In short, the main pyrolysis reactors are categorized by how they move material and transfer heat, including fixed-bed, fluidized-bed, rotary kiln, and auger reactors. Each design is engineered to control temperature and processing time, which directly determines whether the primary output is biochar, bio-oil, or syngas.

The specific type of pyrolysis reactor you use is the most critical decision in the entire process. It is not just a container for the reaction; the reactor's design fundamentally dictates the final product yields by controlling heating rates and residence time.

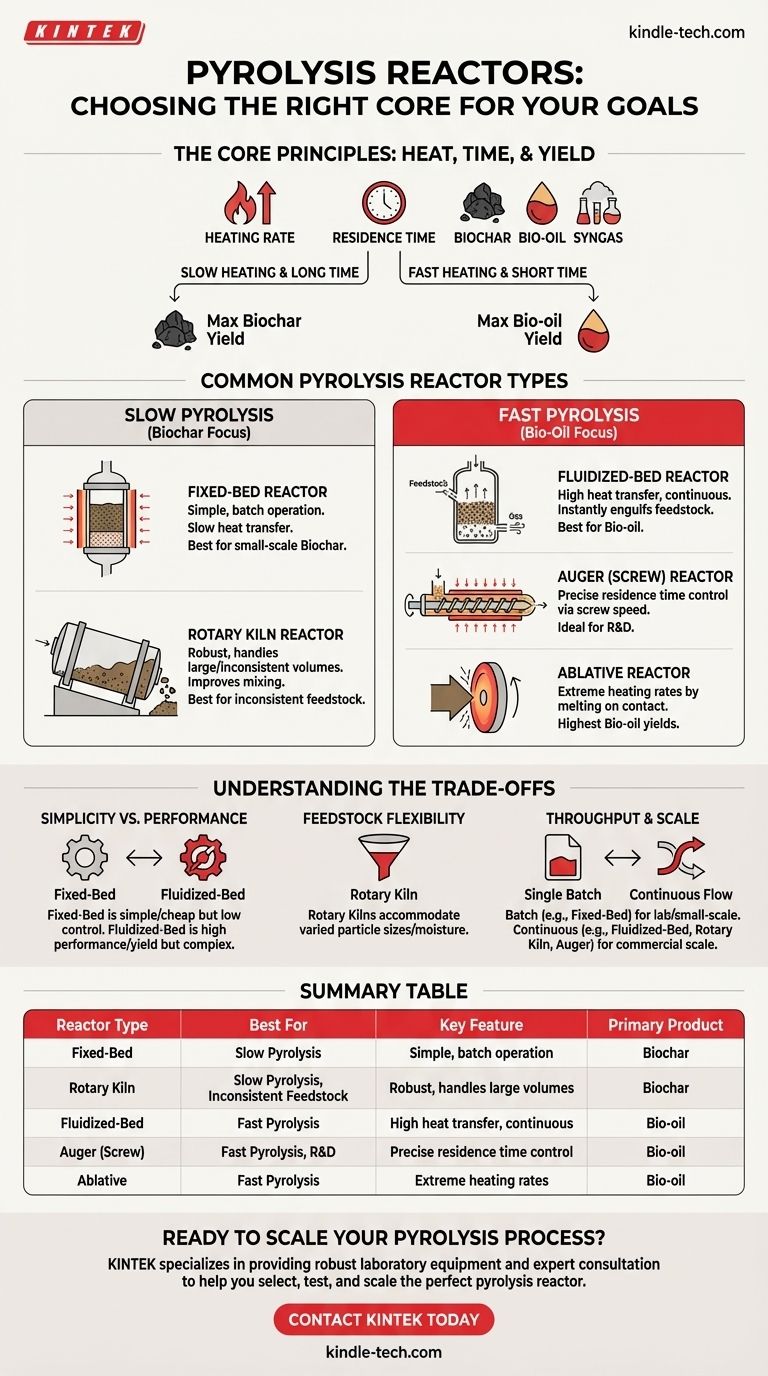

The Core Principles: Heat, Time, and Yield

The goal of any pyrolysis reactor is to thermally decompose a feedstock, like biomass or plastic, in an oxygen-free environment. The design of the reactor is an exercise in controlling three critical variables that determine the outcome.

The Role of Heating Rate

The speed at which the feedstock is heated to the target temperature is arguably the most important factor.

Slow heating rates allow for secondary reactions to occur, cracking larger vapor molecules and favoring the formation of solid biochar.

Fast heating rates (hundreds or thousands of degrees Celsius per second) minimize these secondary reactions. This rapidly vaporizes the material and allows the vapors to be cooled and collected, maximizing the yield of liquid bio-oil.

The Impact of Residence Time

Residence time is how long the material (solid feedstock and product vapors) stays inside the hot zone of the reactor.

A long residence time (minutes to hours), combined with slow heating, gives the material more time to convert into stable carbon, maximizing biochar.

