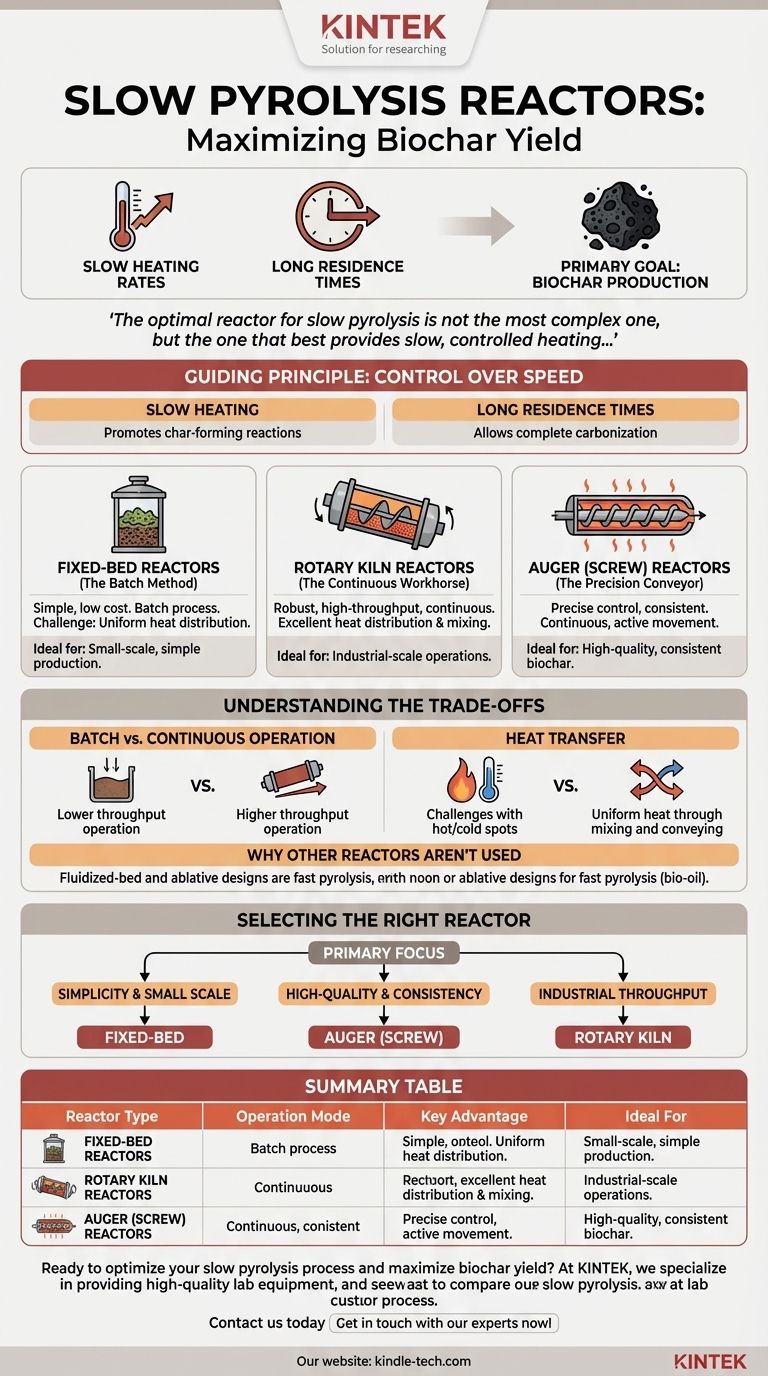

For slow pyrolysis, the most common reactors are fixed-bed, rotary kiln, and auger (or screw) types. While many pyrolysis reactor designs exist, these specific configurations are favored because they allow for the slow heating rates and long residence times necessary to maximize the primary goal of the process: producing a high yield of solid biochar.

The optimal reactor for slow pyrolysis is not the most complex one, but the one that best provides slow, controlled heating and allows biomass to remain at temperature for an extended period. This deliberate pace is what prioritizes the formation of stable solid char over liquid bio-oil or gas.

The Guiding Principle: Control Over Speed

The entire goal of slow pyrolysis is to convert biomass like wood, straw, or green waste into biochar. This requires a specific set of conditions that differ fundamentally from other pyrolysis methods.

Slow Heating Rates

Reactors must apply heat gradually. Rapid temperature increases would fracture the biomass molecules into smaller volatile compounds, which is the goal of fast pyrolysis for bio-oil production. Slow heating promotes secondary char-forming reactions.

Long Residence Times

The biomass must "reside" in the heated zone for an extended period, often for hours. This duration allows the carbonization process to complete fully, creating a stable, high-carbon solid product.

