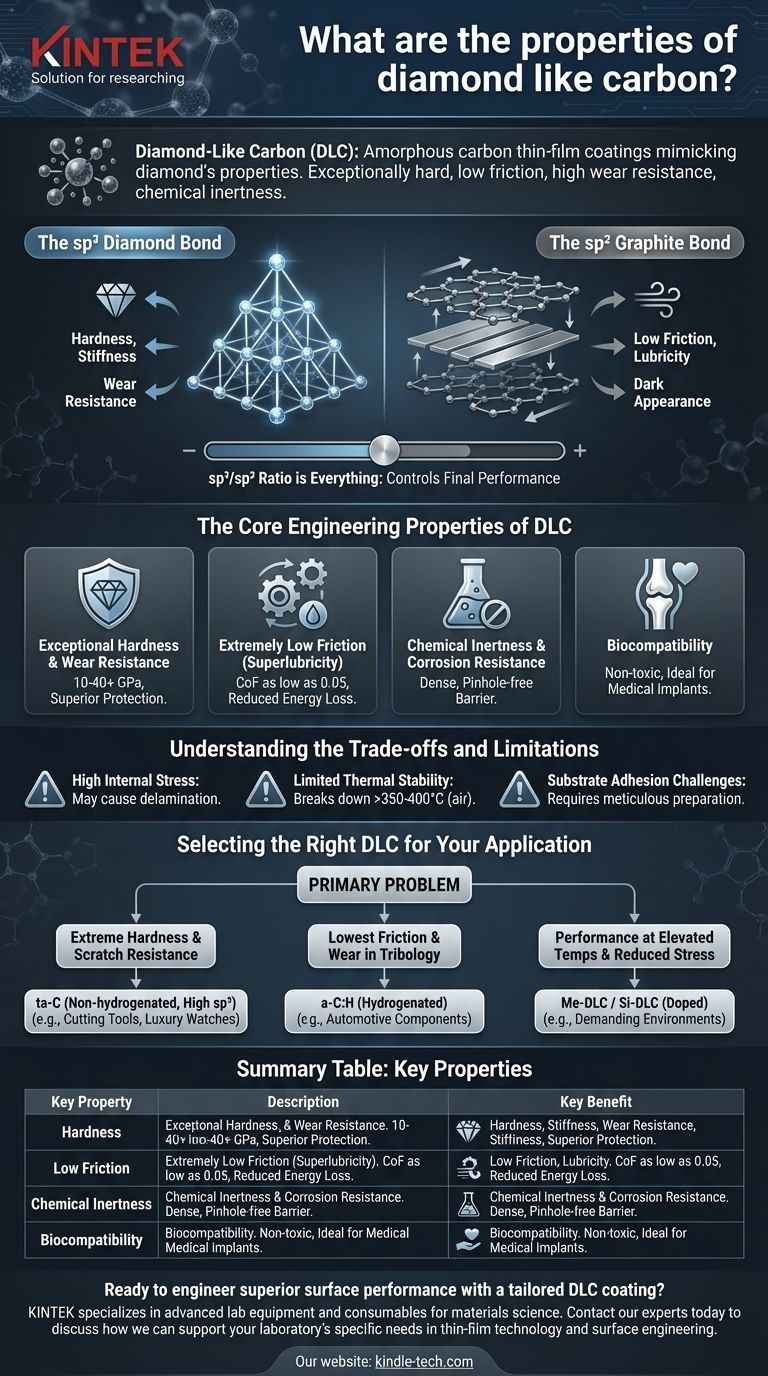

At its core, diamond-like carbon (DLC) is a class of amorphous carbon thin-film coatings prized for a unique combination of properties that mimic diamond. These include exceptional hardness, an extremely low coefficient of friction, high wear resistance, and chemical inertness, making it a powerful solution for demanding engineering applications.

The term "diamond-like carbon" doesn't describe a single material but a spectrum of coatings. Its properties are precisely tuned by controlling the internal ratio of hard, diamond-like (

sp³) atomic bonds to soft, graphite-like (sp²) bonds, which is the key to matching the coating to a specific technical challenge.

A Tale of Two Bonds: The Source of DLC's Properties

The remarkable characteristics of DLC arise from its unique internal structure. Unlike the pure crystalline structures of diamond or graphite, DLC is amorphous—a disordered mixture of two different types of carbon-to-carbon bonds.

