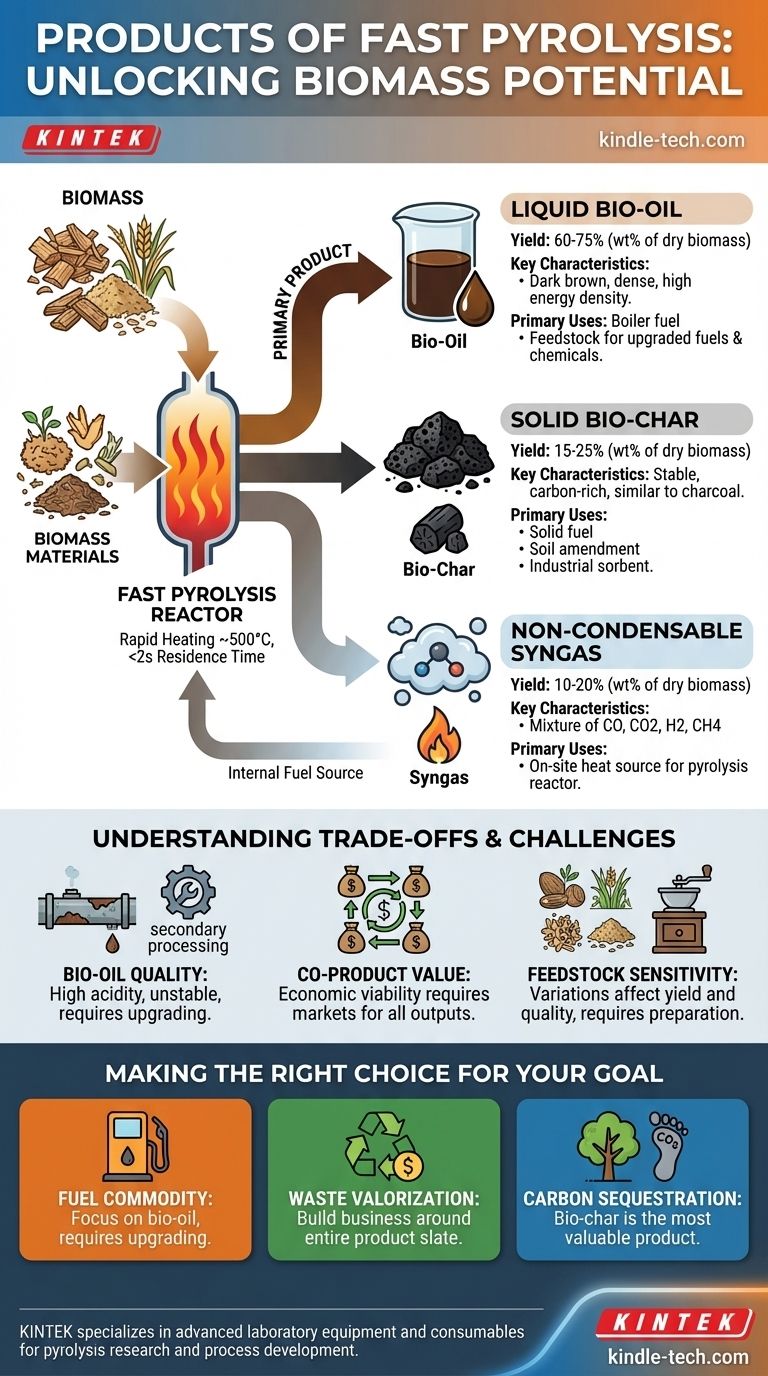

At its core, fast pyrolysis is a thermal decomposition process that rapidly heats organic material, like biomass, in the absence of oxygen. It intentionally breaks down this material to produce three distinct products: a liquid bio-oil, a solid bio-char, and a non-condensable synthesis gas (syngas). While all three are produced, the process is specifically optimized to maximize the yield of the liquid bio-oil.

The central purpose of fast pyrolysis is not just to break down biomass, but to convert its solid energy into a dense, transportable liquid fuel. The solid bio-char and combustible gases are best understood as valuable co-products that are often essential for the economic and energetic sustainability of the process itself.

The Three Core Products Explained

Fast pyrolysis operates at high temperatures (around 500°C) with a very short vapor residence time (typically less than 2 seconds). These specific conditions are designed to "crack" the biomass polymers and immediately quench the resulting vapors, maximizing the liquid yield.

Liquid Bio-Oil: The Primary Goal

Bio-oil, sometimes called pyrolysis oil or biocrude, is the main product, often comprising 60-75% of the output weight from dry biomass. It is a dark brown, dense liquid with a pungent, smoky odor.

This liquid is a complex mixture of hundreds of organic compounds, including water, acids, alcohols, and aldehydes. Its primary value lies in its high energy density compared to the original biomass, making it far easier and cheaper to store and transport. It can be used as a fuel for boilers and furnaces or upgraded into higher-grade liquid fuels and specialty chemicals.

