In short, the primary safety concerns of pyrolysis are the significant risk of fire and explosion from heating flammable materials to high temperatures, and the generation of toxic, unstable, and environmentally hazardous by-products. These risks demand highly controlled processes, specialized equipment, and rigorous safety protocols to manage effectively.

Pyrolysis is not inherently unsafe, but it is an unforgiving process. Its core safety challenge lies in managing the immense thermal energy and chemically reactive substances it creates. A comprehensive safety strategy must address the entire lifecycle, from feedstock handling and process control to product storage and emissions management.

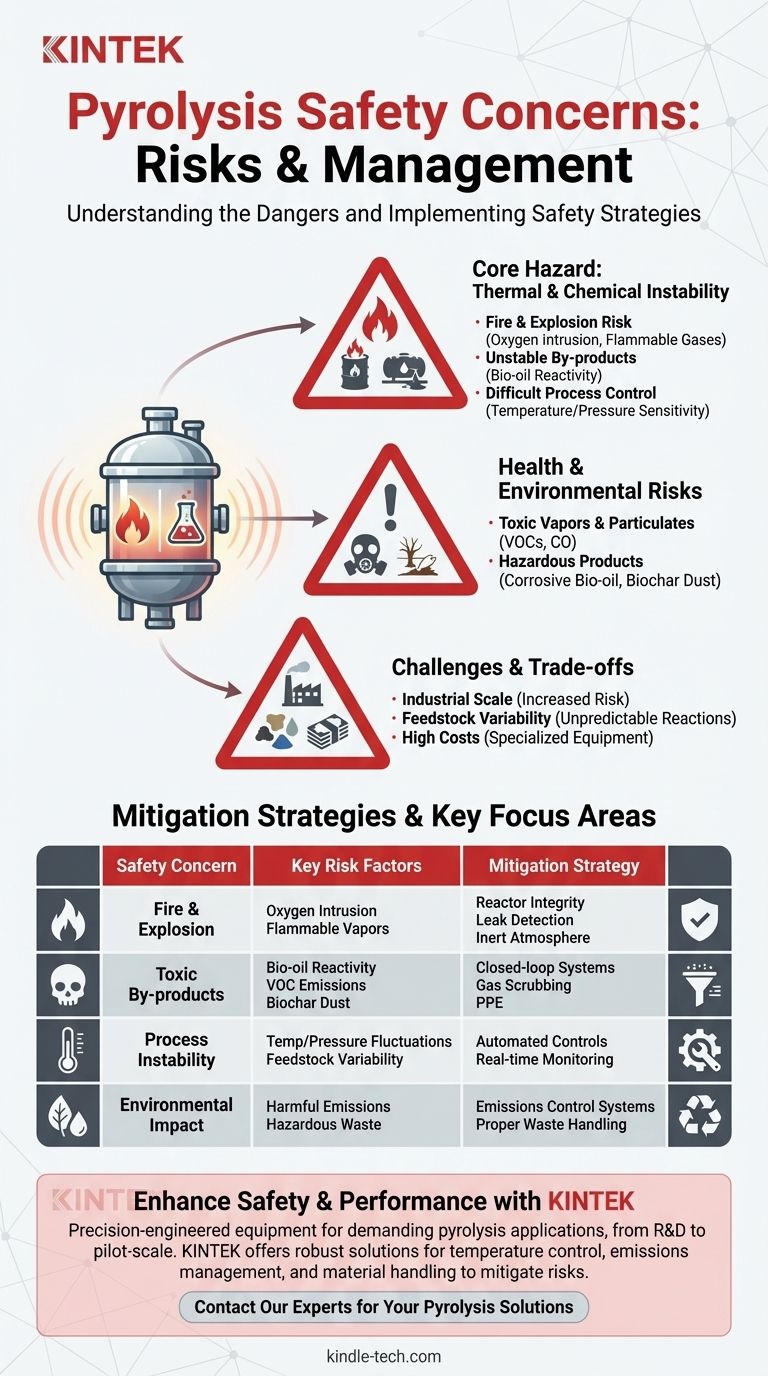

The Core Hazard: Thermal and Chemical Instability

The fundamental safety risks of pyrolysis stem directly from its core function: the thermal decomposition of material in an oxygen-limited environment. This process creates a high-energy, reactive state that must be carefully controlled.

Risk of Fire and Explosion

The most immediate and severe hazard is the potential for fire or explosion. The process intentionally generates flammable gases and vapors from the feedstock.

