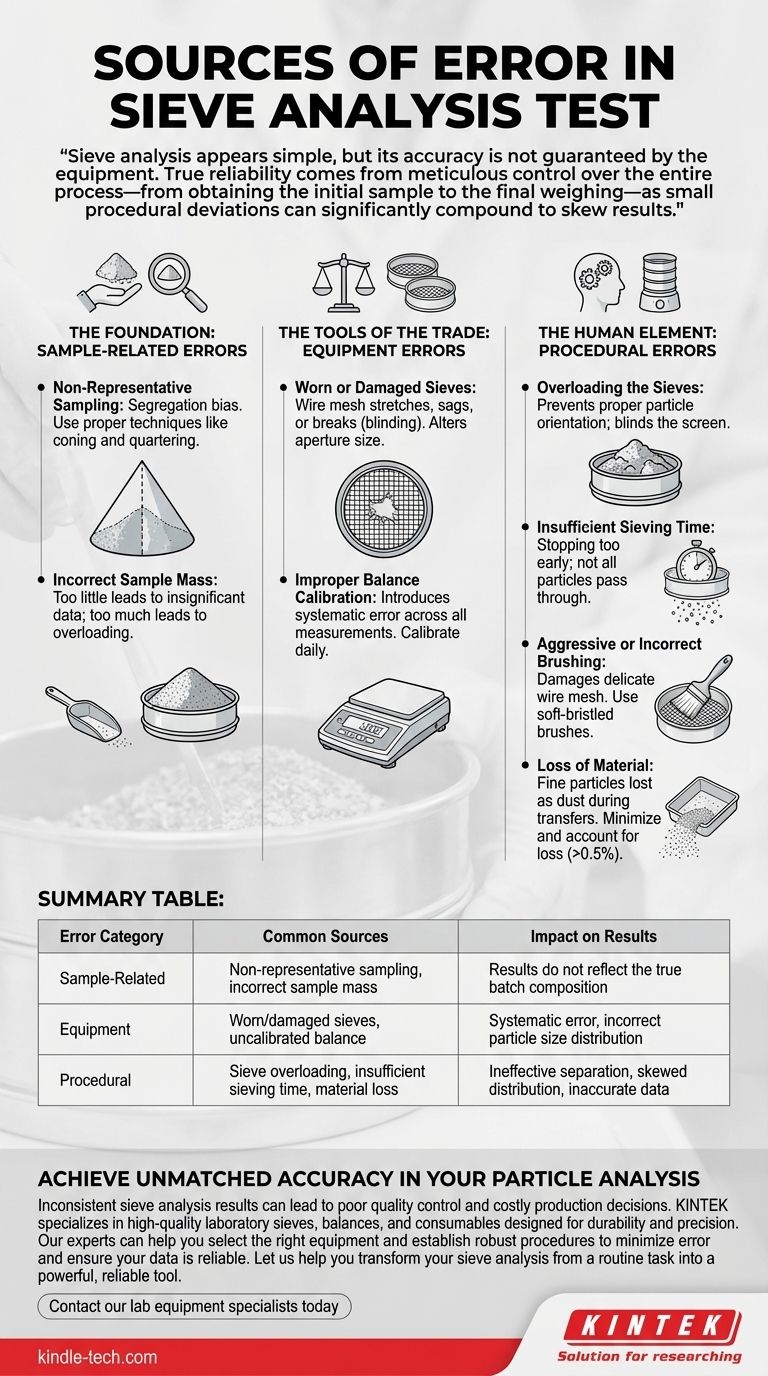

The primary sources of error in a sieve analysis test fall into three distinct categories: issues with the material sample itself, problems with the equipment, and mistakes in the procedure. Errors can arise from taking a non-representative sample, using worn or damaged sieves, overloading the screens, or not sieving for a sufficient amount of time.

Sieve analysis appears simple, but its accuracy is not guaranteed by the equipment. True reliability comes from meticulous control over the entire process—from obtaining the initial sample to the final weighing—as small procedural deviations can significantly compound to skew results.

The Foundation: Sample-Related Errors

The most critical errors often occur before the test even begins. If the initial sample is flawed, the results will be meaningless, regardless of how well the procedure is executed.

Non-Representative Sampling

The portion of material tested must accurately reflect the entire batch. Taking a sample just from the top of a pile, for instance, can lead to segregation bias, as finer particles tend to settle.

Proper techniques like coning and quartering are essential to create a smaller, truly representative sample for analysis.

Incorrect Sample Mass

Using too little material can result in statistically insignificant data, where the presence or absence of a few large particles can drastically alter the final distribution.

Conversely, using too much material for the sieve diameter leads to overloading, which is a major procedural error.