Solid Bio-Char: The Carbon-Rich Residue

Bio-char is the stable, carbon-rich solid that remains after the volatile components have been driven off. It is essentially a form of charcoal and typically accounts for 15-25% of the product weight.

The properties of bio-char make it valuable in several applications. It can be burned as a solid fuel, used as an industrial sorbent, or applied to agricultural land as a soil amendment to improve fertility and sequester carbon in the ground for long periods.

Non-Condensable Gas: The Internal Fuel Source

The final product is a mixture of non-condensable gases, often called synthesis gas or syngas. This stream makes up 10-20% of the product weight and consists primarily of carbon monoxide (CO), carbon dioxide (CO2), hydrogen (H2), and methane (CH4).

While this gas can be collected, its most common and efficient use is to be redirected and burned on-site. This combustion provides the high heat required to run the pyrolysis reactor, significantly reducing the external energy required and improving the overall energy balance of the facility.

Understanding the Trade-offs and Challenges

While powerful, fast pyrolysis is not a simple solution. The nature of its products presents specific technical and economic hurdles that must be managed for a successful operation.

Bio-Oil Quality and Instability

Raw bio-oil is not a "drop-in" replacement for petroleum fuels. It is highly acidic, corrosive to standard pipes and engines, and can become unstable and thicken over time.

To be used as a transportation fuel, bio-oil requires significant and often costly secondary processing, known as upgrading. This step removes oxygen and stabilizes the oil, making it more compatible with existing fuel infrastructure.

The Co-Product Value Chain

A fast pyrolysis facility produces a slate of three products simultaneously. Economic viability rarely depends on the value of bio-oil alone.

An operator must have a clear strategy and established markets for all outputs. The value derived from selling bio-char and the energy savings from using the syngas internally are critical components of a successful business model.

Feedstock Sensitivity

The process is highly sensitive to the type and condition of the input biomass. Variations in moisture content, ash, and the chemical makeup of the feedstock can dramatically alter the yield and quality of the bio-oil and other products.

This requires careful feedstock preparation, such as drying and grinding, which adds to the operational complexity and cost of the overall system.

Making the Right Choice for Your Goal

Understanding the product slate is key to leveraging fast pyrolysis effectively for your specific objective.

- If your primary focus is producing a transportable energy commodity: Fast pyrolysis is the ideal technology, but you must account for the necessity and cost of bio-oil upgrading to meet fuel quality specifications.

- If your primary focus is waste valorization: Success depends on building a business model around the entire product slate, finding buyers or uses for both the bio-oil and the bio-char co-product.

- If your primary focus is carbon sequestration: The stable bio-char is your most valuable product, with the bio-oil and syngas serving as energy co-products that can make the sequestration process economically self-sustaining.

By viewing fast pyrolysis as a system that generates a portfolio of products, you can unlock its full potential to convert low-value biomass into high-value resources.

Summary Table:

| Product | Typical Yield (wt% of dry biomass) | Key Characteristics | Primary Uses |

|---|---|---|---|

| Bio-Oil (Liquid) | 60-75% | Dark brown, dense liquid; high energy density; complex mixture of organics. | Boiler fuel; feedstock for upgraded fuels/chemicals. |

| Bio-Char (Solid) | 15-25% | Stable, carbon-rich solid; similar to charcoal. | Solid fuel; soil amendment; industrial sorbent. |

| Syngas (Non-Condensable) | 10-20% | Mixture of CO, CO2, H2, CH4; combustible. | On-site heat source for the pyrolysis reactor. |

Ready to transform your biomass research or processing? The specific products of fast pyrolysis—bio-oil, bio-char, and syngas—require precise thermal control to maximize yield and quality. KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and process development. Our reactors and systems are designed to help you achieve optimal results, whether your goal is fuel production, waste valorization, or carbon sequestration. Contact our experts today to discuss how our solutions can enhance your biomass conversion projects.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the fuel gases from pyrolysis? Understanding the Key Byproduct for Energy Self-Sufficiency

- What is the advantage of pyrolysis? Transforming Waste into High-Value Biofuels and Biochar

- What are the factors affecting biomass pyrolysis? Master Temperature, Feedstock & Economics for Optimal Output

- What is the end product of pyrolysis? Transform Waste into Biochar, Bio-oil, and Syngas

- What are the advantages of a continuous furnace? Achieve High-Volume, Consistent Thermal Processing

- What is the composition of pyrolysis products? A Guide to Biochar, Bio-oil, and Syngas

- What are the three types of pyrolysis process? Slow, Fast, and Conventional Explained

- What are the methods of producing bio-oil? The Definitive Guide to Pyrolysis and Alternative Biofuel Processes