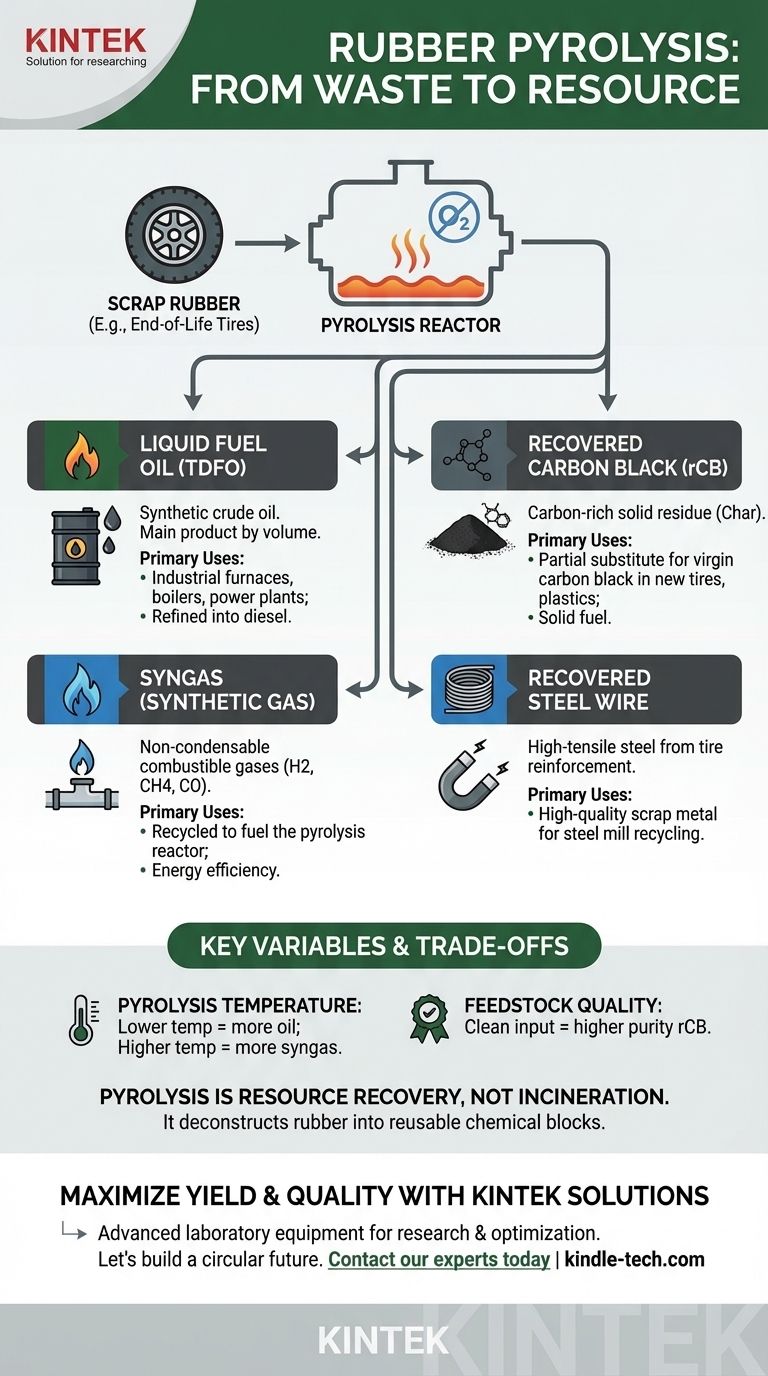

In short, rubber pyrolysis is a thermochemical process that breaks down scrap rubber, such as end-of-life tires, into three primary outputs: a liquid fuel oil, a solid carbon char, and a non-condensable synthetic gas. When processing tires, a fourth product, high-tensile steel wire, is also recovered.

Pyrolysis is fundamentally a resource recovery process, not just a waste disposal method. Unlike incineration, which destroys material for heat, pyrolysis deconstructs rubber into its constituent chemical building blocks, which can be reused as fuels, industrial carbons, and recycled metals.

How Pyrolysis Transforms Rubber

Pyrolysis works by heating materials to high temperatures in an oxygen-free environment. The absence of oxygen is critical; it prevents the rubber from burning (combusting) and instead forces its complex long-chain polymer molecules to break down into smaller, more valuable substances.

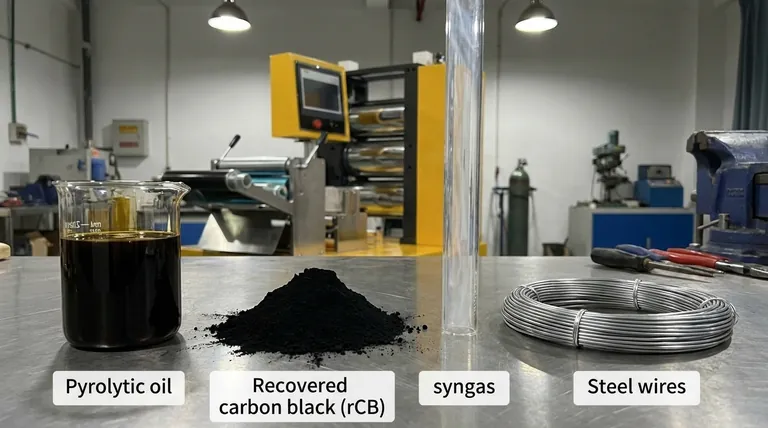

The Liquid Phase: Pyrolytic Oil

The most significant product by volume is often the liquid oil, sometimes called Tire-Derived Fuel Oil (TDFO). This substance is a type of synthetic crude oil.

It can be used directly as a heavy fuel oil in industrial furnaces, boilers, and power plants. With further refining, it can be upgraded into more valuable fuels like diesel.

The Solid Phase: Recovered Carbon Black (rCB)

After the volatile components have vaporized, a solid, carbon-rich residue remains. This is known as recovered carbon black (rCB) or char.

This material has value as a solid fuel, but its highest potential is as a partial substitute for virgin carbon black in the manufacturing of new tires, plastics, and other rubber goods. Its quality directly depends on the pyrolysis conditions and the purity of the incoming tires.

The Gas Phase: Syngas

The process also generates a stream of non-condensable gases, collectively known as syngas. This is a mixture of combustible gases like hydrogen (H2), methane (CH4), and carbon monoxide (CO), along with inert gases like carbon dioxide (CO2).

In most modern pyrolysis plants, this syngas is not wasted. It is captured and recycled back into the system to provide the energy needed to heat the pyrolysis reactor, making the process more self-sustaining and energy-efficient.

The Recovered Metal: Steel Wire

When the feedstock is vehicle tires, the embedded steel belts and beads are left behind with the solid char.

This high-quality steel wire is easily separated from the char using magnets. It is then cleaned and sold as a high-value scrap metal for recycling in steel mills.

Understanding the Key Variables and Trade-offs

The exact yield and composition of these products are not fixed. They are influenced by several factors, creating a series of operational trade-offs.

The Influence of Process Conditions

The pyrolysis temperature and heating rate are the most critical variables. Lower temperatures tend to maximize the yield of liquid oil, while very high temperatures favor the production of syngas. Controlling these conditions is key to optimizing the output for a specific economic goal.

Pyrolysis vs. Incineration

It is crucial to distinguish pyrolysis from incineration. Incineration is simply burning waste to generate heat, which can be used to create steam for electricity. It is a process of complete destruction that leaves behind ash.

Pyrolysis, on the other hand, is a process of deconstruction and value recovery. It breaks waste down into new raw materials that can be used to create other products, embodying a core principle of the circular economy.

Feedstock Purity and Product Quality

The quality of the final products, especially the recovered carbon black, is highly dependent on the cleanliness of the input material. Contaminants like dirt, moisture, and other non-rubber materials can end up in the char, reducing its purity and value.

Making the Right Choice for Your Goal

The "best" outcome of pyrolysis depends entirely on the primary objective of the operation.

- If your primary focus is energy generation: The pyrolytic oil and syngas are your most valuable outputs, serving as direct fuel sources for industrial processes or electricity production.

- If your primary focus is circular economy and material recovery: The recovered carbon black (rCB) and steel are the key products, as they can be reintroduced into manufacturing supply chains, reducing the need for virgin materials.

- If your primary focus is waste management: The key benefit is the massive reduction in landfill volume, transforming a problematic waste stream into a set of manageable, valuable commodities.

Ultimately, rubber pyrolysis offers a powerful technological pathway for converting a liability into a portfolio of assets.

Summary Table:

| Product | Description | Primary Uses |

|---|---|---|

| Pyrolytic Oil (TDFO) | A synthetic crude oil, the main liquid product. | Industrial fuel; can be refined into diesel. |

| Recovered Carbon Black (rCB) | A carbon-rich solid residue. | Fuel; partial substitute for virgin carbon black in new tires/plastics. |

| Syngas | A mixture of combustible non-condensable gases. | Recycled to fuel the pyrolysis reactor for energy efficiency. |

| Steel Wire | Recovered from tire feedstock. | High-quality scrap metal for recycling in steel mills. |

Ready to implement a sustainable rubber pyrolysis solution?

KINTEK specializes in advanced laboratory equipment and consumables for pyrolysis research and process optimization. Whether you are developing new methods or scaling up production, our products provide the precision and reliability you need to maximize the yield and quality of your outputs—from fuel oil to high-purity recovered carbon black (rCB).

Let's build a more circular future together. Contact our experts today to discuss how KINTEK can support your laboratory's specific needs in rubber pyrolysis and resource recovery.

Visual Guide

Related Products

- Small Lab Rubber Calendering Machine

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

People Also Ask

- Why is a multi-stage process necessary for E-waste analysis? Master Complex Sample Pre-treatment

- Why are ultrasonic cleaners or homogenizers required for electrocatalyst inks? Ensure Uniform Dispersion Today

- How much does a pyrolysis reactor cost? From $30k to $5M+ for Small to Industrial Plants

- What are the defects in sintered parts? Avoid Warping, Cracking, and Porosity Issues

- What are the methods of sample preparation in FTIR? Choose the Right Technique for Your Sample

- Which furnace is generally more efficient? Match the Right Furnace to Your Heating Goals

- How to measure optical properties of thin films? Master Spectroscopic Ellipsometry for Precise Results

- What are the components of pyrolysis oil? A Guide to Its Complex Bio-Crude Composition