The Tools of the Trade: Equipment Errors

The physical condition and calibration of your equipment are non-negotiable prerequisites for accurate analysis.

Worn or Damaged Sieves

Over time, the wire mesh in a sieve can stretch, sag, or break, a condition known as blinding. This alters the aperture size, allowing larger particles to pass through or trapping smaller ones, corrupting the separation process.

Regular inspection of sieves with a magnifying lens or calibrated microscope is crucial for identifying damage.

Improper Balance Calibration

The entire analysis is based on mass. An uncalibrated or inaccurate balance will introduce a systematic error across all measurements, making the final particle size distribution incorrect.

Balances should be calibrated daily or before each use according to standard laboratory procedures.

The Human Element: Procedural Errors

This is where the operator's skill and attention to detail have the greatest impact. Most day-to-day errors in sieve analysis are procedural.

Overloading the Sieves

This is arguably the most common mistake. When too much material is placed on a sieve, the particles cannot properly orient themselves to pass through the apertures.

This creates a "bed" of material that blinds the screen, preventing effective separation and leading to an over-reporting of coarse particles.

Insufficient Sieving Time

Sieving must continue until the rate of particles passing through each sieve becomes negligible. Stopping the test too early means many particles have not had the chance to find an aperture.

The rule of thumb is to sieve until less than 1% of the material on a given sieve passes through it during a one-minute interval.

Aggressive or Incorrect Brushing

When cleaning sieves, harsh brushing can damage the delicate wire mesh, creating larger openings and invalidating the sieve for future tests.

Only soft-bristled brushes designed specifically for sieves should be used, with brushing motions parallel to the wires.

Loss of Material

Fine particles can be lost as dust during transfers between sieves and weighing pans. While small losses are inevitable, they must be minimized and accounted for.

A total mass loss of more than 0.5% between the initial and final summed weights often indicates a flawed test.

Common Pitfalls to Avoid

Understanding the trade-offs between speed and precision is key to maintaining data integrity in a real-world lab environment.

Ignoring the End-Point

Many operators simply run the shaker for a fixed time (e.g., 10 minutes) without confirming that separation is complete. This is a gamble.

The only way to be certain is to perform an end-point analysis by periodically stopping the test and weighing the pans until the weights stabilize.

Misinterpreting Agglomerates

Clumps of fine particles (agglomerates) can behave like large, single particles if they are not properly broken up before or during sieving. This is especially true for materials with moisture or electrostatic charge.

Wet sieving or adding anti-static agents may be necessary for certain materials to ensure you are measuring primary particles, not clumps.

Making the Right Choice for Your Goal

Your approach to minimizing error should match the required precision of your results.

- If your primary focus is research-grade precision or regulatory compliance: You must validate every step, from sampling protocol to confirming the sieving end-point for each material type.

- If your primary focus is routine production quality control: Standardize your procedure with a fixed sieving time and sample mass, but be aware that this introduces a potential trade-off in absolute accuracy for the sake of repeatability.

- If you are experiencing inconsistent results: The first places to investigate are always sample representativeness and sieve condition, as these foundational errors cannot be corrected by procedure alone.

Mastering these variables transforms sieve analysis from a routine task into a powerful and reliable analytical tool.

Summary Table:

| Error Category | Common Sources | Impact on Results |

|---|---|---|

| Sample-Related | Non-representative sampling, incorrect sample mass | Results do not reflect the true batch composition |

| Equipment | Worn/damaged sieves, uncalibrated balance | Systematic error, incorrect particle size distribution |

| Procedural | Sieve overloading, insufficient sieving time, material loss | Ineffective separation, skewed distribution, inaccurate data |

Achieve Unmatched Accuracy in Your Particle Analysis

Inconsistent sieve analysis results can lead to poor quality control and costly production decisions. KINTEK specializes in high-quality laboratory sieves, balances, and consumables designed for durability and precision. Our experts can help you select the right equipment and establish robust procedures to minimize error and ensure your data is reliable.

Let us help you transform your sieve analysis from a routine task into a powerful, reliable tool.

Contact our lab equipment specialists today for a consultation tailored to your specific materials and compliance needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the purpose of using a 200-mesh sieve prior to the component analysis of biomass? Enhance Purity & Protect HPLC

- What is sieve analysis for particle size distribution test? A Guide to Reliable Particle Sizing

- What is the maximum sieving deviation permitted? A Guide to ASTM & ISO Precision Limits

- What is sieve analysis of raw materials? Control Quality with Particle Size Data

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Which Cannot be separated by sieving? Understanding the Limits of Particle Size Separation

- What is the difference between ASTM standards sieves and is standard sieves? Ensure Compliance for Your Lab