At its core, biomass is a renewable energy source derived from organic materials such as wood, agricultural crops, and municipal solid waste. Its primary advantage is its ability to convert waste into energy within a theoretically carbon-neutral cycle. However, its significant disadvantages include potential air pollution, substantial land and water requirements, and the risk of contributing to deforestation if not sourced responsibly.

The central challenge with biomass is that its environmental benefit is not guaranteed. While it offers a renewable and dispatchable alternative to fossil fuels, its true sustainability hinges entirely on the source of its fuel and the technology used for conversion.

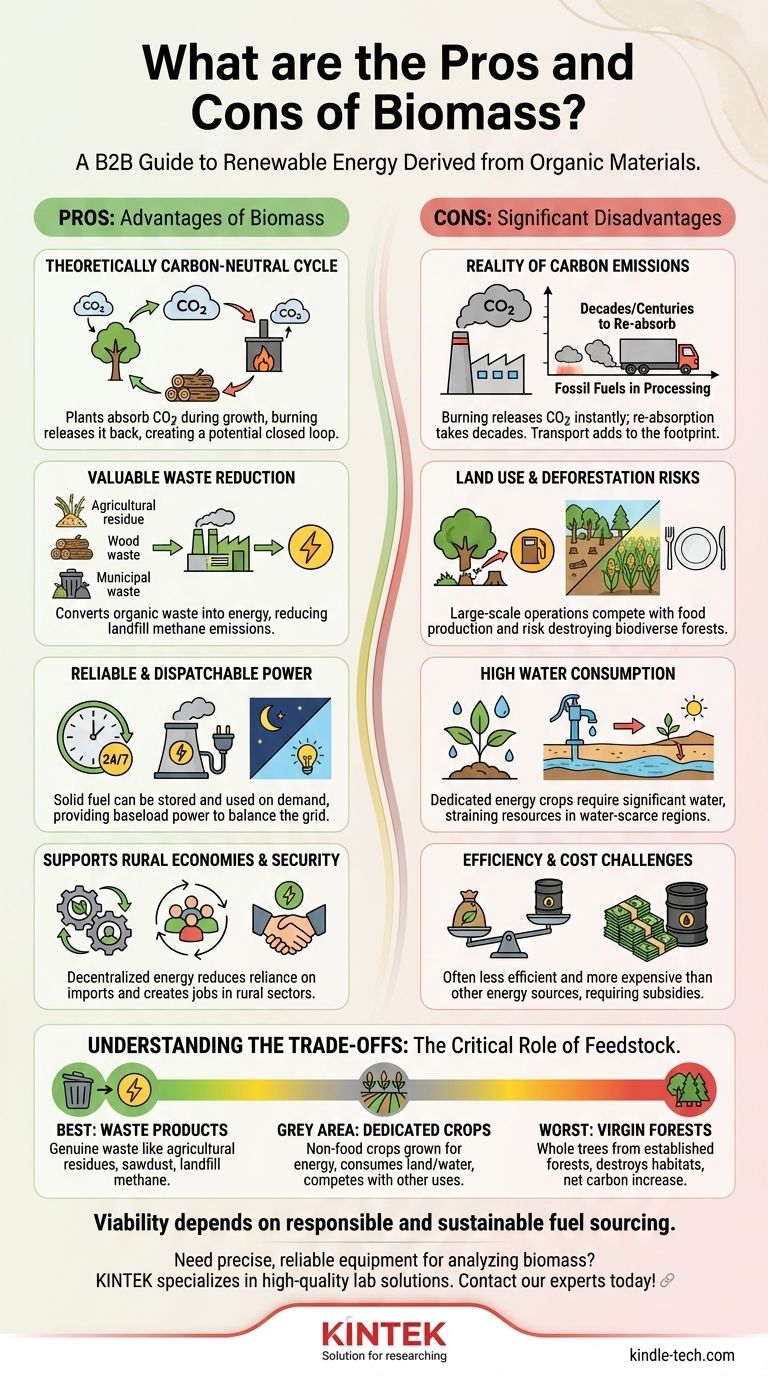

The Advantages of Biomass Energy

Biomass presents a compelling case as part of a diversified renewable energy portfolio due to its unique characteristics compared to other renewables.

A Theoretically Carbon-Neutral Cycle

The fundamental appeal of biomass is its role in the natural carbon cycle. Plants absorb carbon dioxide (CO2) during growth, and burning the resulting biomass releases that same CO2 back into the atmosphere.

In an ideal scenario, where new plants are grown to replace those harvested, the process creates a closed loop with no net increase in atmospheric CO2.

Valuable Waste Reduction

A significant portion of biomass fuel, or feedstock, comes from waste streams. This includes agricultural residue like corn stalks, wood waste from forestry operations, and organic materials from municipal solid waste.

Using these materials for energy solves a disposal problem, reduces landfill methane emissions (a potent greenhouse gas), and creates value from something that would otherwise be discarded.