A very short vapor residence time (typically less than two seconds) is crucial for fast pyrolysis. It ensures the valuable oil vapors are removed from the reactor before they can break down into non-condensable gases.

Common Pyrolysis Reactor Types Explained

While many specialized designs exist, most commercial and research systems are based on a few key concepts. Each is tailored for a specific pyrolysis process—slow or fast.

For Slow Pyrolysis (Biochar Focus)

These reactors use slower heating rates and longer residence times.

Fixed-Bed Reactors: This is the simplest design. The feedstock is loaded into a vessel and heated from the outside. Heat transfer is slow and inefficient, making it suitable for small-scale biochar production where process control is less critical.

Rotary Kiln Reactors: A large, rotating cylinder is set at a slight angle. Feedstock tumbles through as it rotates, which improves mixing and heat distribution compared to a fixed bed. Their robustness makes them excellent for handling large volumes of non-uniform feedstock.

For Fast Pyrolysis (Bio-Oil Focus)

These reactors are engineered for extremely rapid heat transfer and short vapor residence times.

Fluidized-Bed Reactors: Hot gas (or air) is forced up through a bed of sand or catalyst, causing the solid particles to behave like a boiling fluid. When feedstock is introduced, it is instantly engulfed by this hot, turbulent medium, achieving incredibly high heat transfer rates. This is a very common and effective technology for maximizing bio-oil.

Auger (or Screw) Reactors: The feedstock is conveyed through a heated tube by a rotating screw. This design offers precise control over residence time by adjusting the screw's rotation speed. Heat is transferred from the hot tube walls to the thin layer of material being moved by the screw.

Ablative Reactors: This unique design presses the feedstock against a very hot, rapidly moving surface. The material effectively melts and vaporizes on contact, achieving some of the highest possible heating rates. This results in high bio-oil yields but can be mechanically complex.

Understanding the Trade-offs

Choosing a reactor involves balancing complexity, cost, and performance against your specific goals and feedstock.

Simplicity vs. Performance

A fixed-bed reactor is mechanically simple and inexpensive to build. However, its poor heat transfer limits throughput and provides little control over the final product quality.

A fluidized-bed reactor offers superior performance and high bio-oil yields. This comes at the cost of higher complexity, higher energy consumption (for the fluidizing gas), and the need for more sophisticated control systems.

Feedstock Flexibility

Rotary kilns are the most forgiving. Their tumbling action can accommodate a wide range of particle sizes and moisture contents, making them ideal for materials like municipal solid waste or agricultural residues.

Fluidized-bed reactors, by contrast, demand a consistent and relatively small particle size to ensure proper fluidization and avoid clogging.

Throughput and Scale

Batch reactors, like many simple fixed-bed designs, process one load at a time, making them suitable only for lab-scale research or very small-scale production.

Fluidized-bed, auger, and rotary kiln reactors are all designed for continuous operation, making them the standard for any commercial-scale application with significant throughput requirements.

Making the Right Choice for Your Goal

Your choice of reactor must be driven by your desired primary product.

- If your primary focus is maximizing biochar yield: A slow pyrolysis reactor like a Rotary Kiln or a simple Fixed-Bed is your most direct path.

- If your primary focus is maximizing bio-oil yield: You must use a fast pyrolysis reactor, with the Fluidized-Bed being the most proven and scalable technology.

- If you are processing inconsistent or difficult feedstocks: The robust and forgiving nature of a Rotary Kiln makes it the superior choice.

- If you require precise control for research and development: An Auger Reactor offers unparalleled control over residence time, making it ideal for experimental work.

Ultimately, the reactor is the heart of the pyrolysis system, and selecting the correct design is the first step toward transforming your feedstock into valuable products.

Summary Table:

| Reactor Type | Best For | Key Feature | Primary Product |

|---|---|---|---|

| Fixed-Bed | Slow Pyrolysis | Simple, batch operation | Biochar |

| Rotary Kiln | Slow Pyrolysis, Inconsistent Feedstock | Robust, handles large volumes | Biochar |

| Fluidized-Bed | Fast Pyrolysis | High heat transfer, continuous | Bio-oil |

| Auger (Screw) | Fast Pyrolysis, R&D | Precise residence time control | Bio-oil |

| Ablative | Fast Pyrolysis | Extreme heating rates | Bio-oil |

Ready to Scale Your Pyrolysis Process?

Choosing the right reactor is critical to achieving your target yields of biochar, bio-oil, or syngas. KINTEK specializes in providing robust laboratory equipment and expert consultation to help you select, test, and scale the perfect pyrolysis reactor for your specific feedstock and product goals.

Our team can help you navigate the trade-offs between simplicity, performance, and feedstock flexibility to optimize your process efficiency.

Contact KINTEK today to discuss your project and discover how our lab solutions can accelerate your pyrolysis development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process