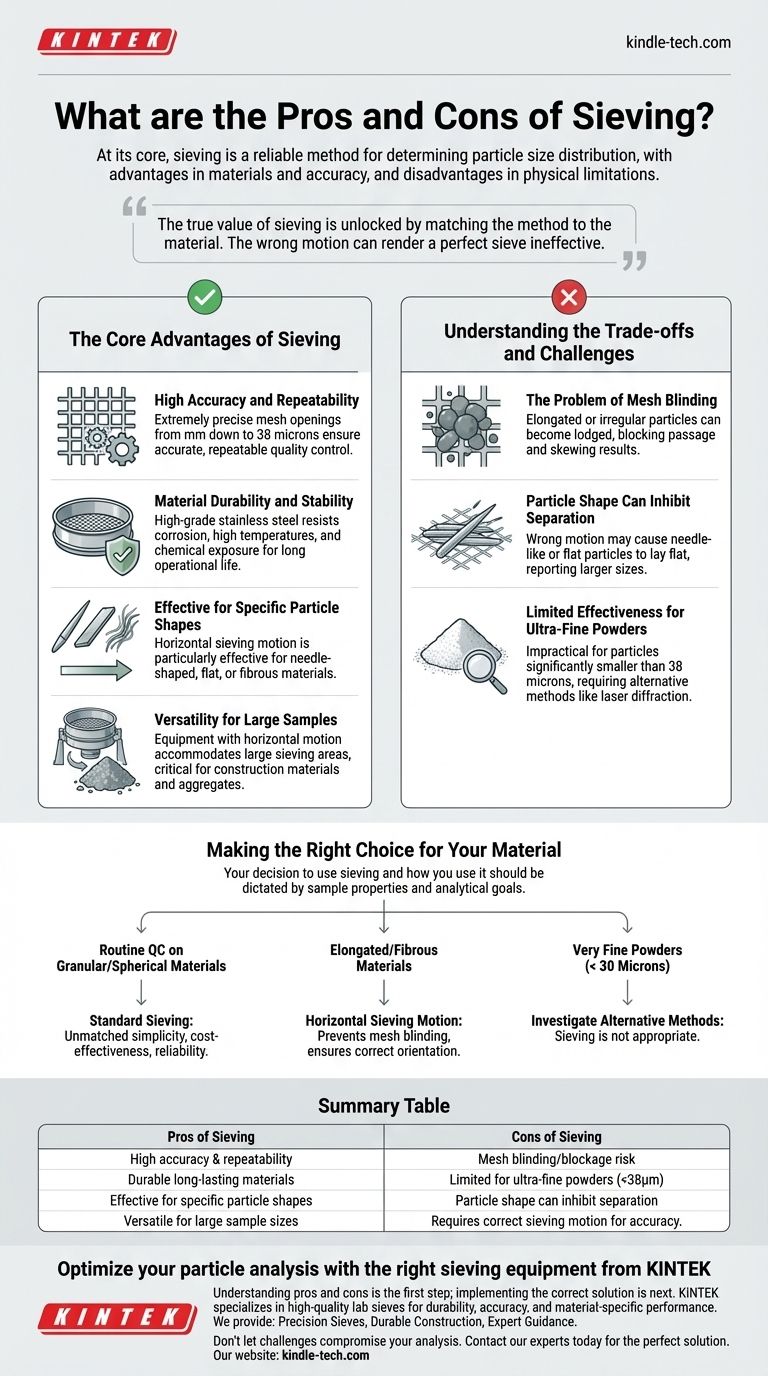

At its core, sieving is a highly reliable and straightforward method for determining particle size distribution. Its primary advantages are the use of durable, high-quality materials that ensure accurate and repeatable tests, while its main disadvantages stem from the physical limitations of the process, such as mesh blockage and difficulties with certain particle shapes.

The true value of sieving is unlocked not just by the equipment itself, but by matching the sieving method to the specific characteristics of the material being analyzed. The wrong motion can render an otherwise perfect sieve ineffective.

The Core Advantages of Sieving

Sieving remains a cornerstone of particle analysis in many industries due to its fundamental strengths in reliability, durability, and versatility.