Reliable and Dispatchable Power

Unlike intermittent renewable sources such as solar and wind, which only produce power under specific conditions, biomass is dispatchable.

The solid fuel can be stored and used to generate electricity on demand, 24/7. This makes it a valuable source of stable, baseload power that can help balance the grid.

Supports Energy Security and Rural Economies

Biomass is a decentralized energy source that can often be sourced locally. This reduces reliance on foreign energy imports and creates jobs in rural communities, particularly in agriculture and forestry sectors.

The Significant Disadvantages and Criticisms

The "green" credentials of biomass are heavily debated, and its implementation comes with serious environmental and logistical drawbacks.

The Reality of Carbon Emissions

The "carbon neutral" label is an oversimplification. Burning biomass releases CO2 at the point of combustion, and it can take decades or even centuries for new trees to grow and re-absorb that carbon.

Furthermore, harvesting, processing, and transporting biomass fuel requires energy, which often comes from fossil fuels, adding to the total carbon footprint. Biomass combustion also releases other harmful air pollutants like nitrogen oxides, volatile organic compounds, and particulate matter.

Land Use and Deforestation Risks

Large-scale biomass operations can create competition for land with food production, potentially driving up food prices and threatening food security.

The most severe risk is deforestation. If demand for biomass leads to the clearing of mature forests to create energy plantations or to harvest whole trees for fuel, it destroys ecosystems and releases massive amounts of stored carbon.

High Water Consumption

Growing dedicated biomass crops, such as switchgrass or miscanthus, requires significant amounts of water. In water-scarce regions, this can place an unsustainable strain on local aquifers and rivers, impacting both ecosystems and communities.

Efficiency and Cost

The process of converting biomass to electricity can be less efficient than with other fuel sources. The costs associated with harvesting, collection, and transportation can also make biomass more expensive than fossil fuels and even other renewables, often requiring government subsidies to be competitive.

Understanding the Trade-offs: The Critical Role of Feedstock

The environmental impact of biomass is not uniform; it exists on a spectrum defined entirely by the type of fuel used.

Best Case: Waste Products

The most sustainable form of biomass energy uses feedstocks that are genuine waste. This includes agricultural residues, sawdust from lumber mills, and methane captured from landfills. This approach avoids land-use conflicts and solves a pre-existing waste management problem.

The Grey Area: Dedicated Energy Crops

Growing non-food crops specifically for energy is a mixed bag. While it avoids direct deforestation, it still consumes significant land and water resources and competes with other potential land uses, including conservation and food production.

Worst Case: Virgin Forests

The most damaging and controversial source of biomass is whole trees harvested from established, biodiverse forests. This practice results in a net increase in atmospheric carbon for many decades, destroys critical habitats, and undermines the very climate goals that renewable energy is meant to achieve.

Making an Informed Assessment of Biomass

To evaluate a biomass project, you must look past the simple "renewable" label and analyze its specific feedstock and supply chain.

- If your primary focus is maximizing sustainability: Prioritize projects that use only waste-derived feedstocks from local sources to minimize transportation emissions and avoid land-use conflicts.

- If your primary focus is grid stability: Use biomass as a dispatchable power source to complement and balance the intermittency of solar and wind energy.

- If your primary focus is waste management: Integrate biomass energy production with agricultural, forestry, or municipal waste systems to create a circular economy.

Ultimately, the viability of biomass as a clean energy source depends entirely on a commitment to responsible and sustainable fuel sourcing.

Summary Table:

| Pros of Biomass | Cons of Biomass |

|---|---|

| Theoretically carbon-neutral cycle | Not truly carbon-neutral in practice |

| Converts waste into energy | Risk of deforestation and habitat loss |

| Reliable, dispatchable power | High water consumption for energy crops |

| Supports rural economies and energy security | Releases air pollutants (NOx, VOCs, particulate matter) |

| Reduces landfill methane emissions | Can be less efficient and more costly than other energy sources |

Need precise, reliable equipment for analyzing biomass feedstocks or optimizing energy conversion processes? KINTEK specializes in high-quality lab equipment and consumables tailored for renewable energy research, environmental testing, and sustainable material analysis. Our solutions help you accurately assess biomass sustainability, monitor emissions, and improve process efficiency. Contact our experts today to find the right tools for your biomass energy projects!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Proton Exchange Membrane for Batteries Lab Applications

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is the necessity of high-shear emulsifiers in silver nanoparticle coatings? Achieve Perfect Dispersion Today

- What are the surface protection techniques? Enhance Durability and Performance for Your Components

- What is the function of a laboratory drying oven for QPVA nanofiber membranes? Achieve Structural Stability with Precision

- What is the effect of pressure in sputtering? Master Particle Energy for Superior Film Quality

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What are the basic components of an IR spectrometer? A Guide to the Core Parts of FTIR Instruments

- What are the components of a rotavap? Master Gentle Evaporation for Sensitive Compounds

- What is the advantage of magnetron sputtering? High-Quality, Dense Thin Films at High Deposition Rates