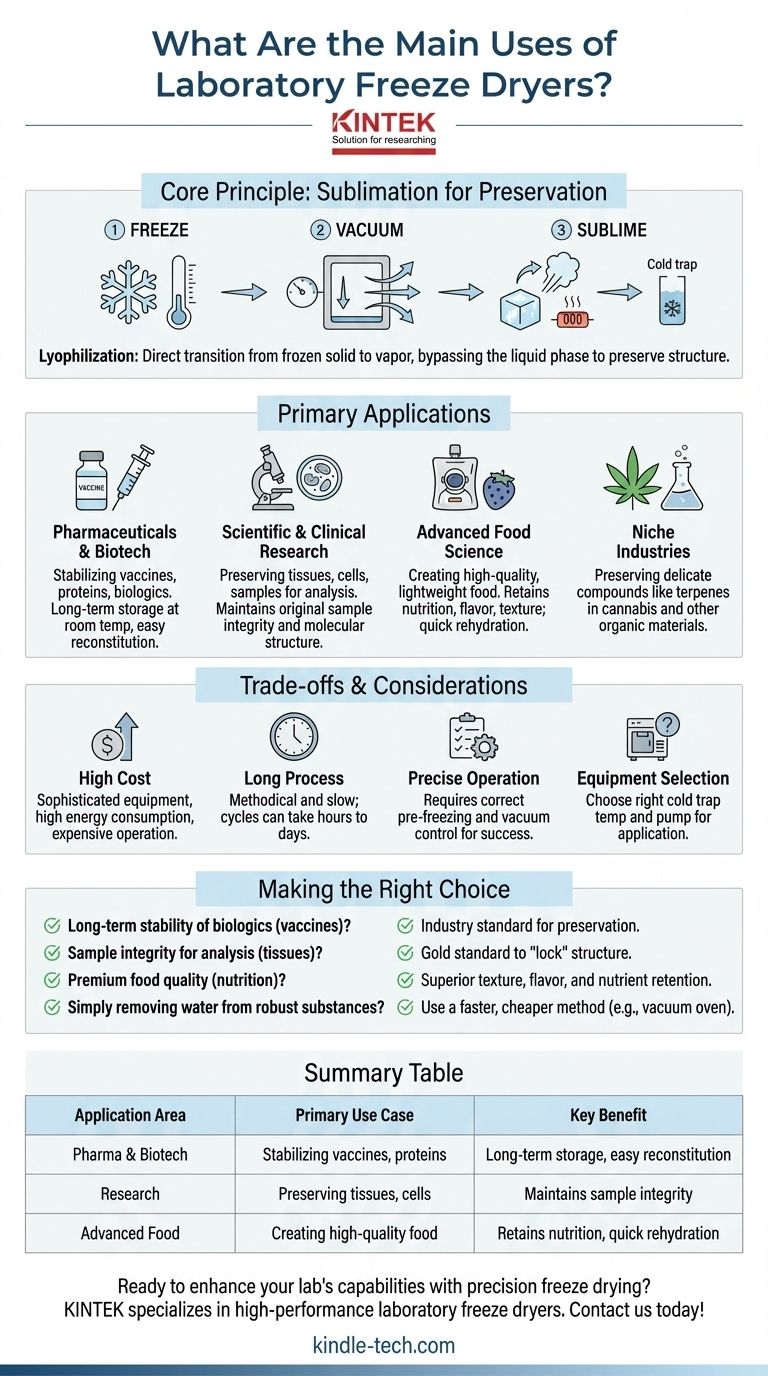

The Core Principle: Sublimation for Preservation

What is Freeze Drying (Lyophilization)?

Lyophilization is a three-step process. First, the material is completely frozen. This locks its structure in place.

Second, it is placed under a deep vacuum. This significantly lowers the pressure around the material.

Finally, a small amount of heat is carefully introduced. Under these low-pressure conditions, the frozen water in the material doesn't melt into a liquid; instead, it turns directly into a gas (water vapor) in a process called sublimation. This vapor is then collected on a freezing-cold coil, called a cold trap.

Why This Matters for Sensitive Materials

Traditional drying uses heat to evaporate liquid water. This process can be destructive, causing materials to shrink, proteins to denature, and cell walls to collapse.

Freeze drying avoids this damage entirely. By keeping the material frozen solid while the water is removed, its original size, shape, and—most importantly—its biological or chemical integrity are preserved.

Primary Applications in Detail

Pharmaceuticals and Biotechnology

This is arguably the most critical application. Freeze drying is used to increase the shelf life of injectable drugs, vaccines, proteins, and other biologics that are unstable in a liquid state.

The resulting dry powder can be stored for years, often at room temperature, and then quickly reconstituted with sterile water just before use. This dramatically simplifies storage and transportation logistics.

Scientific and Clinical Research

Biologists and chemists rely on freeze dryers to preserve tissues, cells, proteins, and nucleic acids for later analysis. The process effectively pauses all biological and chemical activity without altering the sample's structure.

This ensures that the results of a future analysis reflect the sample's original state, making it indispensable for proteomics, histology, and drug testing research.

Advanced Food Science

While commercial food dehydrators are common, laboratory freeze dryers are used to develop high-end food products where quality is paramount. Freeze-dried food is extremely lightweight and retains nearly all of its original nutritional value, flavor, and texture.

The final product rehydrates almost instantly, making it superior to traditionally dried foods. This technology is used for everything from astronaut meals to high-end backpacking food and gourmet ingredients.

Niche and Emerging Industries

The principles of freeze drying apply to any industry dealing with delicate organic compounds. For example, the cannabis industry uses it to dry and cure cannabis flowers, preserving volatile compounds like terpenes and cannabinoids that are easily lost with conventional drying methods.

Understanding the Trade-offs and Considerations

The Cost of Precision

Laboratory freeze dryers are sophisticated, energy-intensive, and expensive pieces of equipment. Their operational costs are significantly higher than those of a simple laboratory oven or dehydrator.

The Time Commitment

The lyophilization process is methodical and slow. A single cycle can take anywhere from several hours to multiple days to complete, depending on the sample size and type. It is not a method for rapid dehydration.

The Importance of Correct Operation

Achieving a successful outcome requires a precise protocol. The material must be properly pre-frozen at the correct temperature, and the vacuum level must be carefully controlled throughout the cycle. An improperly run process can ruin the sample or yield an incomplete result.

Selecting the Right Equipment

Not all freeze dryers are the same. Key factors like the cold trap temperature, condenser capacity, and vacuum pump performance must be matched to the specific application to ensure the process is efficient and effective.

Making the Right Choice for Your Goal

When deciding if freeze drying is the appropriate method, consider the nature of your material and your ultimate objective.

- If your primary focus is long-term stability of biologics (vaccines, enzymes): Freeze drying is the industry standard for preserving biological activity for storage and transport.

- If your primary focus is sample integrity for analysis (tissue, proteins): Freeze drying is the gold standard for "locking" a sample's molecular structure in place for future study.

- If your primary focus is premium food quality and nutrition: Freeze drying provides superior results in texture, flavor, and nutrient retention compared to any other drying method.

- If your primary focus is simply removing water from a robust, non-sensitive substance: A faster and more cost-effective method, such as a vacuum oven, is likely a better choice.

By understanding its core principles, you can leverage freeze drying not just as a tool for dehydration, but as a precise method for preservation.

Summary Table:

| Application Area | Primary Use Case | Key Benefit |

|---|---|---|

| Pharmaceuticals & Biotech | Stabilizing vaccines, proteins, and injectable drugs | Long-term storage at room temperature, easy reconstitution |

| Scientific & Clinical Research | Preserving tissues, cells, and biological samples for analysis | Maintains sample integrity and molecular structure |

| Advanced Food Science | Creating high-quality, lightweight food products | Retains nutrition, flavor, and texture; quick rehydration |

| Niche Industries (e.g., Cannabis) | Drying delicate organic compounds | Preserves volatile compounds like terpenes and cannabinoids |

Ready to enhance your lab's capabilities with precision freeze drying? KINTEK specializes in high-performance laboratory freeze dryers and consumables, designed to meet the exacting demands of pharmaceutical, biotech, and research applications. Our equipment ensures optimal preservation of your sensitive materials, maximizing stability and efficiency. Contact us today to find the perfect lyophilization solution for your needs!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

People Also Ask

- What are some other applications of freeze dryers? Preserving Delicate Materials in Tech and Research

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- What is collapse in lyophilization? Prevent Structural Failure in Your Freeze-Drying Process

- How is freeze drying used in biological applications? Preserving Vital Biomaterials for Research & Pharma

- What problems should be avoided when using a lyophilizer? Prevent Product Collapse and Equipment Overload