High Accuracy and Repeatability

Sieves are manufactured with extremely precise mesh openings, with standard sizes ranging from several millimeters down to as fine as 38 microns. This precision ensures that results are both accurate and easily repeatable for quality control purposes.

Material Durability and Stability

Modern lab sieves are typically constructed from high-grade stainless steel. This provides excellent resistance to corrosion, high temperatures, and chemical exposure, making them easy to clean and ensuring a long operational life without degradation.

Effective for Specific Particle Shapes

For particles that are needle-shaped, flat, or fibrous, specific sieving methods can be highly advantageous. A horizontal sieving motion, for example, is particularly effective for these materials.

Versatility for Large Samples

The design of sieving equipment, especially those using a horizontal motion, can accommodate large sieving areas. This allows for the analysis of large sample amounts, which is critical in fields like the analysis of construction materials and aggregates.

Understanding the Trade-offs and Challenges

Despite its benefits, sieving has inherent limitations that a user must understand to avoid inaccurate results. These challenges are not failures of the method, but rather operational boundaries.

The Problem of Mesh Blinding

The most common challenge is mesh blinding, or blockage. Elongated or irregularly shaped particles can become lodged in the mesh openings, preventing other particles from passing through and skewing the final results.

Particle Shape Can Inhibit Separation

If the wrong sieving motion is used, needle-like or flat particles may not orient themselves correctly to pass through the mesh. They can lay flat across the openings, effectively reporting a larger size than their narrowest dimension would suggest.

Limited Effectiveness for Ultra-Fine Powders

While sieving is excellent for a wide range of particle sizes, it becomes impractical for very fine powders. Once particles are significantly smaller than 38 microns (into the sub-micron or nano range), other methods like laser diffraction become necessary.

Making the Right Choice for Your Material

Your decision to use sieving, and how you use it, should be dictated entirely by the properties of your sample material and your analytical goals.

- If your primary focus is routine QC on granular or spherical materials: Standard sieving offers an unmatched combination of simplicity, cost-effectiveness, and reliability.

- If you are analyzing elongated or fibrous materials: You must use a horizontal sieving motion to prevent mesh blinding and ensure particles orient correctly to pass through the mesh.

- If your goal is to analyze very fine powders below 30 microns: Sieving is not the appropriate tool, and you should investigate alternative particle analysis methods.

By understanding these capabilities and limitations, you can effectively leverage sieving as a powerful and precise tool for particle analysis.

Summary Table:

| Pros of Sieving | Cons of Sieving |

|---|---|

| High accuracy & repeatability | Mesh blinding/blockage risk |

| Durable, long-lasting materials | Limited for ultra-fine powders (<38μm) |

| Effective for specific particle shapes | Particle shape can inhibit separation |

| Versatile for large sample sizes | Requires correct sieving motion for accuracy |

Optimize your particle analysis with the right sieving equipment from KINTEK.

Understanding the pros and cons of sieving is the first step; implementing the correct solution is the next. KINTEK specializes in high-quality lab sieves and equipment designed for durability, accuracy, and material-specific performance. Whether you're in quality control, construction materials, or research, our expertise ensures you get reliable, repeatable results.

We provide:

- Precision Sieves: Manufactured to exacting standards for accurate particle size distribution.

- Durable Construction: Stainless steel sieves resistant to corrosion, heat, and chemicals.

- Expert Guidance: Help in selecting the right sieving method and equipment for your specific material—be it granular, fibrous, or elongated particles.

Don't let sieving challenges compromise your analysis. Contact our experts today to find the perfect sieving solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the disadvantages of sieving? Key Limitations for Accurate Particle Analysis

- What are the two methods of sieve analysis? Choose the Right Method for Accurate Particle Sizing

- How accurate is a test sieve? Ensure Reliable Particle Size Analysis

- What are the limitations of sieve size analysis? Avoid Costly Errors in Particle Characterization

- Why sieve analysis test is important for soils? Unlock Your Soil's Engineering Potential

- What is the sieving method of separation? A Guide to Efficient Particle Size Classification

- What are the precautions for sieving method? Ensure Accurate Particle Size Analysis

- Why would you use a sieve on your soil sample? To Determine Grain Size Distribution for Engineering