If oxygen is inadvertently introduced into the hot reactor—through a leak, seal failure, or improper procedure—these hot gases can ignite explosively. This makes the integrity of the pyrolysis reactor and associated piping paramount.

Unstable and Reactive By-products

The primary liquid product, often called pyrolysis oil or bio-oil, is not a stable substance like conventional crude oil. It is a complex mixture of reactive organic compounds.

Over time, this oil can continue to react with itself, leading to a gradual increase in viscosity or even solidifying. Heating the oil can accelerate these reactions, producing volatile organic compounds (VOCs) and solid residues, creating handling and storage hazards.

Difficult Process Control

High-temperature pyrolysis is a delicate balancing act. The specific chemical products generated are highly sensitive to temperature, pressure, and feedstock composition.

Without precise and robust control systems, the process can yield unpredictable and potentially more hazardous by-products. This necessitates sophisticated monitoring and automation, especially at an industrial scale.

Health and Environmental Exposure Risks

Beyond the immediate physical dangers, pyrolysis generates substances that pose significant health and environmental risks if they are not properly contained.

Emission of Toxic Vapors and Particulates

The process can release a range of harmful pollutants into the atmosphere. These include volatile organic compounds (VOCs), carbon monoxide, and fine particulate matter.

Proper gas handling and scrubbing systems are not optional; they are essential safety components required to protect operators and prevent environmental contamination.

Hazardous Nature of Products

The outputs themselves require careful handling. Bio-oil can be corrosive and may contain toxic or carcinogenic compounds depending on the feedstock.

Similarly, the solid biochar can exist as a fine dust, which poses a respiratory hazard and requires appropriate personal protective equipment (PPE) during handling.

Understanding the Trade-offs

Implementing a safe pyrolysis operation involves navigating several key challenges. Ignoring these realities is a common pitfall that can lead to project failure or a safety incident.

The Challenge of Scale

A process that is manageable in a controlled laboratory setting presents far greater risks at an industrial scale. Potential leak points multiply, the volume of flammable gas increases dramatically, and the consequences of a failure become much more severe.

The Impact of Feedstock Variability

Pyrolysis is often promoted for its ability to handle diverse feedstocks, but this flexibility is also a safety challenge. Different input materials will decompose differently, altering the composition and properties of the resulting oils and gases.

Safety protocols must be robust enough to account for this variability to avoid unexpected reactions or the creation of unanticipated toxic by-products.

High Equipment and Operating Costs

The need to manage high temperatures, control a sensitive chemical process, and contain hazardous substances dictates the use of high-quality, specialized equipment.

There is a significant capital investment required for a safe and reliable system. Attempting to cut costs on reactors, sensors, or safety interlocks directly translates to an increase in operational risk.

Making the Right Choice for Your Goal

Your approach to managing pyrolysis safety should be dictated by your primary objective.

- If your primary focus is industrial application: Prioritize investment in robust, automated process controls, comprehensive leak detection, and engineered fire suppression and emergency shutdown systems.

- If your primary focus is research and development: Implement strict lab safety protocols with an emphasis on small-scale containment, continuous atmospheric monitoring, and thorough chemical analysis of all outputs.

- If your primary focus is environmental impact: Your critical path is the design and validation of a comprehensive emissions control system to capture and treat all hazardous vapors and particulates.

Ultimately, safety cannot be an add-on; it must be a core principle integrated into the design and operation of any pyrolysis system.

Summary Table:

| Safety Concern | Key Risk Factors | Mitigation Strategy |

|---|---|---|

| Fire & Explosion | Oxygen intrusion, flammable gases/vapors | Reactor integrity, leak detection, inert atmosphere |

| Toxic By-products | Bio-oil reactivity, VOC emissions, biochar dust | Closed-loop systems, gas scrubbing, PPE |

| Process Instability | Temperature/pressure fluctuations, feedstock variability | Automated controls, real-time monitoring |

| Environmental Impact | Harmful emissions, hazardous waste | Emissions control systems, proper waste handling |

Ensure your pyrolysis process is safe and efficient with KINTEK's expertise.

Designing and operating a pyrolysis system requires precision-engineered equipment and a deep understanding of thermal process risks. KINTEK specializes in providing robust laboratory equipment and consumables tailored for demanding applications like pyrolysis R&D and pilot-scale operations. We help you mitigate risks with reliable solutions for temperature control, emissions management, and material handling.

Let us support your safety and innovation goals. Contact our experts today to discuss your specific needs and discover how KINTEK's products can enhance the safety and performance of your pyrolysis projects.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What is the function of a tube furnace? Achieve Precise High-Temperature Processing in a Controlled Atmosphere

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control