Common Reactor Designs for Slow Pyrolysis

Based on the need for slow heating and long residence times, three reactor types have become the industry standard for biochar production.

Fixed-Bed Reactors (The Batch Method)

In a fixed-bed reactor, a batch of biomass feedstock is loaded into a stationary container or chamber. Heat is then applied externally.

This design is valued for its simplicity and is common in smaller-scale or traditional wood charcoal operations. The lack of moving parts makes it relatively easy to build and operate, but achieving perfectly uniform heat distribution can be a challenge.

Rotary Kiln Reactors (The Continuous Workhorse)

A rotary kiln is a large, rotating cylindrical vessel, typically inclined at a slight angle. Biomass is fed into the higher end and slowly tumbles its way to the lower end as the kiln rotates.

The rotation ensures the feedstock is constantly mixed, which provides excellent heat distribution and produces a very consistent biochar. These are robust, high-throughput systems well-suited for industrial-scale continuous production.

Auger (Screw) Reactors (The Precision Conveyor)

An auger reactor uses a large screw mechanism to actively move feedstock through a heated tube or trough.

This design offers excellent control over the process. The residence time can be precisely managed by adjusting the screw's rotation speed, and the contained design ensures efficient heat transfer. This makes it a popular choice for operations requiring high consistency and control.

Understanding the Trade-offs

The choice of reactor involves balancing complexity, scale, and desired product quality. Not every reactor is suitable for every goal.

Batch vs. Continuous Operation

Fixed-bed reactors are inherently batch systems. They are simpler to operate but result in lower overall throughput and can have more variability between batches.

Rotary kilns and auger reactors are continuous systems. They offer higher throughput and greater product consistency but require more complex control systems and a larger capital investment.

Heat Transfer and Product Quality

A key challenge in fixed-bed reactors is avoiding hot spots and cold spots, which can lead to incomplete pyrolysis and an inconsistent final product.

The mixing action in rotary kilns and the conveying motion in auger reactors largely solve this problem, resulting in a more uniform and higher-quality biochar.

Why Other Reactors Aren't Used

Reactors like fluidized-bed or ablative designs are intentionally engineered for extremely high heat transfer rates. This makes them ideal for fast pyrolysis, where the goal is to vaporize the biomass quickly to maximize liquid bio-oil. For slow pyrolysis, their aggressive heating is counterproductive.

Selecting the Right Reactor for Your Goal

Your choice should be directly informed by your operational scale and primary objective.

- If your primary focus is simplicity and small-scale production: A fixed-bed reactor offers the most straightforward and cost-effective path to producing biochar.

- If your primary focus is high-quality, consistent biochar in a continuous process: An auger (screw) reactor provides superior control over temperature and processing time.

- If your primary focus is industrial-scale throughput and feedstock flexibility: A rotary kiln is the most robust solution for handling large volumes of diverse biomass.

Ultimately, matching the reactor's mechanics to your specific production goals is the key to successful slow pyrolysis.

Summary Table:

| Reactor Type | Operation Mode | Key Advantage | Ideal For |

|---|---|---|---|

| Fixed-Bed | Batch | Simplicity & Low Cost | Small-scale, simple production |

| Rotary Kiln | Continuous | High Throughput & Robustness | Industrial-scale operations |

| Auger (Screw) | Continuous | Precise Control & Consistency | High-quality, consistent biochar |

Ready to optimize your slow pyrolysis process and maximize biochar yield?

At KINTEK, we specialize in providing high-quality lab equipment, including pyrolysis reactors, to meet your specific research and production needs. Whether you're scaling up from a fixed-bed system or require the precision of an auger reactor, our experts can help you select the perfect solution for your biomass conversion goals.

Contact us today to discuss your project and discover how KINTEK's reliable equipment can enhance your lab's efficiency and results.

Get in touch with our experts now!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What is the significance of SCPW reactors for ODS steel? Evaluate Corrosion Resistance in Fusion Environments

- What role does a hydrothermal reactor with precision stirring play? Optimize Magnesium & Zinc Borate Synthesis

- How does the dual electric heater design in a laboratory batch reactor contribute to the pyrolysis process?

- What are the functions of pressure vessels and rapid decompression devices in the steam explosion (SE) process?

- Why is it necessary to ensure an oxygen-free environment in a pyrolysis reactor? Maximize Bio-Oil & Syngas Yields

- Why are industrial-grade high-pressure reactors necessary for the AFEX process? Unlock Biomass Conversion Potential

- What is the purpose of high-temperature sealant in high-pressure reactors? Ensure Leak-Free Gas Generation Reactions

- What is the purpose of the glass lined reactor? A Complete Guide to Corrosion Resistance and Purity