The sp³ Diamond Bond

This is the tetrahedral bond found in natural diamond. It is incredibly strong and rigid, directly responsible for the hardness, stiffness, and wear resistance of a DLC coating.

The sp² Graphite Bond

This is the trigonal planar bond found in graphite. These bonds create layered sheets that slide easily against one another, which is what gives graphite its lubricity. In DLC, these bonds contribute to low friction and give the material its characteristic dark appearance.

Why the sp³/sp² Ratio is Everything

The final performance of a DLC coating is a direct result of the ratio between these two bond types. A higher percentage of sp³ bonds creates a harder, more "diamond-like" film. Conversely, a higher sp² content can result in a coating with lower internal stress and sometimes lower friction.

The Core Engineering Properties of DLC

Controlling the atomic structure allows engineers to achieve a range of valuable properties on the surface of a component.

Exceptional Hardness and Wear Resistance

DLC coatings are exceptionally hard, typically ranging from 10 to over 40 gigapascals (GPa), with some forms approaching the hardness of natural diamond (~100 GPa). This translates directly into superior protection against abrasive and adhesive wear.

Extremely Low Friction

DLC is one of the most lubricious materials known, with coefficients of friction against steel that can be as low as 0.05 in dry environments. This property, often called superlubricity, dramatically reduces energy loss and heat generation in moving parts.

Chemical Inertness and Corrosion Resistance

The dense, pinhole-free structure of DLC makes it an excellent barrier coating. It is inert to most acids, alkalis, and solvents, effectively protecting the underlying substrate from corrosion and chemical attack.

Biocompatibility

Carbon is a fundamental element in the human body. As a result, DLC coatings are highly biocompatible and non-toxic, making them ideal for medical implants like stents, orthopedic joints, and surgical tools where preventing adverse reactions is critical.

Understanding the Trade-offs and Limitations

While powerful, DLC coatings are not a universal solution. Understanding their limitations is critical for successful implementation.

High Internal Stress

Coatings with a very high percentage of sp³ bonds (the hardest forms of DLC) also exhibit high internal compressive stress. This stress can limit the practical thickness of the coating and may cause it to delaminate from the substrate if not managed with proper surface preparation and adhesion layers.

Limited Thermal Stability

Standard DLC coatings begin to break down and convert back to softer graphite (sp² carbon) at temperatures above 350-400°C in air. This limits their use in high-temperature applications unless they are doped with elements like silicon (Si) or tungsten (W) to improve thermal stability.

Substrate Adhesion Challenges

Achieving a strong bond between the DLC film and the component's surface is paramount. This often requires meticulous substrate cleaning and the use of a metallic or ceramic interlayer (like chromium or silicon) to ensure the coating adheres properly and performs as expected.

Selecting the Right DLC for Your Application

The choice of DLC depends entirely on the primary problem you need to solve.

- If your primary focus is extreme hardness and scratch resistance: A non-hydrogenated, high

sp³coating (known as tetrahedral amorphous carbon orta-C) is the best choice for applications like cutting tools or luxury watch components. - If your primary focus is the lowest possible friction and wear in tribological systems: A hydrogenated amorphous carbon (

a-C:H) coating is often ideal, particularly for automotive components like valve lifters and piston rings. - If your primary focus is performance at elevated temperatures or reduced internal stress: Consider a metal-doped (Me-DLC) or silicon-doped (Si-DLC) coating to enhance thermal stability and toughness for more demanding environments.

Ultimately, DLC is not a single product but a versatile platform for engineering surfaces with precisely tailored performance.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Hardness & Wear Resistance | Hardness up to 40+ GPa, approaching diamond. | Protects against abrasive and adhesive wear. |

| Low Friction (Superlubricity) | Coefficient of friction as low as 0.05. | Reduces energy loss and heat in moving parts. |

| Chemical Inertness | Dense, pinhole-free barrier against chemicals. | Excellent corrosion resistance for substrates. |

| Biocompatibility | Non-toxic and compatible with the human body. | Ideal for medical implants and surgical tools. |

Ready to engineer superior surface performance with a tailored DLC coating?

KINTEK specializes in advanced lab equipment and consumables for materials science, including the tools needed for developing and applying high-performance coatings like DLC. Whether you're in R&D or manufacturing, our solutions help you achieve the precise hardness, friction, and durability your project demands.

Contact our experts today to discuss how we can support your laboratory's specific needs in thin-film technology and surface engineering.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- Is diamond coating worth it? Maximize Component Life and Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability