The sources for biochar production are incredibly diverse, spanning nearly any form of organic material. The primary categories are woody biomass from forestry and industry, agricultural residues like crop stalks and nutshells, animal manures, and other specialized organic waste streams such as biosolids or food waste. This wide range of inputs, known as feedstocks, is central to understanding biochar's potential.

The critical takeaway is not simply what can be used to make biochar, but that the choice of feedstock is the single most important factor determining the final biochar's chemical and physical properties. This choice dictates its suitability for any given application, from soil amendment to carbon sequestration.

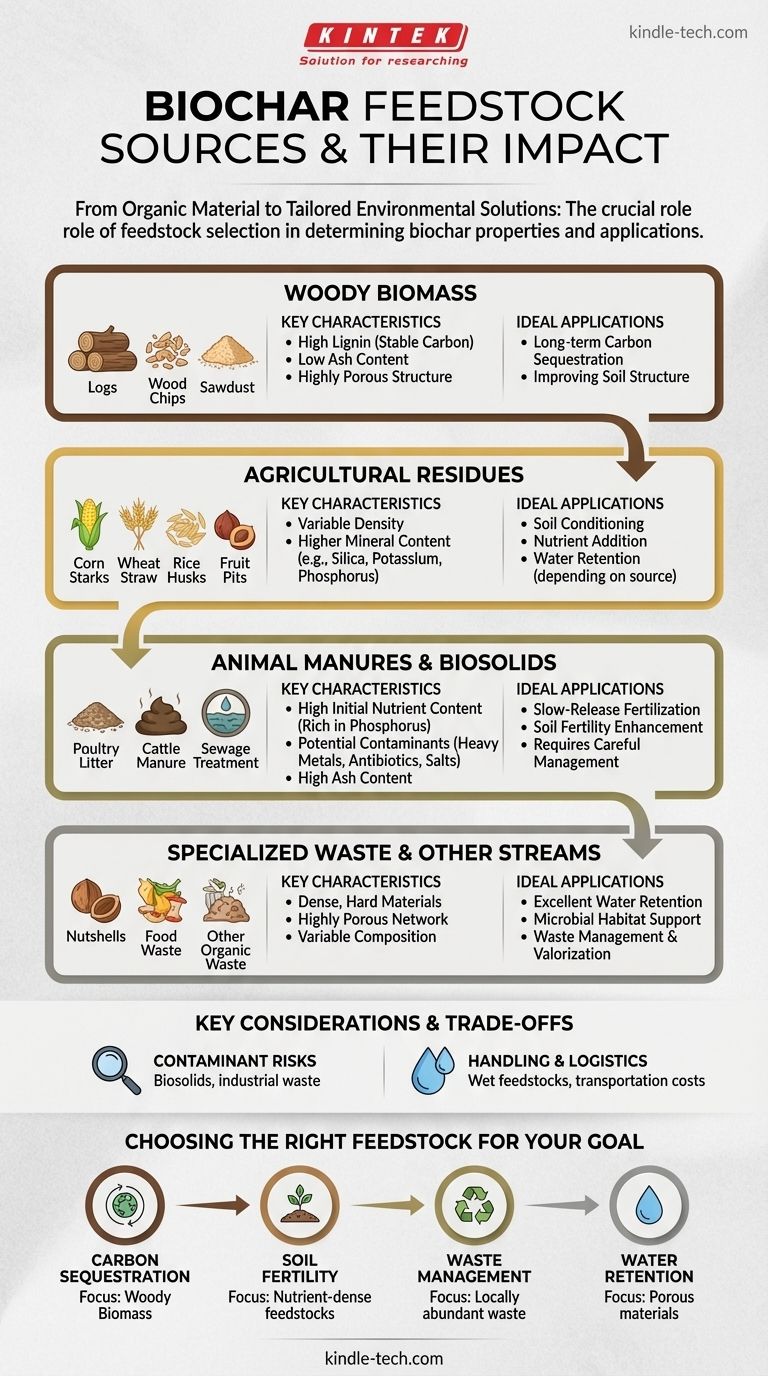

The Spectrum of Biochar Feedstocks

Biochar is created through pyrolysis, the process of heating organic material in a low-oxygen environment. The characteristics of the original material directly translate into the final product.

Woody Biomass

Sources include forestry byproducts, sawdust, wood chips, and untreated waste wood from construction. These feedstocks are high in lignin, a complex polymer that makes wood rigid.

Biochar from woody biomass is typically high in stable carbon, has low ash content, and possesses a highly porous structure. This makes it exceptionally effective for long-term carbon sequestration and improving soil structure.

Agricultural Residues

This is a broad category that includes materials left over from farming, such as corn stover, wheat straw, rice husks, nutshells, and fruit pits.

The properties of biochar from these sources vary widely. For example, biochar from straw may be less dense, while biochar from nutshells can be very hard and porous. They often contain higher levels of minerals like silica, potassium, and phosphorus compared to wood.

Animal Manures and Biosolids

Feedstocks like poultry litter, cattle manure, and processed sewage sludge can also be used. These materials are defined by their high initial nutrient content.

The resulting biochar is rich in nutrients, particularly phosphorus, making it act more like a slow-release fertilizer than a structural soil conditioner. However, this requires careful management.

How Feedstock Dictates Biochar Quality

The link between the input material and the output biochar is direct and predictable. Understanding this connection is key to producing biochar for a specific purpose.

Carbon Content and Stability

Feedstocks rich in lignin (like wood) produce biochar with a higher proportion of stable, aromatic carbon structures. This carbon resists decomposition for centuries, making it ideal for locking carbon away in the soil. Softer materials with less lignin produce a less stable biochar.

Nutrient Profile and Ash Content

The mineral content of the feedstock becomes concentrated in the biochar as ash. Manures and some crop residues are high in minerals, resulting in a nutrient-rich, high-ash biochar that can fertilize soil. Conversely, woody biomass is low in minerals, producing a low-ash, high-carbon biochar.

Porosity and Water Retention

The physical structure of the feedstock influences the pore structure of the final biochar. Hard, dense materials like nutshells can create biochar with a well-defined pore network, excellent for retaining water and providing a habitat for beneficial soil microbes.

pH and Liming Effect

Feedstocks containing high concentrations of alkali and alkaline earth metals (e.g., potassium, calcium, magnesium) will produce alkaline biochar. When added to acidic soils, this biochar can have a significant liming effect, raising the soil pH to levels more suitable for crop growth.

Understanding the Trade-offs and Contaminant Risks

While many organic materials can be used, not all are safe or practical. A technical assessment is non-negotiable.

The Issue of Contaminants

Feedstocks sourced from industrial processes, municipal waste, or certain agricultural operations can contain contaminants. Biosolids may carry heavy metals, and manures can have high salt content or residual antibiotics. Feedstock testing is essential to prevent soil contamination.

Handling and Pre-processing

The condition of the feedstock drastically impacts the efficiency of pyrolysis. "Wet" feedstocks like manure or food waste have high moisture content and require significant energy for drying before they can be processed, increasing costs and complexity.

Availability and Logistics

The theoretically "best" feedstock may not be the most practical. Transportation costs can be prohibitive for bulky, low-density materials like straw. The ideal feedstock is often one that is locally abundant, consistently available, and has a low acquisition cost.

Choosing the Right Feedstock for Your Goal

Your intended application must guide your feedstock selection.

- If your primary focus is carbon sequestration: Prioritize high-lignin, woody biomass to produce the most stable, high-carbon biochar possible.

- If your primary focus is soil fertility: Use nutrient-dense feedstocks like tested animal manures or specific crop residues to create a biochar that doubles as a slow-release fertilizer.

- If your primary focus is waste management: Target locally abundant, low-cost organic waste streams, turning a potential liability into a valuable soil amendment or carbon product.

- If your primary focus is improving water retention: Consider feedstocks known to produce highly porous biochars, such as certain nutshells or fibrous plant materials.

Ultimately, selecting the right feedstock transforms biochar from a generic product into a precision tool for your specific environmental or agricultural objective.

Summary Table:

| Feedstock Category | Key Characteristics | Ideal Biochar Application |

|---|---|---|

| Woody Biomass | High lignin, low ash, porous | Carbon sequestration, soil structure |

| Agricultural Residues | Variable density, higher mineral content | Soil conditioning, nutrient addition |

| Animal Manures & Biosolids | High nutrient content, potential contaminants | Slow-release fertilization |

| Specialized Waste (e.g., nutshells) | Dense, highly porous | Water retention, microbial habitat |

Ready to produce high-quality biochar tailored to your specific goals? At KINTEK, we specialize in advanced lab equipment and consumables for precise pyrolysis and feedstock analysis. Whether you're focusing on carbon sequestration, soil fertility, or waste management, our solutions help you optimize the process from feedstock selection to final product. Contact our experts today to discuss how we can support your biochar production and research needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Mesh belt controlled atmosphere furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds